Research - (2020) Volume 8, Issue 1

Shear Bond Strength of Rebonded Self Ligating Ceramic Brackets after Different Reconditioning Procedures (A comparative an In vitro Study)

Zain Alabideen Ahmed1* and Mustafa M Al-Khatieeb2

*Correspondence: Zain Alabideen Ahmed, Ministry of Iraqi Health, Baghdad, Iraq, Email:

Abstract

Background: The aim of this study was to evaluate the effects of different recycling methods on shear bond strength and morphological changes of deboned mechanically retentive self-ligating ceramic brackets, then compare the findings with the new brackets of the same company.

Material and methods: Forty-eight Damon® Clear™ self-ligating ceramic brackets with a mechanical retentive base were divided into two groups; the first group contained twelve new ceramic brackets (the control group), while the second group contained thirty-six new brackets which were bonded to unetched and slightly wet buccal tooth surface to allow an easy debonding of these brackets by tweezer, these debonded brackets then divided into three experimental (recycled) groups (12 per group): Recycled by sandblasting, irradiation by an Er, Cr: YAG laser and irradiation by CO2 laser. After recycling, the 36 recycled brackets plus the twelve new brackets (the control) were bonded to the forty-eight premolar teeth again following standardized bonding procedure. The teeth were stored in distilled water at 37ËC for 24 hours, then thermal cycling was performed between 5ËC and 55ËC for 500 cycles, the exposure to each bath was 30 seconds, and the transfer time between the two baths was 5-10 seconds, the shear bond strength of all specimens was determined with a universal testing machine at a crosshead speed of 1 mm/min until bond failure occurred. The adhesive remnant index (ARI) was calculated under a stereomicroscope at X10 magnification. Morphological examinations of the recycled ceramic brackets bases were conducted with scanning electron microscopy.

