Research - (2021) Volume 9, Issue 4

Improvement of Organizational and Technological Solutions for the Construction of Sports Facilities to form a Vector of the Nation's Health Rehabilitation

Pavel Oleinik* and Alexandra Zheltaya

*Correspondence: Pavel Oleinik, Technology and Organization of Construction Department in Moscow State University of Civil Engineeri, Russia, Email:

Abstract

The construction of sports facilities is of particular interest. In connection with the tendency for the development of highperformance sports and an increase in the availability of mass amateur sports, a significant number of facilities of the corresponding functional purpose have been built recently: ski slopes, stadiums, bicycle paths, reservoirs. Large-span stadiums with their complex and architecturally expressive forms occupy a special place in this nomenclature. For the construction of these structural systems, the most modern and effective technological solutions should be used. Modern sports facilities are being built according to complex projects, engineers are trying to develop the most comfortable conditions for sports, to make not only a functional building to optimize training processes, but also architecturally beautiful and unique. However, in a number of projects, the organizational and technological solution is developed individually, because the regulatory and technical base does not have the necessary data, in particular, the time rate for the processes for the construction of the pavement that require experimental technical regulation. In the article, the authors analyzed the experience of the Russian Federation and some foreign countries in the alternative organizational and technological design of the technology for the construction of sports facilities coverings. As a result of the study, a block diagram of the design of a work plan for the high-speed construction of a sports facility was formed, considering the decomposition of these works according to the degree of their typification relative to the standards of technical regulation. These developments allow improving the methods of organizational and technological design, considering the introduction of algorithms for the design process of organizational and technological solutions to optimize the development of options for the construction of large-span objects, including based on experimental data and statistics of the construction of similar structural elements. Acceleration of the development of such solutions can significantly reduce the risks of disruptions in the construction of objects of state programs for the rehabilitation of the nation, including the construction of various sports facilities in their schedule to optimize the training processes of elite sports.

Keywords

Management, Organizational and technological solution, Health rehabilitation, Scheduling, Sports facility, Nation's health, Constructiondisease

Introduction

Construction of long-span buildings and structures is a complex process that requires a careful approach of the developer and contractor as well as a sound technology of work. Construction of large-scale objects has its own direction in design, though there is no definition in technical standard base of what a «long-span structure» or a «long-span facility» are (Table 1).

| No. | Source of standard documentation | Classification criterion of a long-span building / structure | ||

|---|---|---|---|---|

| Span, m | Metric area | Cantilever, m | ||

| 1 | Resolution of the Moscow Government No. 567-PP dated June 25, 2006 "On measures to ensure the reliability of civil buildings with long-span structures" | >18 | - | - |

| 2 | "Manual on scientific and technical support and monitoring of buildings and structures under construction, including long-span, high-rise and unique ones" MRDS 02-08, section "Terms and definitions" | >36 | - | - |

| 3 | MDS 20-2.2008 "Temporary recommendations on ensuring the safety of long-span structures from progressive collapse in case of emergency impacts" | >36 | - | - |

| 4 | Town-Planning Code of the Russian Federation "Article 48.1. Highly dangerous, technically complex and unique facilities" | >100 (term «unique» is used) | - | - |

| 5 | Code of Practice dated 25.10.2017 No. 304.1325800.2017 "SP 304.1325800.2017 Structures of long-span buildings and facilities. Rules of operation" | >18 (civil) >30 (industrial) | >50 people | >9 |

Table 1: Classification criterion of a long-span building/structure.

Literature Review

Several regulatory documents [1-5] and scientific sources [6-11] were analyzed and studied, in order to write this paper and fully convey the most relevant and precise information, scrutinize various data and terns.

Method

Public, industrial, and special buildings are usually designed with long spans. The necessity for such structures arises when intermediate supports obstruct the planned work process. The bearing elements of such objects can be made of the following basic materials - in-situ reinforced concrete, prefab reinforced concrete, piece elements. Such long-span buildings are usually made single-span. Facilities of industrial and special type generally are rectangle, while public ones can polygonal-, round- or oval-shaped.

