Research - (2021) Volume 9, Issue 6

Time and Accuracy of 2 Different Intra Oral Scanners in 3 Different Finish Line Configurations

M Sai Teja Reddy*, Marian Ananad Bennis and Subhasree R

*Correspondence: M Sai Teja Reddy, Department of Prosthodontics, Saveetha Dental College, Saveetha Institute of Medical and Technical Sciences, Saveetha University Tamilnadu, India, Email:

Abstract

Purpose: The purpose of this in vitro study was to evaluate the time and accuracy of 2 CAD/CAM intraoral scanners in three different finish line configurations.

Material and methods: Typhoo models with three different finish line preparations are used, Supra Gingival, Equi Gingival and Sub Gingival finish line configuration. A total of 10 samples were prepared for each finish line configuration and with medit and 3 shape intraoral scanner and checked for the time taken for scanning.

Results: Statistically significant differences were not found between the scanners

Conclusion: With the limitations of the study, it can be concluded that compared to the medit scanner 3 shape Trios 3® is little faster in scanning

Keywords

CAD, CAM, Gingival health, Scaning

Introduction

Making an accurate dental impression is one of the most important and time-consuming processes in dental practice. During this process, it is important to ensure the reproduction of the intraoral environment as accurately as possible, as errors or inaccuracies can have far-reaching effects on the quality of the final restoration. Although improved on the regular impression material (for example, better taste, shorter set time), digital image processing is still considered uncomfortable for the patient and time consuming for the doctor. Balkenhol and colleagues have shown that the elastomeric test kits tested were more time consuming than those described by the manufacturer [1]. Creating traditional dental impressions of dental preparations using elastomeric materials is a task that is routinely encountered in today's dental practice. However, studies have shown that many of these traditional dental implants sent to dental laboratories are unsatisfactory due to defects such as voids and bubbles in the critical regions of this impression [2,3]. Moreover, the deformation and expansion of gypsum, used in the construction of stone dental casts, can further reduce the accuracy of this traditional dental restoration fabrication process [4].

Intraoral scanning has been available for almost a quarter of a century since the introduction of CEREC-1 as part of the single-seating appointment concept [5,6]. Computeraided design / computer-aided manufacturing (CAD/CAM) technology has brought a new range of dental techniques and materials. The technology has evolved since its introduction in the 1980s [7-9]. and is now part of daily practice. CAD / CAM systems generate high-quality reinforcements using industrially finished materials and standard manufacturing process [10]. Intraoral scanners (IOS) are powerful devices used for optical performance. They can collect information about the shape and size of dental arches (or the position of dental implants) by emitting light beams [10-12]. They present a ray of the light grid (structured light or laser) on the tooth's surface (or implant scan body) and are distorted by the camera through a high-resolution camera that passes such a beam or grid when these structures collide. The information collected by this camera is processed by powerful software that rearranges the desired three-dimensional (3D) model [13].

The traditional physical invention of the imprint of trays and materials (alginate, silicones, polyethers) represents a moment of discomfort for the patient [14,15]; This is primarily in the case of sensitive subjects, for example, those who are strongly reflexive [14-16]. In addition, it can be difficult for the clinician, especially in the case of technically complex impressions (for example, for the creation of long-term implant-supported reconstruction). The optical impression with IOS solves all these problems: the patient tolerates it well because it does not require conventional materials and is technically easier for the clinician. IOS allows immediate determination of impression quality; Patients receive virtual 3D models, which can be saved on a computer without infusing a plaster model and saves time and space and provides the ability to easily send models to the lab using e-mail, reducing time and cost. The clinician can save money on the purchase of imprint materials each year, the manufacture of individual trays, and the casting and shipping of plaster models; It is possible to store virtual models of patients without dedicating space to the clinic. Not least, the clinician may have a powerful marketing tool to communicate more effectively with the patient.