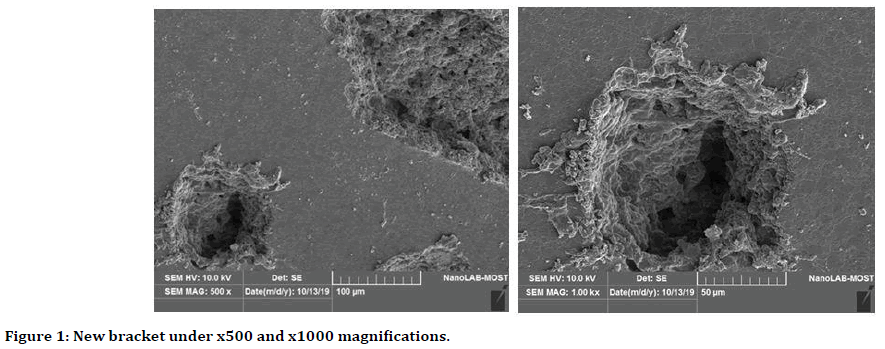

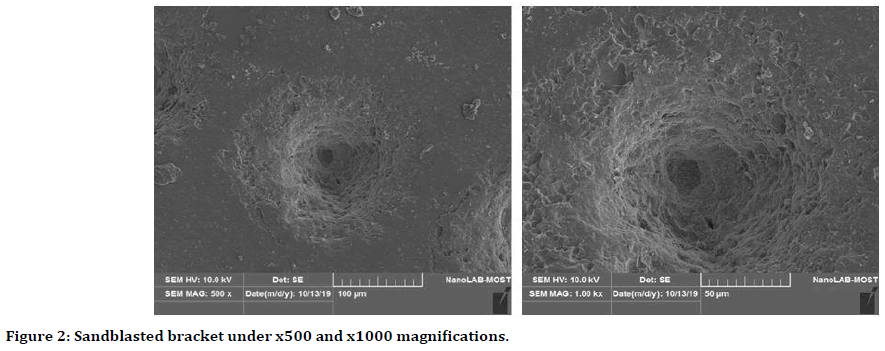

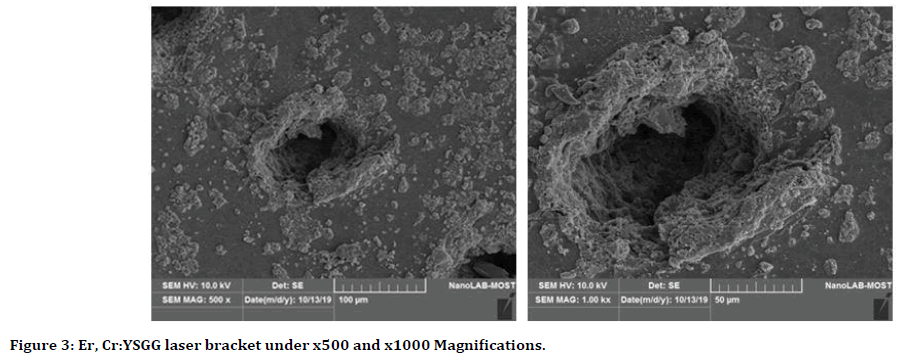

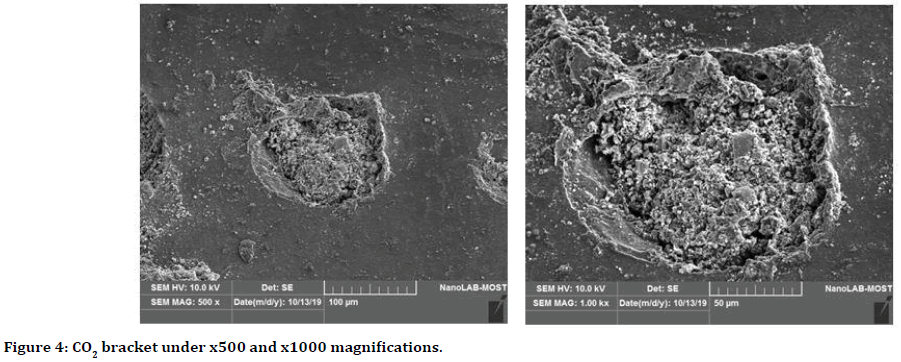

Result: There were highly significant differences in the mean of shear bond strength values among all groups using ANOVA F-test; furthermore, the mean shear bond strength of new brackets had the highest mean value of 22.899 Mpa, followed by Er,Cr:YSGG laser group 20.288 Mpa, then sandblasted group of 11.415 Mpa, while CO2 laser group had the lowest mean shear bond strength value of 2.994 Mpa; furthermore, the results showed significant difference in adhesive remnant index (ARI). Scanning electronic microscope photographs of ceramic brackets processed by sandblasting showed that all the adhesive was removed from the bracket's base, but destroyed the bracket's base as micro retentive structures was smoothed, in Er,Cr:YGSS group, a little adhesive remnants were observed underneath the meshwork and maintained the integrity of the micro structure of the bracket's base, while the brackets that reconditioned by CO2 laser revealed a considerable amount of residual adhesive on the overall bracket's base and in the hollows of the micro structure, while its structure was kept unchanged.

Conclusion: all reconditioning methods would result in clinically acceptable shear bond strength, except CO2 laser method. The Er,Cr:YGSS recycling method can effectively remove the adhesive from the bases of ceramic brackets without damaging them; thus, this method may be preferred over other recycling methods.

Keywords

Recycling, Sandblasting, ErCr: YSGG laser, CO2 laser, Shear bond strength, SEM, Ceramic brackets