Existing methods for construction of long-span sports facilities on the example of football stadiums

Every country discusses the matter of human life expectancy and healthy lifestyle. The President of Russia gave interesting figures: to date, 54 million Russians take sports on a regular basis, what is almost 40% of the country’s population. Moreover, there has been set a goal to increase this figure to 55% by 2024 [11]. Accordingly, there is a great need for the active construction of sports facilities, including those for major international competitions.

Many sports venues, such as football stadiums, have a large area and exclude, due to the architectural solution, the presence of bearing pillars inside the building, i.e., those buildings are long-span. Sports facilities range by their functional purposes (Table 2). The paper considers those stadiums in more details, the roofing of which was conducted in various methods depending on structural system of cover (Table 3). Having analyzed a number of such sports venues, it becomes clear that distinctive feature of the design and implementation of organizational and process solutions lies primarily in erection of long-span architecturally vivid roofing and facades (Table 4).

| No. | Facility | Description | Athletic discipline |

|---|---|---|---|

| 1 | Sports and recreation facility (premises) | Equipped with special technical means and intended for fitness and health, sports services | All team sports, gymnastics, wrestling, powerlifting |

| 2 | Sports arena | Sports ground with grandstands. Outdoors >1500 people, indoors >500 people. | All team sports, gymnastics |

| 3 | Gym hall | A sports, indoor facility >18 m long, >9 m wide and >5 m high (if the size is smaller, it is deemed a "facility for sports purposes"), there is equipment for different sports or universal. It may be situated in a sports building. . | All team sports, gymnastics, wrestling, powerlifting, track-and-field athletics |

| 4 | Indoor arena | A covered separate or built-in structure that meets the size requirements of the educational and training process and the rules of competitions in sports using large-sized plane structures (fields, sports grounds, etc.) as the main ones. Seats for spectators are possible. | Football, track-and-field athletics, equestrian sport, swimming |

| 5 | Sports complex | A group of similar and different types of volumetric and plane structures for training and competitions, located in the same territory and run by one management. Facilities can be interlocked, located under the same roof or free-standing. | All team sports, gymnastics, wrestling, powerlifting, track-and-field athletics |

| 6 | Stadium | It is a complex with sports arena. | Football, cycling, running, track-and-field athletics |

| 7 | Universal Sports and Entertainment (Demonstration) Hall (Sports Palace) | Arena for 1000 and more people. The sizes of the main ground and the auditorium are suitable for different sports. Versatility is achieved through transformation. | Team sports, hockey, figure skating |

| 8 | Swimming pool | An open-air or indoor facility with a main swimming-bath of at least the size set by the competition rules. It is possible to combine conditions for several sports in one bath It is possible to arrange seats for spectators. | Competitive swimming, water polo, springboard diving, synchronized swimming |

| 9 | Shooting range | It is a complex, consisting of open or semi-enclosed facilities. | Various kinds of shooting |

| 10 | Skiing center | A complex of facilities, including changing rooms, ski storage and other service rooms and trails for training and skiing. A skiing run may include a ski stadium - a start and finish area >400m in length and width with a judge's room, grandstands for spectators | Alpine skiing, snowboarding, biathlon, orienteering, freestyle, ski jumping |

Table 2: Classification of sports facilities by functional purpose.

