Research - (2020) Volume 8, Issue 1

Shear Bond Strength of Aged CAD/CAM Ceramic Materials Repaired by Resin Composite In vitro Using Different Repair Adhesives

Rand Mohammed Falah* and Zainab M Abdul Ameer

*Correspondence: Rand Mohammed Falah, Department of Conservative Dentistry College of Dentistry, University of Baghdad, Iraq, Email:

Abstract

Aim of the study: The aim of this study was to evaluate the shear bond strength of three different CAD/CAM ceramic blocks repaired with Nano-hybrid composite resin using three different repair adhesives, and to Compare and determine which bonding systems achieve superior bond strength with each type of ceramic materials tested.

Materials and methods: A total of 72 specimens (10 × 10 × 2 mm) of ceramic mini-blocks will be prepared and divided into three groups (n=24) according to the type of ceramic materials as: Group A: A resin Nano ceramic (VITA Enamic EM-14 2m2HT).

Group B: A feldspar ceramic (Cerec block CPC-14 A2C; Sirona Dental, Germany).

Group C: A lithium disilicate reinforced ceramic (IPS e.max HTA2 CAD; IVOCLAR), then each type was subjected to surface roughness using silicon carbide paper with a grit size of 120 p. Thermo-cycled (500 cycles, 5 °C to 55 °C). Each group was divided into three subgroups treated with three types of repair adhesives as: (1) Ceramic repair kit by Ivoclar vivadent. (2) Scotch bond universal adhesive by 3M ESPE (3) Application of tokuyama universal self-cure bond. All blocks will be repaired using the Nano-hybrid resin composite (Tetric Evo Ceram/A2). The ceramic-composite blocks will then subject to shear bond strength testing machine and the failure mode will be determine with stereomicroscopes. The data were analyzed using Two-way ANOVA and Bonferroni post hoc test (multiple Pairwise comparisons).

Results: The result of this study revealed that for the vita Enamic groups, Ivoclar repair system showed higher bond strength values with a significant difference with Palfique universal bond. In Cerec CPC and IPS e.max CAD, Palfique universal bond showed the highest mean bond strength values than the other repair adhesives.

Conclusion: Palfique universal bond achieved a high bond strength values with each type of ceramic material tested in this study. Type of ceramic materials produces the greatest influence on the bonding strength with a specific type of repair adhesive. Ivoclar ceramic repair system kit worked better with Vita Enamic ceramic. Scotch bond universal adhesive produced best results with IPS e.max CAD. Palfique universal bond bonds with the three types of ceramics equally.

Keywords

Ceramic materials, Universal bond, Bond strength, Palfique bond

Introduction

Applications of esthetic restorations especially the indirect such as crowns, veneers, inlays and onlays has been growing progressively with increasing demand for best esthetic result. Numerous dental restorative materials and methodology have been created to produce the best indirect esthetic restorations [1].

Ceramic materials are susceptible to fractures. It has been shown that breaking point is induced at the occlusal surface for posterior teeth or palatal surface for anterior teeth. The treatment lines of damaged restorations have been reported by Setcos et al.: (1) Do nothing (observation); (2) Remodeling (not to add a new restorative material); (3) Repair (addition of a resin restorative material); and (4) To replace.

The ability to repair dental restorative materials together with its superior physical and mechanical characteristic is crucial for minimally invasive dentistry. It had been found in many previous in vitro studies that repaired restoration have a higher survival rates than replaced restoration. Numerous factors will influence the decision on whether to repair or to replace the failing restoration such as the type and extent of failure, properties of materials and the cost.

Although the size of the cracks and fractures type within the ceramic restoration will determine the treatment type, intraoral adhesive repair procedures can be indicated as the safe removal of damaged ceramic restoration without causing destruction to the underlying tooth is usually not possible [1].

With the developments in computerized dentistry, manufactured ceramic blocks, which are milled with CAD/CAM systems have been, produced [2]. The advantage of this CAD/ CAM system in dental applications empowered the modeling of high-performance materials that cannot be effectively cut to form dental restorations [3].

It had been proven in many previous studies that surface pretreatment (mechanical roughening) must be performed in the repair process for CAD/CAM resin materials in order to generate irregularities on the fractured ceramic surface leading to increase bonded surface area [4-6].