Introduction

Fixed orthodontic treatment depends on an effective optimum bond between enamel surfaces and brackets. Failure of bonding procedure is a common occurrence during orthodontic treatment, with reports varying between 3.5% and 23% [1-4]. Eminkahyagil et al. reported that one of every five brackets was debonded during orthodontic treatment [4]. Bond failure may result from sudden force applied by patients to the attachments or due to poor bonding technique [5]. Bond failure is also influenced by other factors such as: bracket type and base design, tooth type and occlusal forces [6]. Additionally, improper bracket placement may necessitate bracket repositioning [7]. Debonding of brackets during treatment is an annoying for both, the clinician and the patient and results in an additional costs and time during treatment [8]. Rebonding of a dislodge/debonded brackets is considered as an economic saving option which could be done using of in-office methods or by commercial recycling. However, due to time consuming process of commercial recycling, inoffice recycling is a preferred option [9]. The SBS of a recycled bracket is affected by many factors including: microscopic damage to the base of the bracket, bracket's base design and amount of remaining adhesive on the bracket base [10] as well as the method used for adhesive removal [11]. Removing the adhesive from a bracket base is conventionally done by means of green stones [11] gas torch [12] and sandblasting [13]. Recycling of bracket by Laser has been discussed in limited number of researches. In recent years, there has been an increasing interest in laser application in dentistry. The first laser introduced to dentistry was Nd:YAG laser. In 1997 Er:YAG laser was approved for dental hard tissues application. Orthodontic applications of lasers have been reported in literature as enamel etching [14], adhesive removal from debonded brackets, pain relief, and acceleration of orthodontic tooth movement [15]. The objective of the present study was to determine the effects of different recycling methods on SBS of rebounded brackets and morphological changes of the brackets' bases after recycling.

Materials and Methods

Teeth

A total of eighty-four extracted human upper first premolars, stored in a solution of 0.1% (weight/volume) thymol. The inclusion criteria for teeth selection were intact buccal enamel, no caries, no cracks, teeth not subject to any chemical agents (such as hydrogen peroxide) and free of hypoplastic area. The teeth were divided into two groups, first group included thirty-six teeth; which were used for preparation of debonded brackets (for recycling), while the second group included forty-eight teeth (for shear bond strength); which were randomly divided into four groups (12 teeth per group) and embedded into a cold-cure acrylic blocks prior to bonding, with coding of the acrylic blocks for randomization.

Brackets

Forty-eight Damon® Clear™ (Ormco Company, California, USA) upper premolar completely aesthetic ceramic passive self-ligation brackets, were used in this study. The base of the brackets had mechanical interlocking pads and slot dimensions are 0.022 × 0.028 of an inch and the base area of the brackets was 10.45 mm2.

Sample preparation and recycling procedure

Debonded brackets were made according to Chung et al. [14], by bonding thirty-six mechanically retentive self-ligating ceramic brackets with Transbond XT (3M Unitek, USA) to unetched and slightly wet tooth surfaces, after removing excess bonding material by a probe, light-cure was applied to the brackets for 20 seconds [16]. Then by using a tweezer, the brackets were easily separated from the tooth surface. The debonded brackets then were randomly divided into three groups (12 brackets per group) according to recycling procedure:

Recycling by sandblasting: The previously debonded ceramic brackets were sandblasted via Micro-etcher (Danville, Carlsbad, CA, USA) at 65 psi for 20 to 30 seconds with 50 μm aluminum oxide abrasive powder, maintaining a 5 mm distance between the ceramic bracket base and the hand piece head, and sandblasting until the adhesive was not visible to the naked eye, then each sandblasted bracket base was rinsed with water for 5 seconds and dried with an air spray [13].

Recycling by Er,Cr: YSGG laser: The previously debonded ceramic brackets were processed by Er,Cr:YSGG laser device (Waterlase, Biolase Technology, Irvine, CA, USA), emitting a wavelength of 2,780 nm. The laser beam was irradiated in a noncontact, focused mode, using 55% water and 65 % air spray. The pulse duration and the pulse repetition rate of the device were constant at 140 μs and 20 Hz, respectively. The output power was set manually at 3.5W. The bracket base was held perpendicular to laser hand peace tip, at a distance of approximately 1-2 mm [17].

Recycling by CO2 laser: The previously debonded ceramic brackets were processed with CO2 laser (Guro-3Dong, Guro-Gu, Seoul, Korea) at wavelength of 10,600 nm operated at pulse mode with output power of 5 W, repeating time of 100 MS and pulse duration of 50 MS with spot size of 0.1 mm. The laser device tip was held at 2–3 mm distance and irradiation was performed for 1.5 min [18].