| No. | Type of roof structure | Options of roofing structural system | Description | Drawing |

|---|---|---|---|---|

| 1 | Canopy above the stadium stands (cantilever-beam system) | Stadium in Hong Kong | Canopy roof of Hong Kong stadium is made with wave-like folded plates rom synthetic materials, which are placed on the metal-elements structure | https://www.ok-t.ru/studopediaru/baza11/1165364222100.files/image734.jpg |

| 2 | In-situ reinforced concrete cantilever beams | Stadium in Düsseldorf, Germany | One end of the beams rests on the girder of in-situ triangular reinforced concrete frames, and they are suspended by cables to the upper part of the girder at two other points. The section of the beam is T-shaped, between the beams the covering is a suspended reinforced concrete cylindrical shell. | https://www.ok-t.ru/studopediaru/baza11/1165364222100.files/image738.jpg |

| 3 | Steel cables | Cricket ground in London, UK | Canopy tent structure covers the stands of the renovated cricket venue in London. To steel tubular masts attached cables and suspended a dome made of transparent synthetic material - polycarbonate. | https://www.ok-t.ru/studopediaru/baza11/1165364222100.files/image740.jpg |

Table 3: Classification of the main structural systems of stadium roofs.

| No. | Name | Purpose | Capacity, people | Unique elements (non-standard structural / architectural / organizational and process solutions, previously not implemented in civil engineering) | Photos from Internet sources |

|---|---|---|---|---|---|

| 1 | The Volgograd Arena, Volgograd, Russia | Football stadium | 45,568 | Roofing | https://avatars.mds.yandex.net/get-altay/1007647/2a00000163977ca2530e3162f73eaa6ee0c3/XXL |

| 2 | Otkritie Arena, Moscow, Russia | Football stadium | 45,360 | Roofing, facade | https://pokrov-streshnevo.mos.ru/upload/medialibrary/a7b/ps-upr-dvizhenie.jpg |

| 3 | Bilbao Arena, Bilbao in the province of Biscay, Spain | Basketball arena | 8,793 | Roofing, facade | https://i.pinimg.com/originals/76/ac/1b/76ac1b44588565ab9e25bd456b7dd3c1.jpg |

Table 4: Examples of sports facilities.

The Volgograd Arena’s roof resembles a bicycle wheel made from strong steel cables. The facility is located in a historical place; its compactness is achieved due to the canonical shape of the facade tapering downwards. The pattern on its self-supporting structures of the facade is inspired by local traditional weaving from canes and a firework at the celebration of the Victory in the Great Patriotic War. Primarily, the main pre-construction activities were performed, including the dismantling and disposal of building structures of the former Central stadium and the previously existing utility systems. Then the work of the principal construction period – making a foundation pit and a foundation slab – was performed. Further, the stadium's supporting structures were erected, on-site utility systems were laid, cast-in-situ structures and stands of the stadium were constructed with a total volume of more than 120 thousand m3 of concrete. In 2017, the installation of horizontal structures of the stadium roof was completed, including a unique cable-stayed system with a membrane covering [7,8].

When erecting Otkritie Arena, one of the trickiest moments was to assemble the stadium’s roofing system. The workers mounted 8700 tons of metal at a height of 29 to 36 meters with the help of a large number of complex lifting mechanisms. The roof structure involves two longitudinal trusses (an architectural truss is a building part installed for the rigidity and strength of the structure. It is usually used when building complex spans) installed along the football pitch, and two transverse trusses forming a crosslinked system over the stadium. The roof trusses framed along the upper and lower chords with steel sheets 4 mm thick, were assembled on the ground on special trolleys in just near the facility to cover. The trolleys had conductors and devices to ensure the necessary accuracy of putting together the roof elements. The design of the trolleys allowed them to move along horizontal and inclined rail tracks with trusses fixed on them. To lift the trolleys to the design level, two inclined mounting beams were installed. The trolleys with the next roofing block were moved via two block and tackle systems. After reaching the design mark, the trolleys rested against a special buffer; the roofing block was lowered onto steel cages and pushed into the final position by rolling-on method with the help of two light blocks and tackles. In the final position it was first raised via jacks to release the rollers, and then lowered back to the final position. One of the advantages of this method is that there is no need to use a crane of large-tonnage capacity. The facade of the stadium is made of cement-mineral panels. Their advantage consists in their ability to take a wide range of shapes. The construction project was developed by the architect bureau AECOM. Initially, they wanted to make the facade of blocks and bricks, but later decided to use newer technologies of "dry construction". The walls of the facade are resistant to moisture, which is an important factor, since only one of the four stands is heated. The scaly facade was designed by Dexter Moren Associates, the British bureau. The design of the outer walls is such that they are effectively protected from atmospheric agents [9].