Mechanical pretreatment essentially cleans and increase the surface area, leading to higher bond strength values owing to mechanical retention [7]. A study done by Stawarczyk et al. in 2015 demonstrated that additional conditioning with adhesives is required to attain significant improved adhesion between resin composite and CAD/CAM resin, as micromechanical retention is not sufficient alone due to the standardized polymerization procedure, these resins have barely sufficient carbon-carbon double bonds on the surface to which the resin luting agent can be bonded [8].

Limited information was published about the efficacy of repair adhesive of resin composites to ceramic blocks. This study was carried out with the need of testing the bonding strength of three different CAD/CAM blocks repaired with composite resin using three different repair adhesives.

Materials and Methods

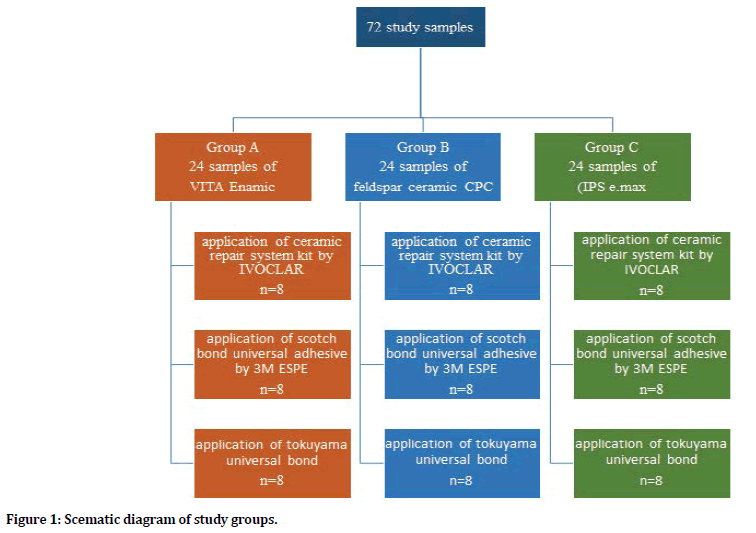

Three different CAD/CAM ceramic materials (VE, Cerec CPC and IPS e.max CAD) were chosen for the study. From every material, 24 samples (10 × 10 × 2 mm) were set up from prefabricated blocks utilizing a low speed cutting device under water cooling. Firing scudual for the IPS e.max CAD and Cerec CPC blocks was done according to manufacturer instruction before surface treatment. A firing procedure was not necessary for hybrid Vita enamic ceramics. Specimens were embedded in acrylic resin blocks (20 × 20 × 15) and then the surface of all the samples have been standardized by using the grinder/polisher machine in which each sample was grinded in two steps; the first step, a silicon carbide paper with a grit size of 400P followed by 600P with rotational speed of 220 RPM under water cooling for 2 min. the specimen then subjected to thermo cycling procedure between 5 °C and 55 °C for 500 cycles with a 30 seconds dwell time. For surface roughness, the surface of all samples have been treated with a sand paper with a grit size of 120P that simulate clinical situation of using 125 μm abrasive particle size diamond burs with high-speed Hand piece in order to increase the bonded surface area. All specimens were cleaned in distilled water for 10 minutes in an ultrasonic cleaner to remove the loose particles of the ceramic materials [6]. Each type of ceramic materials was divided into three subgroups according to type of repair adhesives Figure 1:

Figure 1. Scematic diagram of study groups.

Subgroup 1: Application of ceramic repair system kit (n=8).

Subgroup 2: Application of scotch bond universal adhesive (n=8).

Subgroup 3: Application of tokuyama universal bond (n=8).

After the application of the repair adhesives, the composite resin Tetric EvoCeram filling material (Ivoclar Vivadent, Germany) was packed in single increment using a specially design Teflon mold to hold the composite resin over the ceramic sample that was 6 mm in diameter and 2 mm in height. The material was light cured for 20 seconds with the tip of the light-curing unit placed in an intimate contact with overlying celluloid strips for all samples [9]. After curing, the ceramic-resin composite block was removed from the mold and the adhesive interface was exposed to additional 40 sec of irradiation Figure 2 [10].

Figure 2. Study sample.

All the samples were stored in deionized distilled water within a dark container at a temperature of 37ᵒC before bond strength testing to allow for post-polymerization [1].