Rebonding procedure

The teeth in the second group were etched with 37% phosphoric acid for 30 seconds, then washed for 20 seconds, and drying for 10 seconds [19-21]. After etching, the bracket (from 3 experimental groups plus 12 new brackets "the control") bases were coated with a thin uniform coat of Transbond XT primer (3M Unitek, USA), the brackets were placed on the tooth with a constant force at the ideal occluso-gingival and mesio-distal position, excess adhesive composite was removed with an explorer. The adhesive resin was polymerized for 20 seconds [21] with LED dental curing light (Woodpecker, I-plus, Hong Kong, China).

Thermal-cycling procedure

After bonding, the teeth were stored in a normal saline at 37°C for 24 hours, to allow complete polymerization of the bonding material, then thermocycling in deionized water baths was performed between 50°C and 550°C for 500 cycles, following the recommendation of the ISO/TR 11405: 1994, the exposure to each bath was 30 seconds, and the transfer time between the two baths was 5-10 seconds [22,23].

Shear bond strength test

Shear test was performed using a Tinius-Olsen Universal testing machine (H50KT, England) with a 5 KN load cell and a crosshead speed of 1 mm/minute [23,24], and a custom made chisel rod (that was fitted inside the upper arm of the testing machine) was used to apply an occlusogingival load at bracket-tooth interface, while the specimen was secured in the lower jaw of the testing machine. The debonding forces were recorded until bond failure occurred. The force were measured in Newton (N) and then converted to Megapascal by dividing the force on the surface area of bracket base (10.45 mm2).

Scanning Electron Microscope examination

One new bracket and one recycled bracket from each of the 3 experimental groups were observed under a scanning electronic microscope [16.17]. SEM (VEGA, TESCAN) at x500 and x1000 magnification.

Adhesive remnant index

The debonded brackets and the enamel surface of each tooth were inspected under a stereomicroscope (Hamilton, Italy) at x10 magnification to determine the dominant site of bond failure. The site of bond failure was scored according to Wang et al. as followed:

Score I: Adhesive failure occurred between the bracket base and the adhesive.

Score II: Cohesive failure within the adhesive itself, with some of the adhesive remained on the tooth surface and some remained on the bracket base.

Score III: The failure was between the adhesive and the enamel.

Score IV: Enamel detachment.

Results

Table 1 showed the mean shear bond strength (SBS), standard deviation (S.D.), minimum (Min.), and maximum (Max.) values of all groups. The highest mean shear bond strength value was in the control group (22.899 ± 9.330 MPa), followed by Er,Cr:YSGG laser group ( 20.288 ± 5.563 MPa), then the sandblasted group showed the third place (11.415 ± 2.818 MPa, while CO2 group had the lowest mean shear bond strength value (2.994 ± 0.719 MPa).

| Groups | Mean | S.D. | S.E. | Min. | Max. |

|---|---|---|---|---|---|

| Control | 22.899 | 9.33 | 2.693 | 10.05 | 36.52 |

| Sandblast | 11.415 | 2.818 | 0.814 | 7.9 | 15.95 |

| Er,Cr:YSGG | 20.288 | 5.563 | 1.606 | 9.88 | 27.27 |

| CO2 | 2.994 | 0.719 | 0.208 | 1.87 | 4.01 |

Table 1: Descriptive statistics of the shear bond strength (MPa) for different groups.

As can be seen from Table 2, Post hoc Tukey's HSD test showed that there were high significant differences between the control and sandblasted groups, and between the control and CO2 laser groups, while there was no significant difference between the control and Er,Cr:YSGG groups, also there were high significant differences between sandblasted and Er,Cr:YSGG and the CO2 groups, there was also a high significant differences between Er,Cr:YSGG and CO2 groups.

| Groups | Mean Difference | p-value | |

|---|---|---|---|

| Control | Sandblast | 11.484 | 0.000 (HS) |

| Er,Cr:YSGG | 2.612 | 0.717 | |

| CO2 | 19.905 | 0.000 (HS) | |

| Sandblast | Er,Cr:YSGG | -8.873 | 0.001 (HS) |

| CO2 | 8.421 | 0.001 (HS) | |

| Er,Cr:YGSS | CO2 | 17.293 | 0.000 (HS) |

Table 2: Post hoc Tukey's HSD test for multiple comparisons.