Materials and Methodology

Sample preparation

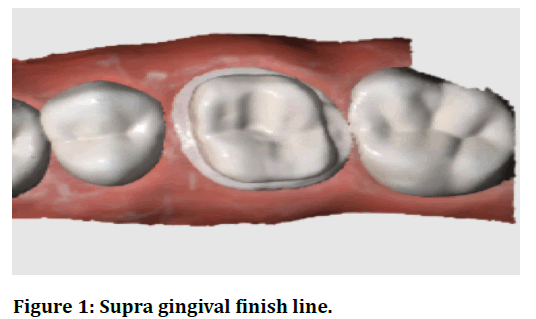

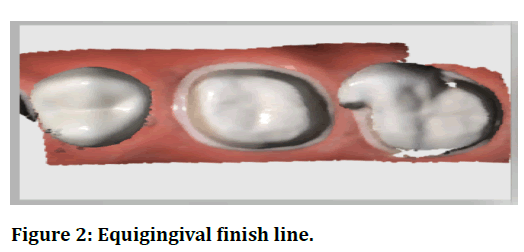

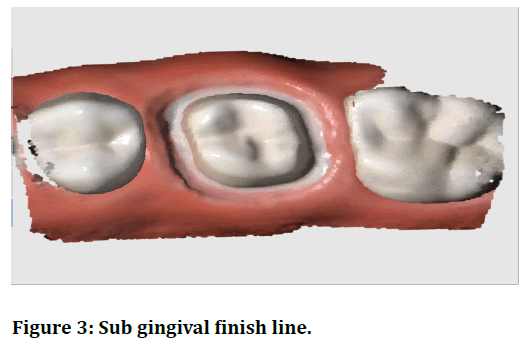

Typhoo models with three different finish line preparations are used. The three different finish line margins used are Supra Gingival, Equi Gingival and Sub Gingival and the shoulder finish line configuration is given in which the finish line has a wall perpendicular to the axial surfaces of the teeth. A total of 10 samples were prepared for each finish line configuration.

Methodology

The finished Typhoon model is scanned using intra-oral scanners and the scanners used in this study are MEDIT i500and 3 SHAPE (TRIOS 3). Scanning has been done twice for each prepared tooth; One without saliva and the other without saliva Trios 3® (3-shape, Copenhagen, Denmark).

Trios 3® is the third iOS to be fabricated by 3-shape, after Trios Standard (2011), producing monochrome images and Trios Color (2013). The Trios was unveiled at the International Dental Show (IDS) meeting in Cologne on March 25, 2015, and has been on the market since May 2015 in three different versions: the touch-screen trolley version, the dental treatment version unit and the USB version. This later version allows the clinician to use the laptop, in which the scanner is plugged in via a USB port; However, this connection is not straightforward (it requires many connecting cables) and therefore the scanner is not easily transport-capable. At the last IDS meeting in March 2017, a new wireless version of Trios3® was introduced: in this latest release, IOS will connect to a laptop or a traditional cart via Wi-Fi, eliminating the need to connect. The cable between the scanner rod and the computer. All the above versions are available with a straight pen-grip handle or pistol-shaped handle (320 x 56 x 16 mm). The Trios 3® is a powerful and extremely fast structured light scanner. It operates under the principle of confocal microscopy and ultrafast optical scanning; It is powder free and it creates highquality color images (Figure 1 to Figure 3).

Figure 1. Supra gingival finish line.

Figure 2. Equigingival finish line.

Figure 3. Sub gingival finish line.

Results

The descriptive results of the data from all the scanners and the value of every variable for scanner and the statistical differences for the variables between the scanners are summarized in Table 1. Statistically significant differences were not found between the scanners.

Discussion

The digital revolution is changing radically in the dental business, introducing a full range of devices, software and machines [17,18]. IOS is rapidly spreading to dental clinics, as there are significant advantages to their use [12]. IOS only allows optical impressions of teeth and implants using a beam of light. The optical impression is more comfortable for the patient [14,15,19] and easier to take for the clinician [20-24]. Therefore, they are rapidly aiding traditional impressions (with trays and materials), which will disappear in the next few years [11]. Each CAD/CAM process has several steps, each with a potential source of error. As a result, every CAD/CAM workflow process is especially important and can affect overall performance [10]. Some studies and literature reviews have shown that IOS can be a reliable tool for imprinting single and multiple abutments in dental patients [23-26]. Also, little is known about the quality of the various IOS currently available in the market. Only a few studies have compared the authenticity and accuracy of different IOS [27-33].

