Review Article - (2023) Volume 11, Issue 1

Mode of Adhesion between Soft Reline Material and Denture Base Material

Rawaa Zaher Hassan Zwain1*, Anwar Hussein Jawad2, Rusul Subhi Hassan3 and Dunya Malhan Hanweet4

*Correspondence: Rawaa Zaher Hassan Zwain, Department of Prosthetic, College of Dentistry, University of Kufa, Iraq, Email:

Abstract

The aim of study: Evaluate the effect of different surface treatments on Shear Bond Strength (SBS) of different reline materials to highly acrylic denture base resin. Relining the ill-fitting removable dentures improves their stability, support and retention. The search on the mode of adhesion between relines material and denture base material to reach the optimum result of the bond strength to optimize the benefit from the relining.

Conclusion: The use of monomer before the soft liners creates a chemical connection between the poly methyl methacrylate resilient liner and the poly methyl methacrylate denture base. Before applying robust liner to heat cured acrylic denture (acrylic or silicone).

Keywords

Adhesion, Soft relines, Denture, Shear bond strength, Ill-fitting

Introduction

The intaglio surface of a detachable prosthesis may need relining due to tissue changes. It is simpler, quicker and more convenient than a laboratory relining method [1]. To adjust the ill-fitting prosthesis to the remaining ridge, it has been employed to directly mimic the morphology of oral soft tissues [2]. However, bad smell, monomer irritation of oral soft tissue, polymerization heat production and weak chemical interaction between reline material and denture base resin are clinical concerns. Many authors have investigated this chemical bond, demonstrating that adhesive failure and poor bond strength are prevalent concerns.

These resins include methacrylate monomers with higher molecular weights than methyl methacrylate. This may affect relining resin monomer penetration into denture base resin, reducing the strength of the two material connection [3,4]. The new highly cross linked denture base resin may reduce the supply of monomers needed to build the interwoven polymer between denture base resins and reline resin, weakening the bond.

Materials and Methods

Hard reline materials

• Mouth cured hard reline material.

• Light activated resin.

• Chemically activated acrylic resin.

• Processed hard denture liners.

Heat activated resin

Include:

Water bath: The application of thermal energy leads to the decomposition of the initiator and the production of free radicals, which will subsequently initiate polymerization. The polymerization should occur at temperatures between (74°C-77°C) to prevent war page [5].

Craig and powers stated that acrylic resin may be polymerized by either one of the two acceptable methods [6].

• The long polymerization cycle involves a constant temperature water bath at 74°C for 8 hours or longer (overnight curing).

• The short polymerization cycle involves processing the resin at 74°C for 1.5 hours and then at 100°C for 30 minutes.

However, in relining accomplished using resin that is activated by heat, significant heat may be generated and distortion of the existing denture base is more likely [7].

Microwave: The major advantages of microwave heating over conventional heating are that the inside and outside of substances are almost equally heated and the temperature rises rapidly [8].

The use of microwave irradiation produced high frequency motion of monomer molecules; increases the internal heat and consequently results in greater conversion of monomer into polymer therefore; less residual monomer amount is one of the advantages of microwave polymerization, which lead to more reduction of the toxic effect of acrylic resin [9-11].

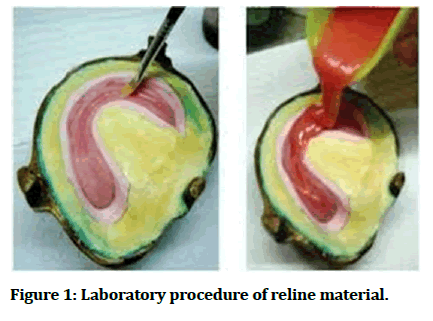

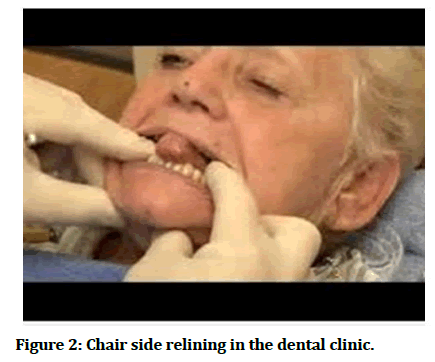

Therefore, the choice of a suitable microwave power and polymerization time is important to reduce porosity to a minimum level and increase the domain size and volume of the rubber phase (Figures 1 and 2).

Figure 1: Laboratory procedure of reline material.

Figure 2: Chair side relining in the dental clinic.

Types of lining materials according to the composition:

• Acrylic based denture soft liners.