Table 3 showed the frequencies and percentages of scores of the ARI for all groups. Score I of the ARI was the highest occurrence among the other scores. The CO2 group had the highest percentage (100%) in regard to the score I, followed by sandblasted group (58.333 %), then Er,Cr:YSGG group (16.667 %), while the control group had the lowest percentage of score I. The second highest score occurrence was score III, the control group had the highest percentage (58.333%), then Er,Cr:YSGG group (50%). Score II had 25% of occurrence distributed mostly in sandblasted group (41.667%), then Er,Cr:YSGG with percentage of occurrence 33.333%, whereas score IV was available only in one group (16.667%) which was the control group.

| Groups | ARI scores | |||||

|---|---|---|---|---|---|---|

| I | II | III | IV | Total | ||

| Control | N | 1 | 2 | 7 | 2 | 12 |

| % | 8.333 | 16.667 | 58.333 | 16.667 | 100 | |

| Sandblast | N | 7 | 5 | 0 | 0 | 12 |

| % | 58.333 | 41.667 | 0 | 0 | 100 | |

| Er,Cr:YSGG | N | 2 | 4 | 6 | 0 | 12 |

| % | 16.667 | 33.333 | 50 | 0 | 100 | |

| CO2 | N | 12 | 0 | 0 | 0 | 12 |

| % | 100 | 0 | 0 | 0 | 100 | |

| Total | N | 22 | 11 | 13 | 2 | 48 |

| % | 45.833 | 22.915 | 27.083 | 4.166 | 100 | |

Table 3: Frequency distribution and percentages of adhesive remnant index in different groups.

Table 4 showed the comparison of ARI among different groups. There was high significant difference among all groups, also there were high significant differences between control group and sandblasted, and CO2 groups, while there was no significant difference between control and Er, Cr:YSGG groups. On the other hand there were a high significant difference between sandblasted group and Er,Cr:YGSS, and CO2 groups. However, there was also a high significant difference between Er,Cr:YSGG and CO2 groups.

| Groups | X2 | Likelihood Ratio | d.f. | p-value |

|---|---|---|---|---|

| Among all groups | 41.005 | 47.324 | 12 | 0 |

| Control-Sandblast | 14.786 | 18.867 | 3 | 0 |

| Control-Er,Cr:YSGG | 3.077 | 3.869 | 3 | 0.276 |

| Control-CO2 | 20.308 | 26.22 | 3 | 0 |

| Sandblast-Er,Cr:YSGG | 8.889 | 11.371 | 2 | 0.003 |

| Sandblast-CO2 | 6.316 | 4.042* | 1 | 0.044 |

| Er,Cr:YSGG-CO2 | 17.143 | 21.788 | 2 | 0 |

Table 4: Comparison of ARI among different groups.

SEM photographs showed differences between the 3 recycling methods. Figure 1 presents typical SEM photographs of bracket bases before initial bonding. The sandblasted brackets photographs showed no remnant adhesives, remarkable micro-smoothening of the bases of the brackets was apparent (Figure 2). The Er,Cr:YSGG laser recycled brackets appeared to have a trace amount of adhesive: However the retentive micro structures were not changed (Figures 3). Although, the CO2 laser recycled brackets showed a considerable amount of adhesive; but maintained the overall micro structure of the bracket's base (Figure 4).

Figure 1. New bracket under x500 and x1000 magnifications.

Figure 2. Sandblasted bracket under x500 and x1000 magnifications.

Figure 3. Er, Cr:YSGG laser bracket under x500 and x1000 Magnifications.