A noteworthy green facade solution was made for Bilbao Arena in Spain. The structure of the arena is inspired by a leaf of a tree. The facade plating is made of leaf-like steel plates that can be removed to allow lighter and air to enter the building. This design helps cut expenses on electricity; the halls are well-aerated; an air conditioner is not required. The largest arena is located at the top of the building, while the smaller sports grounds are at the lower part of the complex. The upper arena is naturally illuminated due to glass partition-walls of utility spaces which let the outdoor light in. There is a rainwater collection tank, which is not common for this type of structure. Water is collected in a special container and transferred to the disposal of the city municipality. This water is further used for washing the streets of Bilbao. The sports arena occupying 30,808 m2 requires a huge amount of electricity, but due to its energy efficient design the actual consumption is reduced many times over. The total area of the building is 80,000 m2, and the problem of air conditioning of such a space is also solved in environmentally friendly way: by “perforation” of the green facade [10-15].

Proceeding from architectural and design solutions for similar projects, some options of organizational and process design also contain uncommon solutions. For instance, in the Russian Federation besides the concept design and detailed design documentation, which is developed by engineering companies, certain regulations impose upon a contractor a duty to develop organizational and process solutions formalized in the form of production documents (Work execution design, Flowsheets of operational sequence, Production procedures) [2]. Such organizational and process solutions are prescribed even at the design stage in the Construction Management Plan. However, this solution requires a deeper investigation into options for performing works at the stage of construction.