• Plasticized acrylic resin soft liner.

• Chemically activated soft liners.

• Heat activated soft liners.

• Silicon soft denture liners.

Chair side versus laboratory processed reline: Direct relining of dentures made with hard chair side reline resins is faster than laboratory processed reline systems and the patient is not without the prosthesis for the time necessary to perform the laboratory procedures. However, a weak bond between the autos polymerizing acrylic relines resins and the denture base material has been observed. This study evaluated the effect of six different surface treatments on the bond strength between a hard chair side reline acrylic resin and a heat cured acrylic resin. Specimens of the heat cured acrylic resin were divided into seven groups.

One of these groups remained intact. In the other groups, a 10 mm square section was removed from the center of each specimen.

The bonding surfaces were then treated with:

• Methyl methacrylate monomer.

• Isobutyl methacrylate monomer.

• Chloroform.

• Acetone.

• Experimental adhesive.

• No surface treatment control group.

Koo liner acrylic resin was packed into the square sections and polymerized. The bonding strength was evaluated by a three point loading test. The results were submitted to one way Analysis of Variance (ANOVA) followed by a Tukey multiple range test at a 5% level of significance. No significant difference was found between the surface treatment with lucitone 550 monomer or chloroform, but both were stronger than the majority of the other groups. The bond strength provided by all the surface treatments was lower than that of the intact heat cured resin (Figure 3) [12,13].

Figure 3:Complete denture.

Results

Principle of adhesion

Adhesive joint: Forming an adhesive junction is called adhesion. The original substrate is known as the adherent, whereas the substance that forms the interface is known as the adhesive. When two substrates are connected, the adhesive creates two interfaces.

In dentistry, the adhesive layer is made up of multiple phases, each with its own components. These are termed bonding agents.

Type of adhesive materials

Dow corning 2014 has non-corrosive silicone materials for electronic sealing, bonding and attaching.

These adhesives have three cure kinds:

• Moisture cures are intended for room temperature processing.

• This kind allows speedy room temperature and deep section curing.

• Heat cure is used for quick processing. All convert to tough, low stress elastomers.

Most will acquire excellent primer less adhesion to ceramics, reactive metals and filled plastics. New adhesives from Dow corning help automotive suppliers save costs 2013 Dow corning (Tables 1-3).

| One part moisture cure RTV overview |

|---|

| Type: Non-corrosive, one part moisture curing RTV silicone elastomers. |

| Physical form: Non-flowing and flow able options; cures to flexible elastomer. |

| Special properties: Room temperature cure; opaque and translucent options; resists humidity and other harsh environments; good dielectric properties; good adhesion to a variety of common substrates; low stress. |

| Potential uses: Sealing modules and housings; gasketing. |

Table 1: One part moisture cure RTV overview.

| Two part room temperature condensation cure overview |

|---|

| Type: Two part RTV silicone elastomers. |

| Physical form: Non-flowing; cures to flexible elastomer. |

| Special properties: Rapid cure and green strength at room temperature; deep section cure; resists humidity and other harsh environments; good dielectric properties; self-priming adhesion; low stress. |

| Potential uses: Lid and housing seals; gasketing. |

Table 2: Two part room temperature condensation cure overview.

| Heat cure overview |

|---|

| Type: One and two part silicone elastomers. |

| Physical form: Non flowing and flow-able options; cures to flexible elastomer. |

| Special properties: Fast thermal cure; resists humidity and other harsh environments; good dielectric properties; self-priming adhesion; low stress. |

| Potential uses: Lid and housing seals; gasketing. |

Table 3: Heat cure overview.

Mode of adhesion

• Surface roughness.

• Solvents (monomer).

The methyl methacrylate and ethyl methacrylate monomers in robust liners are structurally similar. They may mix during polymerization to form a copolymer. The soft poly ethyl methacrylate liner and the hard poly methyl methacrylate denture base may chemically mix when the monomer is applied to the denture base before the soft liner. Silicone, on the other hand, has a different chemistry than poly ethyl methacrylate acrylic denture base resin. They have no chemical connection. The primer acts as an adhesive between the two components in the poly methyl methacrylate/silicon bond [12].