Figure 4. CO2 bracket under x500 and x1000 magnifications.

Discussion

In regard to the increasingly popularity and clinical usage of ceramic self-ligating brackets, a need for an efficient way to recycle these expensive brackets is required. This study was designed to evaluate and compare the shear bond strength of recycled mechanically retentive ceramic brackets via sandblasting, Er,Cr:YAG laser and CO2 laser with new brackets. In this study, the mean SBS in all groups of brackets recycling procedures (except recycled by CO2 group) was higher than the clinically adequate SBS (5.9 to 7.8 MPa) as proposed by Reynolds [25], which means that the recycling methods that were used can resist shear stress to a clinically adequate level.

Sandblasting is commonly used for composite roughening, enamel etching and remove adhesives from the bracket base. In our study, the sandblasted group had a SBS about 11.415 Mpa, which had third place of SBS value after the control and Er,Cr:YSGG laser groups. These observations consistent with those of Amirhossein, et al. [26], this was possibly due to the fact that sandblasting affects the entire base surface and may remove most of the delicate undercuts on the bonding pads of the ceramic brackets, in addition to the fact that sandblasting may not remove the whole adhesive from the bracket's base and some aluminum oxide particles fill the small hallows that acts as a retentive mean for the brackets.

Brackets that were cleaned up with Er,Cr:YSGG laser at 3.5 W yielded shear bond strength values of 20.288 MPa. Although laser-reconditioned brackets experienced some reduction in bond strength compared to that of the new brackets, no statistical difference was found between new (control) and Er,Cr:YSGG group, and therefore brackets cleanup with the Er,Cr:YSGG laser can provide bond strength values that are comparable to that of new attachments and indeed sufficient for clinical applications. The absorption of Er,Cr:YSGG laser would be considerably greater in dental composites than ceramic materials, making it possible to selectively remove adhesive from bases of debonded ceramic brackets. This selective ablation combined with the use of air and water spray during the adhesive removal process prevents from excessive increase in ceramic bracket temperature. These results can be in agreement with those of Ahrari et al. [17] and Amirhossein, et al. [26], also our findings are congruent with the previous studies that found Er,Cr:YSGG laser was efficient in adhesive removal from bases of metallic orthodontic brackets and produced comparable bond strength as with Katsuyuki, et al. [27], or even higher than the new attachments as in Sogra, et al. [18].

Considerable amounts of adhesive remnants were left on the base of CO2 laser-irradiated brackets. SBS of the CO2 laser irradiated brackets fell under optimal range of clinically acceptable bond strength, therefore, results of this study showed that CO2 laser irradiation cannot be considered as an appropriate recycling method, the reason may be due to the remaining of adhesive on bracket base lessened the contact area between the bracket's meshwork and the adhesive, and this lead to a relative decrease in SRS value. As far we know, there was no previous study that evaluate the efficacy of CO2 laser for recycling of ceramic bracket; however our result are consistent with those of Chetan, et al. [28], and Sogra, et al. [18], who used CO2 laser for recycling of metal brackets; but it did not agree with the result of Mojghan, et al. [29] where they found that recycling of metal brackets with CO2 laser had no significant difference from new attachment, this might be attributed to differences in bracket and composite resin types and possibly to differences in bracket materials and laser setting parameters.

SEM demonstrated that new ceramic bracket bases were made up with a well-defined three-dimensional, mechanically retentive pattern with some small hallows, (these work as retentive means for the brackets) and the remaining surface is smooth. Sandblasted ceramic bracket base showed that the general structure of the retentive pattern (undercuts) was distorted and the whole surface was very smooth (mechanical retention was almost lost), while the small hallows seemed to be less in the depth which might be due to the aluminum oxide particles filled these holes or may be these particles remove or scrape the outer layer of the bracket base.

Er,Cr:YSGG irradiated brackets bases appeared to be slightly rougher than the new brackets with a trace amount of adhesive, and the small hallows were not filled with the adhesive; however, the overall shape and microcrystalline structure of three-dimensional, mechanically retentive pattern was not distorted or damaged.

