Research - (2020) Advances in Dental Surgery

Effect of Different Prestretchings on Force Decay of Synthetic Orthodontic Elastomeric Modules at Different Time Intervals (An In vitro Study)

Safa Munir Abdulsattar* and Iman I Al-Sheakhli

*Correspondence: Safa Munir Abdulsattar, Department of Orthodontics, College of Dentistry, University of Baghdad, Iraq, Email:

Abstract

Background: This study aims to investigate the effect of prestretching on the force degradation of elastomeric chains. Materials and methods: 500 samples from Ormco company both generation I and generation II elastics were divided into control and experimental groups for prestretching including 1 time 50% prestretching, 3 times 50% prestretching, 1 time 75% prestretching and 3 times 75% prestretching groups. Experimental groups are prestretched in one or three stretchings in quick sequential manner using dental clamp holder inside boxes made to give an increase of 50% or 75% of the elastics initial length. Samples were applied to pins fixed in acrylic plates made with a fixed distance so that all control samples deliver 200 grams of force initially. Samples were stored in artificial saliva at 37C in an incubator. Forces were measured at five-time intervals. Statistical analysis included one-way analysis of variance ANOVA test, Tukey HSD test, and independent t-test. Results: Pattern of force degradation was similar in all durations being higher in control group followed by 1 time 50% prestretching, 3 times 50% prestretching, 1 time 75% prestretching and 3 times 75% prestretching group. There was non-significant difference between 1 time 50% prestretching and 3 times 50% prestretching and between 1 time 75% prestretching and 3 times 75% prestretching in most of the testing periods. Conclusion: Generation I elastics showed more force degradation than generation II in all groups and time intervals with more force decayed in the sixth week. 75% prestretching groups showed least force loss compared to 50% and control groups. Number of times of prestretching is of questionable clinical benefit.

Keywords

Prestretching, Elastomeric modules, Force decay

Introduction

Orthodontic elastomeric chains have wide use in orthodontic practice due to its versatility and different modalities of mechanics. It consists of amorphous polymers of polyurethane [1,2]. Synthetic elastomeric chains are hygienic, inexpensive, easily manipulated, and need no patient cooperation. In clinical practice, it is used mainly for rotation correction, diastema closure and space closure [2].

However, it has disadvantages to use, including plastic deformation, color changing [3], retention of biofilms. In addition, it rapidly undergoes stress relaxation and force decay resulting in less than optimal force for tooth movement [2,4-6].

Therefore, some authors have reported prestretching of elastics before use [2,4-7]. This was as an attempt to minimize the abrupt force decay especially in the first hours of use [8]. Young et al. [9] reported that prestretching in air had significantly increased the remaining force in day one by 17% to 25% compared with control group. Chang et al. [10] recommended 100% prestretching instantaneously for clinical use. Brooks et al. [11] reported that heating the elastomeric modules decreased the force to 30% and 20% of the initial force at the first hour and one month, respectively. furthermore, when prestretching and then heating the elastomeric modules, the remaining force of elastics was about 50% and 31% at the first hour and one month, respectively. Therefore, it was suggested that prestretching the elastomeric modules could at least partly decrease the force decay caused by heating. Brantley et al. [12] reported that prestretching the elastomeric chains in water is more effective in decreasing the force decay compared to prestretching in air. However, Baty et al. [8] reported that prestretching elastomeric chains has small benefits and is of no clinical significance.

The aim of study was to investigate the effect of prestretching on force decay of orthodontic elastomeric modules.

Materials and Methods

A total of 500 samples were included from Ormco generation I and generation II elastomeric chains, 250 sample for each. Samples were transparent, short filament, and cut into five units. Samples for each generation were divided into experimental and control groups. The experimental groups were further divided into four groups: one time 50% prestreching group, three times 50% prestreching group, one time 75% prestreching group, and three times 75% prestretching groups. Accordingly, four boxes were made precisely with a CNC (computer numerical control) machine particularly for the purpose of precise amount of prestretching with an inner distance to give an increase of 50% or 75% of the sample initial length. The inner side of each box was made with the measures illustrated in Table 1 (an extra 1 mm was added for each measure to compensate for the size of ball ends of the dental dam clamp holder).

| Type of elastomeric module | Initial length of a five-bond sample (mm) | Measure of inner side of CNC box for 50% pre stretching (mm) | Measure of inner side of CNC box for 75% pre stretching (mm) |

|---|---|---|---|

| Ormco power chain generation I | 14.85 | 23.27 | 26.98 |

| Ormco power chain generation II | 15.57 | 24.35 | 28.24 |

Table 1: Measures of the inner side of CNC box for each type of elastomeric modules.