Adhesion versus bond strength

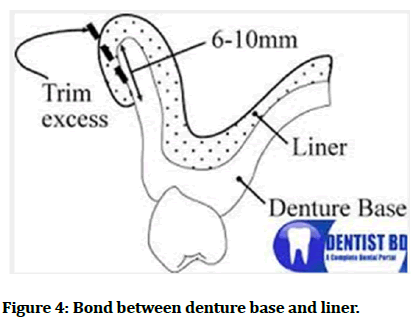

Dentistry relies on the process of forming a joint and the resistance of the joint to failure. The science of adhesion studies the formation of an adhesive joint. There is a specific energy of adhesion determined by the chemical, physical and mechanical attributes of the substrate and adhesive. Once formed, the joint's resistance to failure depends on the extent of defects along the interface that allow cracks to form, grow and rupture the joint. Failure processes depend on the bulk properties of the adhered and adhesive, the environment of the bond and time. Craig and gibbons, stated that tensile strength of resilient denture lining material increased after storage in water [14]. Also, Emmer, et al. thought that the prolonged exposure to water significantly increases the failure strength [15] (Figure 4).

Figure 4: Bond between denture base and liner.

Interface formation of adhesion

Formation of an optimally bonded interface requires that:

• The surface of the substrate is clean.

• The adhesive wet the substrate well, have a low contact angle and spread on to the surface.

• Adaptation to the substrate produce intimate approximation of the materials without entrapped air or other intervening materials.

• The interface include the sufficient physical, chemical and mechanical strength to resist intraoral forces of de bonding.

• The adhesive be well cured under the conditions recommended for use [16].

Discussion

The effect of Er: Rasheed and Al-nakkash studied YAG laser surface treatment on shear bond strength and certain mechanical properties of heat cured acrylic denture base material bonded to chair side soft lining material [17]. Transversal and impact strength of heat cured acrylic resin are unaffected by Er: YAG laser. Neither Er: YAG laser surface treatment for 14 days storage in prepared artificial saliva affected the shear bond strength of chair side silicone based soft lining material to heat cured acrylic denture base material.

Another research by Wodzimierz, et al. indicated that all tested materials had satisfactory adhesion qualities to acrylic resin [18]. A soft line 30 offers the best tensile and shear bond strengths according to testing.

The findings demonstrated considerable variations in the bonding of liners to the denture base and light cure systems displayed the maximum amount of force required for failure. Low bond strength was detected when the soft liner's adhesion or cohesive strength was weak, leading to pure adhesive or cohesive failure. High strains caused the breakdown of both adhesive and cohesive bonding. Intermediate examples showed mixed adhesive and cohesive failures (mixed mode).

Hachmi evaluated the shear bond strength of silicon based soft liners to acrylic resin denture bases using various polymerization techniques and storage times in distilled water, concluding that UFI gel P out performed visible light cure acrylic resin in terms of shear bond strength [19]. Water storage for 1 month or 3 months reduces the shear bond strength of UFI gel P soft liner to a heat cured or UV cured denture foundation.

A 2012 research by Abdul Sattar and Abdul Alfattah discovered that a glass fiber surface treatment might increase the bonding between the acrylic surface and the soft liner.

Karin, et al. the bond strength of hard chair side reline resins to a quick polymerizing denture base resin was evaluated before and after heat cycling.

Salloum investigated the shear bond strength of three silicone lining materials attached to heat cured denture resin. The study found no statistically significant differences amongst the silicone materials investigated. Process molloplast-B with unpolymerized PMMA to increase bond strengths.

Mutluay evaluated the binding strength of soft relining materials to denture base polymers.

Conclusion

Soft denture liners must fit nicely to operate effectively and last long. Two times as much adhesiveness as a smooth surface. The surface sandblasting of PMMA/ PEMA/silicone specimens reduced their peel strengths. The poly methyl methacrylate strong liner and the poly methyl methacrylate denture base are connected chemically by a monomer before the soft liners. Because silicone has no chemical bond, the primer holds it together. Lasering heat cured acrylic dentures boost shear bond strength and decrease wear. The dry denture foundation resin outperformed desiccated and water saturated denture base resins. It should be able to sustain intraoral force deboning. Glass fiber surface treatment enhances acrylic denture base and soft liner adherence.

References

- Arima T, Murata H, Hamada T. Analysis of composition and structure of hard auto polymerizing reline resins. J Oral Rehabil 1996; 23:346-352. [Crossref][Googlescholar][Indexed]

- Haywood J, Basker RM, Watson CJ, et al. A comparison of three hard chair side denture reline materials. Part I clinical evaluation. Eur J Prosthodont Restor Dent 2003; 11:157-163. [Googlescholar][Indexed]

- Yutaka T, John Chai J. Shear bond strength of denture reline polymers to denture base polymers. Int J Prosthodont 2001; 14. [Googlescholar][Indexed]

- Giampaolo ET, Jorge JH, Machado AL, et al. Effect of thermal cycling on micro leakage between hard chair side relines and denture base acrylic resins. Gerodontol 2011; 28:121-126. [Crossref][Googlescholar][Indexed]

- Craig RG, Powers JM. Restorative dental materials. 11th edition, St Louis: Mosby, 2002; 348-370.