The base of CO2 irradiated bracket exhibited that the retentive pattern was not distorted and the hallows were completely filled with the composite, also the adhesive was on the remaining surface of the bracket base.

There is a belief that rebonding of ceramic or non-damaged metal brackets is cost-saving. On the other hand, clinicians should pay attention to the time spent to clean and prepare the base of brackets for rebonding and the expenditure of additional materials or equipment for these techniques. One criticism of the use of recycled products is that it may produce an increase in the risk of cross-infection. However, any contamination due to the previous use of a recycled appliance is limited as the recycling treatment effectively cleans and decontaminates the appliances [30].

Conclusion

Based on the results of this study the following conclusions were produced:

→ Sandblasting and Er,Cr:YSGG laser were efficient for recondition of mechanically retentive self-ligating ceramic brackets.

→ The means SRS of the sandblasted ceramic brackets, though significantly lower than control group; but exceeded minimum clinically adequate level.

→ The shear bond strength of brackets recycled with Er,Cr:YSGG laser and new brackets were not statistically different.

→ The CO2 laser recycled brackets produced the lowest SRS among all groups which fell under clinically acceptable range.

→ SEM photographs showed that Er,Cr:YSGG laser recycling method was effectively remove the adhesives with no damage to the base of the bracket, unlike the sandblasting method, which cause smoothing and distortion of mechanical retentive pattern of the bracket's base.

→ Under the conditions of this investigation, the results suggest significant difference in ARI, considerably more adhesive remains on the enamel surfaces following bracket recycling.

Conflict of Interest

The authors and planners have disclosed no potential conflicts of interest, financial or otherwise.

References

- Mui B, Rossouw PE, Kulkarni GV. Optimization of a procedure for rebonding dislodged orthodontic brackets. Angle Orthod 1999; 69:276-81.

- Proffit WR, Henry W, Fields JR. Contemporary orthodontics. 3rd Edn St Louis: Mosby 2003; 391–401.

- Zachrisson B. Bonding in orthodontics. In: Graber TM, Vanarsdall RL Edn. Orthodontics: Current principle and techniques. 3rd Edn St Louis: Mosby 2000; 12:557–576.

- Eminkahyagil N, Arman A, Cetinsahin A, et al. Effect of resin removal methods on enamel and shear bond strength of rebonded brackets. Angle Orthod 2006; 76:314-21.

- Lunardi N, Hauber GG, Araujo MMBB, et al. The effect of repeated bracket recycling on the shear bond strength of different orthodontic adhesives. Braz J Oral Sci 2008; 7:1648–1652.

- Pakshir H, Zarif H. Comparison of re bond shear strength and adhesive remnant index between coremax 2 and transbond XT using two different enamel preparation methods. Thesis. Shiraz Dental School, Shiraz University of Medical Sciences.

- Gaffey PG, Major PW, Glover K, et al. Shear/peel bond strength of repositioned ceramic brackets. Angle Orthod 1995; 65:351-358.

- Hobson RS, Hogg SD. Bond strength to surface enamel for different tooth types. Dent Mater 2001; 17:184-189.

- Chetan GB, Muralidhar Reddy Y. Comparative evaluation of four office reconditioning methods for orthodontic stainless steel brackets on shear bond strength: An in vitro study. Annals Essences Dent 2011; 3:6–13.

- Sharma-Sayal SK, Rossouw PE, Kulkarni GV, et al. The influence of orthodontic bracket base design on shear bond strength. Am J Orthod Dentofacial Orthop 2003; 124:74–82.

- Basudan AM, Al-Emran SE. The effect of in-office reconditioning on the morphology of slots and bases of stainless steel brackets and on the shear/peel bond strength. J Orthod 2001; 28:231–236.

- Lew KKK, Djeng SK. Recycling ceramic brackets. J Clin Orthod 1990; 1:44-47.