Shear bond strength test

SBS test was performed with Laryee universal testing machine (China) using a stainless steel chisel-shaped rod with across head speed 0.5 mm/min [11].

The SBS was obtained from the following equation:

SBS=Force (Newton)/Surface area (mm2)

Surface area=πr

Π=3.14, r=Radius, r=3 mm

Surface area: 3.14 × 32=28.26 mm2

SBS results were statistically analyzed by 2-way ANOVA. Bonferonni test adjustment for multiple comparisons of SBS within subgroups between groups. The statistical tests were performed with special software SPSS Version 21.0. At a level of significance of (0.05). After shear bond testing, the sample and the broken parts were examined under stereomicroscope a 40X magnification to determine the mode of failure.

Results

The result of the 2 way ANOVA showed that the largest effect size on SBS was between the subgroups of group B followed by group C and the least effect size was in group A (Table 1). Bonferonni-test was used as shown in Table 2 to find the subgroups responsible for the difference. Mean bond strength values are presented in Table 3.

| Groups | Sum of Squares | df | Mean Square | F | Sig. | Partial Eta Squared |

|---|---|---|---|---|---|---|

| A | 31.16 | 2 | 1.58 | 3.635 | 0.032 | 0.103 |

| B | 86.631 | 2 | 43.315 | 10.106 | 0 | 0.243 [Large effect] |

| C | 46.37 | 2 | 23.185 | 5.409 | 0.007 | 0.147 |

Table 1: Two-way ANOVA test of SBS mean value between subgroups within groups.

| Groups | (I) Subgroups | (J) Subgroups | Mean Difference (I-J) | Sig. |

|---|---|---|---|---|

| A | A1 | A2 | 2.744 | 0.03 |

| A3 | 0.929 | 1 | ||

| A2 | A3 | -1.815 | 0.253 | |

| B | B1 | B2 | -0.265 | 1 |

| B3 | -4.156 | 0 | ||

| B2 | B3 | -3.891 | 0.001 | |

| C | C1 | C2 | -1.891 | 0.217 |

| C3 | -3.398 | 0.005 | ||

| C2 | C3 | -1.506 | 0.452 |

Table 2: Bonferonni test between subgroups for each group.

| Groups | Subgroups | Mean | ±SD | Minimum | Maximum |

|---|---|---|---|---|---|

| A | A1 | 11.585 | 2.405 | 8.49 | 15.92 |

| A2 | 8.841 | 1.414 | 6.72 | 10.96 | |

| A3 | 10.656 | 3.015 | 6.72 | 14.5 | |

| B | B1 | 6.808 | 1.603 | 3.18 | 8.49 |

| B2 | 7.073 | 2.299 | 4.6 | 10.96 | |

| B3 | 10.964 | 2.081 | 8.13 | 15.21 | |

| C | C1 | 9.249 | 2.317 | 6.79 | 14.15 |

| C2 | 11.14 | 1.501 | 9.55 | 14.5 | |

| C3 | 12.646 | 1.375 | 10.61 | 14.15 |

Table 3: Mean bond strength values for all groups.

From this table we can see for group A (Vita Enamic) there was significant difference only between subgroup A1 (IVOCLAR ceramic repair system kit) and sub group A2 (scotch bond universal). For group B (Cerec CPC) there was a highly significant difference between subgroups B1 (IVOCLAR ceramic repair system kit) and subgroup B3 (Palfique universal bond) and between subgroup B2 (scotch bond universal by 3M) and subgroup B3 (Palfique universal bond).

For group C (IPS e.max CAD) there was only highly significant difference between subgroup C1 (IVOCLAR ceramic repair system kit) and C3 (Palfique universal bond). Two-way analysis of variance was used at level of significance of (0.05) as in Table 4, In order to determine the effect of adhesive systems on SBS between the three types of ceramic materials. There was a highly significant difference among the three types of ceramics when using IVOCLAR ceramic repair system kit and using scotch bond universal adhesive, but there was no significant difference of using the Palfique universal bond for all three ceramic materials.

| Subgroups | Sum of Squares | Df | Mean Square | F | Sig. | Partial Eta Squared |

|---|---|---|---|---|---|---|

| IVOCLAR ceramic repair system kit | 91.313 | 2 | 45.656 | 10.652 | 0 | 0.253 [Large effect] |

| scotch bond universal adhesive | 66.553 | 2 | 33.276 | 7.764 | 0.001 | 0.198 |

| Palfique universal bond | 18.361 | 2 | 9.181 | 2.142 | 0.126 | 0.064 |

Table 4: Two-way test of difference of SBS between groups within subgroups.