Results

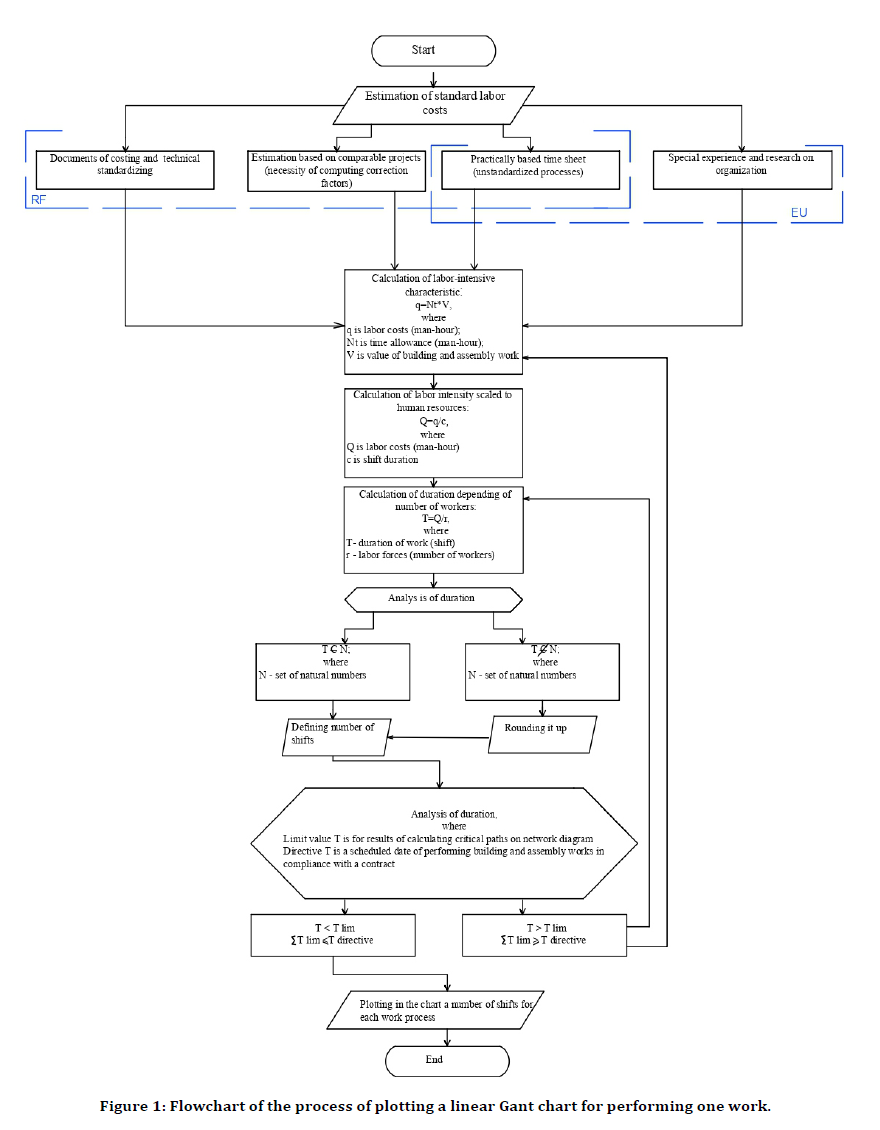

A building or a structure should be erected in compliance with an activity schedule contained in the process control documentation. The procedure of compiling such a schedule, for construction of unique long-span sports facilities, is shown in the flowchart below (Figure 1).

Figure 1. Flowchart of the process of plotting a linear Gant chart for performing one work.

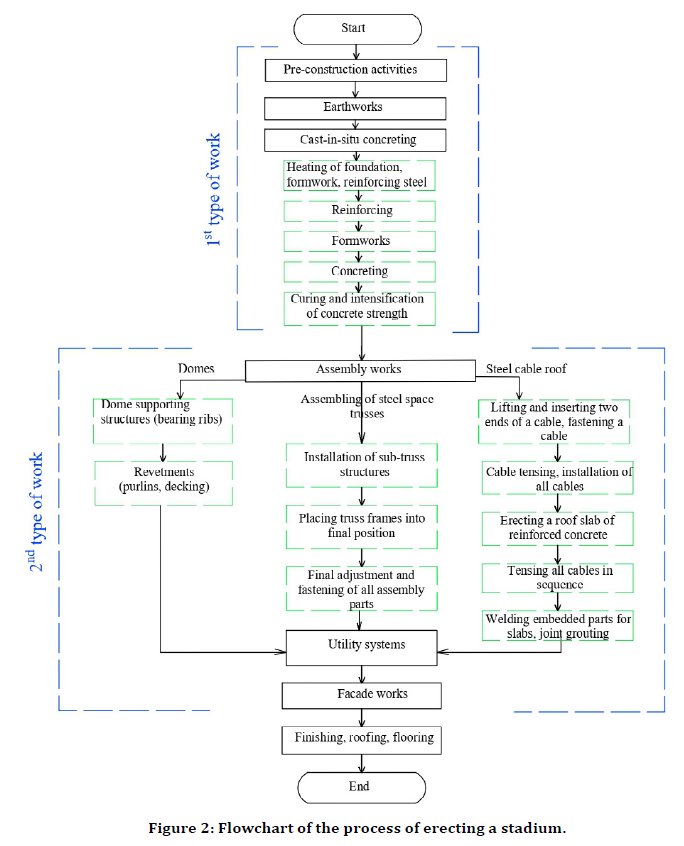

As one can see from the chart above, the process of compiling an activity schedule is based on technical rationing. Time allowance is given in a number reference papers, yet there are no some of certain building and assembly works performed when erecting a unique structure with the use of unstandardized technologies. Within the framework of this study, the authors propose to resolve the complex of building and assembly works associated with construction of sports facilities into elementary processes, which are offered to systemize by splitting into certain groups on the grounds of standardization of process rating. After analyzing a number of projects, two types of work are given (Figure 2).