- Craigs RG, Powers JM. Restorative dental materials. 11th edition, St. Louis Mosby Co, 2002; 21:636-689.

- Anusavice KJ. Dental casting alloys. Phillip's Sci Dent Materials 1996; 423-459.

- Lai CP, Tsai MH, Chen M, et al. Morphology and properties of denture acrylic resins cured by microwave energy and conventional water bath. Dent Mater 2004; 20:133-141. [Crossref][Googlescholar][Indexed]

- Jorge, JH, Giampaolo ET, Machado AL, et al. Cytotoxicity of denture base acrylic resins: A literature review. J Prosthet Dent 2003; 90:190-193. [Crossref][Googlescholar][Indexed]

- Varadan VK, Vinoy KJ, Gopalakrishnan S. Smart material systems and MEMS: Design and development methodologies. John Wiley and Sons, London. 2006; 432.[Crossref][Googlescholar][Indexed]

- Saavedra G, Neisser MP, Sinhoreti MA, et al. Evaluation of bond strength of denture teeth bonded to heat polymerized acrylic resin denture bases. Braz J Oral Sci 2004; 3:458-464. [Crossref][Googlescholar][Indexed]

- Leles CR, Machadado AL, Vergani CE, et al. Bonding strength between a hard chair side reline resin and a denture base material as influenced by surface treatment. J Oral Rehabil 2001; 28:1153-1157. [Crossref][Googlescholar][Indexed]

- Jacobsen NL, Mitchell DL, Johnson DL, et al. Lased and sandblasted denture base surface preparations affecting resilient liner bonding. J Prosthet Dent 1997; 78:153-158. [Crossref][Googlescholar][Indexed]

- Craig RG, Gibbons P. Properties of resilient denture liners. J Am Dent Assoc 1961; 63:382-392. [Crossref][Googlescholar][Indexed]

- Emmer Jr TJ, Emer TJ, Vaidynathan J, et al. Bond strength of permanent soft denture liners bonded to denture base. J Prosthet Dent 1995; 74:595-601. [Crossref][Googlescholar][Indexed]

- Guler AU, Guler E, Yucel AC, et al. Effects of polishing procedures on color stability of composite resins. J Appl Oral Sci 17 2009; 17:108-112. [Crossref][Googlescholar][Indexed]

- Hachim TM. Evaluation of shear bond strength of silicon based soft liner to the acrylic resin denture base using different polymerization technique with different storage periods in distilled water. J Bagh Coll Dentistry 2012; 24:42-46. [Googlescholar][Indexed]

- Azevedo A, Machado AL, Vergani CE, et al. Hardness of denture base and hard chair side reline acrylic resins. J Appl Oral Sci 2005; 13:291-295. [Crossref][Indexed]

- Hutchings RS, Honegger RW, Sallum MA. Culicidae (Diptera: Culicomorpha) from the central Brazilian amazon: Nhamunda and abacaxis rivers. Zoologia (Curitiba) 2013; 30:1-4. [Crossref][Googlescholar][Indexed]

Author Info

Rawaa Zaher Hassan Zwain1*, Anwar Hussein Jawad2, Rusul Subhi Hassan3 and Dunya Malhan Hanweet4

1Department of Prosthetic, College of Dentistry, University of Kufa, Iraq2Department of Prosthodontics, Department of Health in Najaf, Iraq

3Department of Periodontology, College of Dentistry, University of Kufa, Iraq

4Department of Oral Pathology, College of Dentistry, University of Kufa, Iraq

Citation: Rawaa Zaher Hassan Zwain, Anwar Hussein Jawad, Rusul Subhi Hassan, Dunya Malhan Hanweet, Mode of Adhesion between Soft Reline Material and Denture Base Material, J Res Med Dent Sci, 2023, 11 (01): 109-113.

Received: 28-Oct-2022, Manuscript No. JRMDS-22-65200; , Pre QC No. JRMDS-22-65200 (PQ); Editor assigned: 02-Nov-2022, Pre QC No. JRMDS-22-65200 (PQ); Reviewed: 16-Nov-2022, QC No. JRMDS-22-65200; Revised: 27-Dec-2022, Manuscript No. JRMDS-22-65200 (R); Published: 04-Jan-2023