Bonferroni test was done for IVOCLAR ceramic repair system kit subgroups among the three ceramic groups and also was done for scotch bond universal adhesive subgroups among the three ceramic groups to determine the level of significance as shown in Table 5.

| Subgroups | (I) Groups | (J) Groups | Mean Difference (I-J) | Sig. |

|---|---|---|---|---|

| IVOCLAR ceramic repair system kit | A | B | 4.778 | 0 |

| C | 2.336 | 0.082 | ||

| B | C | -2.441 | 0.064 | |

| scotch bond universal adhesive | A | B | 1.769 | 0.277 |

| C | -2.299 | 0.09 | ||

| B | C | -4.068 | 0.001 |

Table 5: Bonferonni test adjustment for multiple comparison of SBS within subgroups.

There was only high significant difference between groups A and B when using IVOCLAR ceramic repair system kit and no significant difference found among the other groups.

For scotch bond universal adhesive subgroups, there was a high significant difference for SBS between groups B and C with no significant difference found among the other groups.

There was no adhesive failure within the vita enamic and Cerec CPC groups; no cohesive failure was developed within the e-max group. The percentage of mixed failure within the study samples was found to be 59.7% while 27.7% accounted for cohesive failure and only 12.5% accounted for adhesive failure.

Discussion

During clinical service many factors may cause fracture of ceramic restorations such as trauma, attrition, abrasion, etc. As a result of the method of the ceramic processing, the addition of new porcelain material to an existing intra-oral fractured restoration wouldn’t be possible [5]. In consequence, intraoral, repair can be regarded as a localized emergency treatment for fracture restoration [12]. In addition, it represents a possible alternative for replacement of a fractured, all, ceramic, restoration as the removal is not easy and mostly costly for these restorations [13].

The base design of the, present study was to simulate as much as, possible the clinical situation in order to give a simple clinical circumstance so as to give a basic clinical direction for repair done by the practitioners, as intra-oral air abrasion by particulate abrasives and proprietary silica coating devices, or chemicals such as hydrofluoric and hydrochloric acids may not be available. Thus, this study was planned to detect the intra-oral reparability of three different CAD/CAM ceramic materials as simple alternative to the extra-oral repair of fractured ceramic restoration by using Nanohybrid resin composite (Tetric EvoCeram /A2) with three different intermediate adhesives layer used for repair.

A nano-hybrid resin composite (Tetric EvoCeram /A2) had been selected for the repair. The nanohybrid composite resin was selected along with the ability of the material to be used for intraoral repairs of fractured ceramic restorations in addition for anterior and posterior direct restorations.

Evaluation of the adhesion between ceramic and composite materials done by using the shear bond strength test. Although it has been reported in many previous studies that using shear bond strength for measuring bond strength considered as a less reliable test than the microtensile bond strength as it leads to non-uniform distribution of the stresses at the adhesive area [14], but the forces directed to the repair area are mainly in the shear manner, moreover shear test require simple sample preparation and easy test protocol [5].

Results of this study led to the rejection of the null hypothesis: no difference in the shear bond strength between the three adhesive repair systems tested in this study when bonded to three different aged CAD/CAM ceramic materials.

For the Vita Enamic group (group A) the results of this study revealed that there is no statistically significant difference between the three adhesive tested with only a significant difference found between the Ivoclar ceramic repair system kit and the scotch bond universal adhesive, with Ivoclar kit showed slightly higher bond strength value, this means that the vita enamic capable of bonding with the three types of adhesive tested each with different type of monomer with the Ivoclar repair system kit perform slightly better. This could be explained that the Zirconium oxide within the Vita enamic ceramic materials can react with phosphate ester monomers, which is why MDP-containing primers or resin can improve bonding [15]. Previous studies have reported that the shear bond strength between resin luting agents and zirconium oxide ceramics increased by the addition of an MDP-containing bonding/saline agent mixture [16, 17].

the priming agent Monobond Plus (part of the Ivoclar repair kit), comprises (3-MPS) monomer, sulphide methacrylate and methacrylated phosphoric acid ester, lead to the highest bond strengths, and when the two phosphatemonomer- based primers used in this study were compared, Monobond Plus showed statistically significantly higher bond strength than scotch bond universal adhesive. This may be related to the composition of Monobond Plus, as it contains both an MDP monomer and a saline monomer 3-MPS [18]. In addition the presence of MDP in scotch bond universal is slightly more hydrophilic led to less wetting of the resin matrix of the hybrid ceramic so decrease the bond strength [19].