The objective of the present study was to assess two commonly used intraoral scanners that are crucial links in the chain of digital workflow in restoration design and manufacturing. The null hypothesis of the present study was that differences between scanners or types of scanners for each of the variables tested (Table 1) were not statistically significant.

| Finish line | Scanners | Mean | Standard deviation | P-Value |

|---|---|---|---|---|

| Supragingival finish line without saliva | Medit | 10.905 | 0.14706 | 0.046 |

| 3shape | 8.467 | 0.26512 | ||

| Supragingival finish line with saliva | Medit | 14.781 | 0.33848 | 0.231 |

| 3 Shape | 13.382 | 0.20911 | ||

| equigingival finish line without saliva | Medit | 16.019 | 0.61056 | 0.013 |

| 3 Shape | 12.668 | 0.20302 | ||

| equigingival finish line with saliva | Medit | 17.897 | 0.80522 | 0.009 |

| 3 Shape | 15.33 | 0.24716 | ||

| Subgingival finish line without saliva | Medit | 23.413 | 0.25342 | 0.848 |

| 3 Shape | 19.671 | 0.19451 | ||

| Subgingival finish line with saliva | Medit | 27.46 | 0.48141 | 0.498 |

| 3 Shape | 23.437 | 0.36356 |

Table 1: Table showing the mean and the standard deviation of the two intra scanners in three different finish line configurations. Was not statistically significant, proving that there is no difference between the two scanners.

Conclusion

With the limitations of the study, it can be concluded that compared to the medit scanner 3 shape Trios 3® is little faster in scanning the 3 different finish line configuration with and without saliva. Keeping future perspectives in mind, extensive research can be done by taking more samples, fabricating a prosthesis on the scanned tooth, and can be checked for the fit and marginal discrepancies. Further studies can also be done by incorporating more intra-oral scanners and scanning edentulous areas, implants.

References

- Balkenhol M, Wöstmann B, Kanehira M, et al. Shark fin test and impression quality: A correlation analysis. J Dent 2007; 35:409–15.

- Carrotte PV, Winstanley RB, Green JR. A study of the quality of impressions for anterior crowns received at a commercial laboratory. Br Dent J 1993; 174:235–40.

- Winstanley RB, Carrotte PV, Johnson A. The quality of impressions for crowns and bridges received at commercial dental laboratories. Br Dent J 1997; 183:209–13.

- Millstein PL. Determining the accuracy of gypsum casts made from type IV dental stone. J Oral Rehab 1992; 19:239–43.

- Otto T, De Nisco S. Computer-aided direct ceramic restorations: A 10-year prospective clinical study of Cerec CAD/CAM inlays and onlays. Int J Prosthodont 2002; 15:122–8.

- Mörmann WH. The evolution of the CEREC system. J Am Dent Assoc 2006; 137:7S-13S.

- Duret F, Preston JD. CAD/CAM imaging in dentistry. Curr Opin Dent 1991; 1:150–4.

- Strub JR, Rekow ED, Witkowski S. Computer-aided design and fabrication of dental restorations: Current systems and future possibilities. J Am Dent Assoc 2006; 137:1289–96.

- Goodacre CJ, Garbacea A, Patrick Naylor W, et al. CAD/CAM fabricated complete dentures: Concepts and clinical methods of obtaining required morphological data. J Prosthetic Dent 2012; 107:34–46.

- Prasad R, Al-Kheraif A. Three-dimensional accuracy of CAD/CAM titanium and ceramic superstructures for implant abutments using spiral scan microtomography. Int J Prosthodont 2013; 26:451–7.

- Zimmermann M, Koller C, Hickel R, et al. Chairside treatment of amelogenesis imperfecta, including establishment of a new vertical dimension with resin nanoceramic and intraoral scanning. J Prosthet Dent 2016; 116:309–13.

- Ting-shu S, Jian S. Intraoral digital impression technique: A review. J Prosthodont 2015; 24:313–21.

- Logozzo S, Zanetti EM, Franceschini G, et al. Recent advances in dental optics–Part I: 3D intraoral scanners for restorative dentistry. Optics Lasers Eng 2014; 54:203–21.