- Toroglu MS, Yaylali S. Effects of sandblasting and silica coating on the bond strength of rebonded mechanically retentive ceramic brackets. Am J Orthod Dent Orthop 2008; 134. 181-187.

- Chung CH, Friedman SD, Mante FK. Shear bond strength of rebonded mechanically retentive ceramic brackets. Am J Orthod Dentofacial Orthop 2002; 122:282–287.

- Ruhi N, Serpil C. Lasers in orthodontics. Eur J Dent 2013; 7:119-125.

- Sogra Y, Hossein A, Azadeh F, et al. Effect of Er:YAG Laser and Sandblasting in Recycling of Ceramic Brackets. Journal of lasers in medical sciences. 2017; 8:17-21.

- Ahrari F, Fekrazad R, Kalhori KAM. Reconditioning of ceramic orthodontic brackets with an Er,Cr:YSGG laser. Lasers Med Sci. 2012; 28:223-228.

- Sogra Y, Aghili H, Khanpayeh E, et al. Comparison of shear bond strength of rebonded brackets with four methods of adhesive removal. Lasers in medical science. 2013; 29:1563-1568.

- Bishara SE, Oonsombat C, Soliman MM, et al. Comparison of bonding time and shear bond strength between a conventional and a new integrated bonding system. Angle Orthod 2005; 75:237-742.

- Al-Khatieeb MM, Mohammed SA, Attar AMA. Evaluation of a new orthodontic bonding system (Beauty Ortho Bond). J Baghdad College Dent 2015; 27:175-181.

- Martina R, Laino A, Cacciafesta V, et al. Recycling effects on ceramic brackets: A dimensional, weight and shear bond strength analysis. Eur J Orthod 1997; 19:629-36.

- Sokucu O, Siso SH, Nalcaci R, et al. Shear bond strength of orthodontic brackets cured with different light sources under thermocycling. Eur J Dent 2010; 4:257-262.

- Arici S, Arici N. Effects of thermocycling on the bond strength of a resin-modified glass ionomer cement: An in vitro comparative study. Angle Orthod 2003; 73:692-696.

- Amra I, Samsodien G, Shaikh A, et al. Xeno III self-etching adhesive in orthodontic bonding: the next generation. Am J Orthod Dentofacial Orthop 2007; 131:160-165.

- Reynolds IR, Von Fraunhofer JA. Direct bonding of orthodontic attachments to teeth: The relation of adhesive bond strength to gauze mesh size. Br J Orthod 1976; 3:91-95.

- Amirhossein M, Mohammad H, Nasim C, et al. Shear bond strength of rebonded ceramic brackets using four different methods of adhesive removal. J Dent 2018; 15:54-62.

- Katsuyuki I, Toshiya E, Koichi S, et al. Shear bond strength of rebonded brackets after removal of adhesives with Er,Cr:YSGG laser. Odontology 2011; 99:129-34.

- Chetan GB, Reddy M. Comparative evaluation of four office reconditioning methods for orthodontic stainless steel brackets on shear bond strength-an in vitro study. Ann Essences Dent 2011; 3:6-13.

- Mojghan K, Amir M, Maziar M, et al. Comparison of multiple rebond shear strengths of debonded brackets after preparation with sandblasting and CO2 laser. J Dent Res Dent Clin Dent Prospects 2016; 10:148-154.

- Buchman DJL. Effects of recycling on metallic direct bond orthodontic brackets. Am J Orthod 1980; 77:654–668.

Author Info

Zain Alabideen Ahmed1* and Mustafa M Al-Khatieeb2

1Ministry of Iraqi Health, Baghdad, Iraq2Department of Orthodontics, College of Dentistry, University of Baghdad, Iraq

Citation: Zain Alabideen Ahmed, Mustafa M. Al-Khatieeb, Shear Bond Strength of Rebonded Self Ligating Ceramic Brackets after Different Reconditioning Procedures (A comparative an In vitro Study), J Res Med Dent Sci, 2020, 8(1):144-151.

Received: 13-Jan-2020 Accepted: 31-Jan-2020