For the Cerec blocs CPC (group B) there was a highly significant difference between Ivoclar ceramic repair system kit and Palfique universal bond and between scotch bond universal and Palfique universal bond, with the Palfique universal bond produce higher bond strength values than the two others and there was no significant difference found between the ivoclar repair kit and the scotch bond universal, both of them produce low bond strength values.

This could be explained by the chemical composition of the Cerec CPC ceramic, it lack zirconium oxides so both Phosphate-monomercontaining agents (Ivoclar repair system kit and the scotch bond universal) couldn’t achieve a high bond strength values as the Palfique universal bond which contains a new 3D-SR monomer that have several functional groups that can interact with calcium and polymerizing groups per molecule. For the IPS e.max CAD (group C) the highest values for the mean SBS were obtained within this type of material with the three types of the adhesive tested, this may be related to the ability of lithium disilicate ceramic blocks to respond to surface treatment much better than the other two ceramics, this result is in accordance with the result of [1] who concluded the surface roughness increase bond strength for the lithium disilicate, didn’t increase bond strength for the feldspathic and reduced bond strength for hybrid ceramic. No significant difference had been found between scotch bond universal and Ivoclar repair system kit with a slight higher bond strength with the scotch bond as it contain HEMA as an organic monomer while the heliobond contain Bis-GMA as an organic monomer, both responsible for the formation of the bonding layer, in addition the HEMA is a low molecular weight monomer, which is characterized by its hydrophilic properties and is an essential component of most adhesive systems [20]. No significant difference had been found between Palfique universal bond and the scotch bond universal as both type contain the organic monomer HEMA with slightly higher bond strength with the Palfique universal bond since it contain two additional monomer Bis-GMA and TEGDMA that may increase the bond strength. A high significant difference founded between the Ivoclar repair system kit and the Palfique universal bond with higher bond strength values obtained with the Palfique universal bond since it contain three types of organic monomers (HEMA, Bis-GMA and TEGDMA) while the Ivoclar repair system kit based on only Bis-GMA as an organic monomer. Regarding the performance of the repair adhesive tested in this study with each ceramic, it was clear that the type of the ceramic materials produce different bond strength with the same adhesive tested.

The results of this study indicate that the bonding strength was lower (range between 6.808 and 12.646 MPa) when compared with other studies that utilized μTBS. A systematic review remarked that expansion in the bonded area is associated with reduced bonding strength values. Indeed, the results of “macro” tests can range between 5.6 and 11.5 MPa, in consistence with the results [21], Nevertheless, comparison of results from different testing methods would not be appropriate [22].

Conclusions

Within the limitation of this in vitro study, the following conclusion could be gained:

1. For the vita enamic materials, the ivoclar ceramic repair system kit produced the higher bond strength value than the two others.

2. For the Cerec CPC, Palfique universal bond produced the higher bond strength value.

3. For the IPS e.max CAD, Palfique universal bond and scotch bond universal act better than the ivoclar ceramic repair system kit.

4. Within a specific type of repair adhesive, the type of ceramic materials produced the great influence on the bonding strength:

I. Ivoclar ceramic repair system kit worked best with vita enamic type of material.

II. Scotch bond universal adhesive bonded to the IPS e.max CAD better when compared with the other adhesives.

III. Palfique universal bond bonded equally with the three types of ceramic materials.

Type of the functional monomers were responsible for the differences in the shear bond strength value among the groups.

References

- Duzyol M, Sagsoz O, Polat Sagsoz N, et al. The effect of surface treatments on the bond strength between CAD/CAM blocks and composite resin. J Prosthodont 2016; 25:466-471.