- Yuzbasioglu E, Kurt H, Turunc R, et al. Comparison of digital and conventional impression techniques: evaluation of patients’ perception, treatment comfort, effectiveness and clinical outcomes. BMC Oral Health 2014; 14.

- Wismeijer D, Mans R, van Genuchten M, et al. Patients’ preferences when comparing analogue implant impressions using a polyether impression material versus digital impressions (Intraoral Scan) of dental implants. Clin Oral Implants Res 2014; 25:1113–8.

- Means CR, Flenniken IE. Gagging: A problem in prosthetic dentistry. J Prosthetic Dent 1970; 23:614–20.

- van Noort R. The future of dental devices is digital. Dent Materials 2012; 28:3–12.

- Mangano F, Shibli JA, Fortin T. Digital dentistry: New materials and techniques. Int J Dent 2016; 2016:1–2.

- https://www.springer.com/gp/book/9783030659462

- Park HR, Park JM, Chun YS, et al. Changes in views on digital intraoral scanners among dental hygienists after training in digital impression taking. BMC Oral Health 2015; 15:1-7.

- Joda T, Brägger U. Time-efficiency analysis comparing digital and conventional workflows for implant crowns: A prospective clinical crossover trial. Int J Oral Maxillofac Implants 2015; 30:1047–53.

- Joda T, Brägger U. Digital vs. conventional implant prosthetic workflows: a cost/time analysis. Clin Oral Implants Res 2015; 26:1430–5.

- Tsirogiannis P, Reissmann DR, Heydecke G. Evaluation of the marginal fit of single-unit, complete-coverage ceramic restorations fabricated after digital and conventional impressions: A systematic review and meta-analysis. J Prosthetic Dent 2016; 116:328–35.e2.

- Ender A, Zimmermann M, Attin T, et al. In vivo precision of conventional and digital methods for obtaining quadrant dental impressions. Clin Oral Investigations 2016; 20:1495–504.

- Silva JSA, Almeida e Silva J, Erdelt K, et al. Marginal and internal fit of four-unit zirconia fixed dental prostheses based on digital and conventional impression techniques. Clin Oral Investigations 2014; 18:515–523.

- Chochlidakis KM, Papaspyridakos P, Geminiani A, et al. Digital versus conventional impressions for fixed prosthodontics: A systematic review and meta-analysis. J Prosthetic Dent 2016; 116:184–90.

- Patzelt SBM, Emmanouilidi A, Stampf S, et al. Accuracy of full-arch scans using intraoral scanners. Clin Oral Investig 2014; 18:1687–94.

- Renne W, Ludlow M, Fryml J, et al. Evaluation of the accuracy of 7 digital scanners: An in vitro analysis based on 3-dimensional comparisons. J Prosthetic Dent 2017; 118:36–42.

- Güth JF, Runkel C, Beuer F, et al. Accuracy of five intraoral scanners compared to indirect digitalization. Clin Oral Investigations 2017; 21:1445–55.

- Meer WJ van der, van der Meer WJ, Andriessen FS, et al. Application of intra-oral dental scanners in the digital workflow of implantology. PLoS ONE 2012; 7:e43312.

- Nedelcu RG, Persson ASK. Scanning accuracy and precision in 4 intraoral scanners: An in vitro comparison based on 3-dimensional analysis. J Prosthetic Dent 2014; 112:1461–71.

- Ajioka H, Kihara H, Odaira C, et al. Examination of the position accuracy of implant abutments reproduced by intra-oral optical impression. PLoS One 2016; 11:e0164048.

- Chew A, Esguerra R, Teoh KH, et al. Three-dimensional accuracy of digital implant impressions: effects of different scanners and implant level. Int J Oral Maxillofac Implants 2017; 32:70–80.

Author Info

M Sai Teja Reddy*, Marian Ananad Bennis and Subhasree R

Department of Prosthodontics, Saveetha Dental College, Saveetha Institute of Medical and Technical Sciences, Saveetha University Tamilnadu, IndiaCitation: M Sai Teja Reddy, Marian Ananad Bennis, Subhasree R, Time and Accuracy of 2 Different Intra Oral Scanners in 3 Different Finish Line Configurations, J Res Med Dent Sci, 2021, 9(6): 234-237

Received: 04-Jun-2021 Accepted: 21-Jun-2021