Figure 2. Flowchart of the process of erecting a stadium.

In terms of organizational and process solution, the first type of work is like the one pertaining to projects meant for other purposes. The second type comprises works that require quite timeconsuming process of determining time rates (practically-based time sheet on site). However, after resolving these groups of works into processes one can distinguish “standardized” ones, technical rate setting of which require no additional time. Exotic technology for erecting stadium’s roofing such as a method of circular lengthwise launching may serve as an example of trial design. Another one – suspended cantilever method, which is more common and time-tested, may be used as an example as well (Table 5).

| №п/п | Works | Processes | Mathematical formalization |

|---|---|---|---|

| I | 1st category works on erecting sports facilities that do not require practice-based rate setting |

||

| I1 | In-situ concreting [1.1] | Reinforcing |  |

| I2 | Formworks |  |

|

| I3 | Concreting |  |

|

| I4 | Curing and intensification of concrete strength |  |

|

| I5 | Maintenance |  |

|

| II | 2nd category works on erecting sports facilities that require unstandardized mechanical means | ||

| II1 | Suspended cantilever method [1.2] | Assembly of steelwork of external abutments |  |

| II2 | Preparation of basement for vertical support members |  |

|

| II3 | Pre-assembly activities, mounting, ground level assembly works |  |

|

| II4 | Подача монтажного блока на рабочей площадке временных опор Conveying sub-assemblage on temporary supports’ site |

|

|

| II5 | Pre-assembly of sub-assemblages |  |

|

| III | 3rd category works on erecting sports facilities that require practice-based rate setting | ||

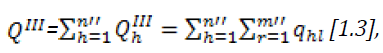

| III1 | Method of circular lengthwise launching [1.3] | Installation of launching nose |  |

| III2 | Assembly of auxiliary mounting elements to perform launching |  |

|

| III3 | Installation of jack, winches and guide casings |  |

|

| III4 | Elementwise supply of launching to a bay with regular assembly |  |

Table 5: Example for assembling space trusses.

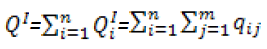

Mathematical formalization of the calculation of labor costs for building and assembly processes and works is presented in the formulas.

Where

Total labor intensity of building and assembly

works of the 1st category.

Total labor intensity of building and assembly

works of the 1st category.

Labor intensity of the i-th work of the 1st

category.

Labor intensity of the i-th work of the 1st

category.

Sum of labor intensity of j processes of

the i-th work of the 1st category.

Sum of labor intensity of j processes of

the i-th work of the 1st category.

I:Counting number of works in this category.

J:Counting number of the work process in this category.

N: Number of works in this category.

M: Number of work processes in this category

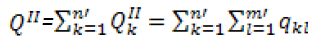

Where

Total labor intensity of building and assembly

works of the 2nd category.

Total labor intensity of building and assembly

works of the 2nd category.

Labor intensity of the k-th work of the 2nd

category.

Labor intensity of the k-th work of the 2nd

category.

Sum of labor intensity of l processes of

the k-th work of the 2nd category.

Sum of labor intensity of l processes of

the k-th work of the 2nd category.

K: Counting number of works in this category.

L: Counting number of the work process in this category.

n’– Number of works in this category.

m’- Number of work processes in this category

Where

Total labor intensity of building and

assembly works of the 3rd category.

Total labor intensity of building and

assembly works of the 3rd category.

Labor intensity of the h-th work of the 3rd

category.

Labor intensity of the h-th work of the 3rd

category.

Sum of labor intensity of r processes of

the h-th work of the 3rd category.

Sum of labor intensity of r processes of

the h-th work of the 3rd category.

H: Counting number of works in this category.

r: Counting number of the work process in this category.

n’’: Number of works in this category.

m’’:Number of work processes in this category.