- Conrad HJ, Seong WJ, Pesun IJ. Current ceramic materials and systems with clinical recommendations: A systematic review. J Prosthet Dent 2007; 98:389-404.

- Jedynakiewicz N, Martin N. CEREC: Science, research, and clinical application. Compend Contin Educ Dent 2001; 22:7-13.

- Tinastepe N, Turkes E, Kazazoglu E. Comparative approach to analyse the effects of different surface treatments on CAD/CAM resin nanoceramics–resin composite repair bond strength. Biotech Biotech Equip 2018; 32:142-149.

- Güngör MB, Nemli SK, Bal BT, et al. Effect of surface treatments on shear bond strength of resin composite bonded to CAD/CAM resin-ceramic hybrid materials. J Adv Prosthodont 2016; 8:259-266.

- Arpa C, Laura C, María Victoria F, et al., Repair bond strength and nanoleakage of artificially aged CAD-CAM composite resin. J Prosthet Dent 2019; 121:523-530.

- Naves LZ, Soares CJ, Moraes RR, et al. Surface/interface morphology and bond strength to glass ceramic etched for different periods. Oper Dent 2010; 35:420-427.

- Stawarczyk B, Krawczuk A, Ilie N. Tensile bond strength of resin composite repair in vitro using different surface preparation conditionings to an aged CAD/CAM resin nanoceramic. Clin Oral Invest 2015; 19:299-308.

- Stanislawczuk R, Amaral RC, Zander-Grande C, et al. Chlorhexidine-containing acid conditioner preserves the longevity of resin-dentin bonds. Oper Dent 2009; 34:481-490.

- Elsaka SE. Repair bond strength of resin composite to a novel CAD/CAM hybrid ceramic using different repair systems. Dent Mater J 2015; 34:161-167.

- Saleh HA, Baban LM. Evaluation of the effect of intermediate agents on the shear bond strength of repaired aged silorane resin composite. J Baghdad College Dent 2012; 24:8-13.

- Bottino MA, Campos F, Ramos NC, et al., Inlays made from a hybrid material: Adaptation and bond strengths. Oper Dent 2015; 40:83-91.

- Sjögren G, Molin M, van Dijken JW. A 10-year prospective evaluation of CAD/CAM-manufactured (Cerec) ceramic inlays cemented with a chemically cured or dual-cured resin composite. Int J Prosthodont 2004; 17:241-246.

- Della Bona A, Van Noort R. Shear vs. tensile bond strength of resin composite bonded to ceramic. J Dent Res 1995; 74:1591-1596.

- Chen C, Kleverlaan CJ, Feilzer AJ. Effect of an experimental zirconia–silica coating technique on micro tensile bond strength of zirconia in different priming conditions. Dent Mater 2012; 28:127-134.

- Nothdurft F, Motter P, Pospiech P. Effect of surface treatment on the initial bond strength of different luting cements to zirconium oxide ceramic. Clin Oral Inv 2009; 13:229.

- Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: A review of the literature. J Prosth Dent 2003; 89:268-274.

- Tanış MÇ, Akay C, Karakış D. Resin cementation of zirconia ceramics with different bonding agents. Biotechnol Biotechnol Equip 2015; 29:363-367.

- Schwenter J, Schmidli F, Weiger R, et al. Adhesive bonding to polymer infiltrated ceramic. Dent Mater J 2016; 35:796-802.

- Nassif M, El Askary F. Nanotechnology and nanoparticles in contemporary dental adhesives. Nanobiomater Clin Dent 2019; 163-198.

- Braga RR, Meira JB, Boaro LC, et al. Adhesion to tooth structure: A critical review of “macro” test methods. Dent Mater 2010; 26:38-49.

- Hu M, Weiger R, Fischer J. Comparison of two test designs for evaluating the shear bond strength of resin composite cements. Dent Mater 2016; 32:223-232.

Author Info

Rand Mohammed Falah* and Zainab M Abdul Ameer

Department of Conservative Dentistry College of Dentistry, University of Baghdad, IraqCitation: Rand Mohammed Falah, Zainab M Abdul Ameer, Shear Bond Strength of Aged CAD/CAM Ceramic Materials Repaired by Resin Composite In vitro Using Different Repair Adhesives, J Res Med Dent Sci, 2020, 8(1): 61-67.

Received: 30-Dec-2019 Accepted: 20-Jan-2020