Conclusion

The introduction of an algorithmic approach to elaboration and technical and economic assessment of organizational and process design solutions in the case of trial design of technology for assembling large-span structures for sports buildings and facilities allows improving and optimizing procedures of working out organizational and process documents through resolving building and assembly works into categories. This allows maximizing the use of experimental data on erection of such objects. Algorithmization of organizational and process design reveals the following tasks that require further study:

✓ Standardization of organizational and process solutions for the construction of unique sports facilities to optimize organizational and process design in general and the possibility to timely develop various options for assembly technology (including uncommon non-standard technologies).

✓ Application of the described prerequisites for creating an automated algorithm for the development of rational organizational and process solutions for the construction of unique large-span sports facilities (and corresponding software).

The proposed standardizing of works was used when working out an organizational and process model for the construction of several sports facilities. The example is trial designs of a technology for assembling the roofing of Otkritie Arena in Moscow (Russia). Depending on a type of structural properties of sports facilities’ roofing, elaboration of various standard organizational and process models allows accelerating the development of organizational and process documentation, determination of key production parameters (total labor intensity, duration, cost) according to a way of implementation of a corresponding technology. Trial design also optimizes the range of tasks associated with technical regulation of building and assembly processes at site.

References

- Regulatory document: Classification of physical culture and sports facilities. Appendix to the decree of the state committee for sports of the USSR No. 2/2 dated April 4, 1988.

- Regulatory document: SP 48.13330.2019 Organization of construction 2019.

- Regulatory document: Town-planning code of the Russian federation 2004; 318.

- Regulatory document: Guidance documents in construction MDS 20-2.2008. Temporary recommendations for ensuring the safety of large-span structures from avalanche-like (progressive) collapse in case of emergency”; 2008, page 5.

- Regulatory document: SP 304.1325800.2017. Construction of long-span buildings and structures. Operating rules 2017’ 4.

- Ageeva EY, Filippova MA. Large-span sports facilities: Architectural and structural, ministry of education and science of the Russian federation state educational institution of higher professional education Nizhny Novgorod state university of architecture and civil engineering, Nizhny Novgorod 2014; 3-7.

- Chizhenok AE., Construction of the Volgograd Arena 2017.

- Syrtsova MV. Specifics of the construction process. Progressive modern methods of building construction on the example of the Volgograd-Arena 2018.

- Zykeev GA, Petrov EV. Selected reports of the 65th anniversary university sci-tech conference of students and young scientists. Specifics of the construction of large-span buildings on the example of Otkrytie Arena, Tomsk State University of Architecture and Civil Engineering 2019; 210-214.

- Langinen E. Eco-friendly green Bilbao Arena 2020.

- Decree of the president of the Russian Federation: Putin VV. On national goals and strategic objectives of the development of the Russian Federation through to 2024. 2018.

- https://www.matec-conferences.org/articles/matecconf/abs/2017/31/matecconf_rsp2017_00130/matecconf_rsp2017_00130.html

- https://www.matec-conferences.org/articles/matecconf/abs/2018/52/matecconf_esci2018_05010/matecconf_esci2018_05010.html

- https://www.matec-conferences.org/articles/matecconf/abs/2018/110/matecconf_ipicse2018_05037/matecconf_ipicse2018_05037.html

- https://www.matec-conferences.org/articles/matecconf/abs/2019/14/matecconf_gccets2018_07024/matecconf_gccets2018_07024.html

Author Info

Pavel Oleinik* and Alexandra Zheltaya

Technology and Organization of Construction Department in Moscow State University of Civil Engineeri, Moscow, RussiaCitation: Pavel Oleinik, Alexandra Zheltaya, Improvement of Organizational and Technological Solutions for the Construction of Sports Facilities to form a Vector of the Nation's Health Rehabilitation, J Res Med Dent Sci, 2021, 9 (4): 353-360.

Received: 29-Mar-2021 Accepted: 14-Apr-2021