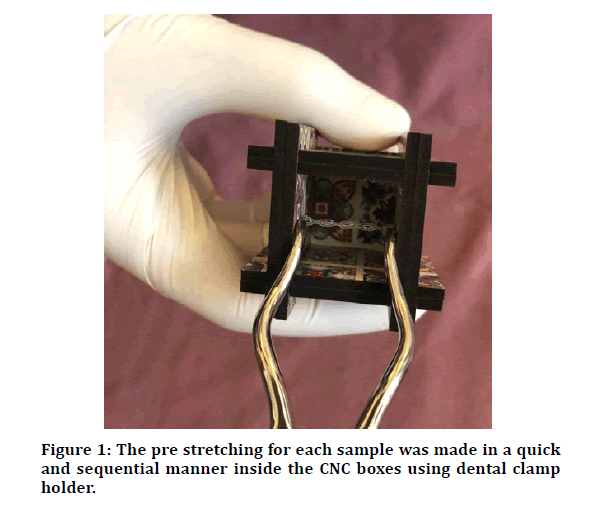

The pre stretching for each sample was made in a quick and sequential manner [13] inside the CNC boxes using dental clamp holder as showm in Figure 1.

Figure 1: The pre stretching for each sample was made in a quick and sequential manner inside the CNC boxes using dental clamp holder.

Acrylic boards were made for storage of the sample as shown in Figure 2. Each board contain a group of metal pins circular in cross section and 1 mm in diameter. These pins were arranged in two parallel lines. Each board include twenty pins, the distance between pins in the same line is (1 cm), while the distance between parallel pins is different for each type of elastomeric modules. Each type is stretched separately in a pilot study to give 200 gm of force in order to simulate the clinical situation of canine retraction [14] and the mechanical stress in the oral environment and then the fixed distance between the pins is decided accordingly for each type. The distances between the pins were 18.4 mm and 20.7 mm for Ormco generation I and II elastomeric chains, respectively.

Figure 2: Elastomeric chains held between the pins of acrylic boards and immersed in artificial saliva.

The samples were held stretched into the boards, immersed in artificial saliva, and stored in an incubator at 37C during the time of the study.

Forces were measured at five-time intervals: initially (not stored in saliva), after 1 day, 1 week, 3 weeks, and 6 weeks. At each testing period, new elastomeric samples were used to avoid fatigue of the samples by excessive handling [15]. All measurements were made with a digital force gauge. Measurements of force were taken by securing one end of the sample to the pin and fixing the other end to the digital force. For standardization of measurement readings, all the samples were stretched to the same distance between the pins of the acrylic board as were maintained during the testing period. All samples were measured and handled with the same manner and at the same horizontal and vertical distance on the measuring boards. Statistical analysis was made using one-way analysis of variance ANOVA test, Tukey HSD test, and independent t-test.

Results

Effect of prestretching on force decay of elastomeric modules

The descriptive statistics and groups' differences of the percent of force degradation for the Ormco generation I and generation II elastomeric chains in different time intervals were presented in Tables 2-5 respectively.

| Duration | Groups | Descriptive statistics | Comparison | ||||

|---|---|---|---|---|---|---|---|

| Mean | S.D. | Min. | Max. | F-test | p-value | ||

| 1 day | I | 55.75 | 2.058 | 52.5 | 57.5 | 43.226 | 0 |

| II | 52.873 | 1.84 | 50 | 55.56 | |||

| III | 51.41 | 2.973 | 47.37 | 55.26 | |||

| IV | 48.133 | 2.857 | 44.12 | 54.05 | |||

| V | 42.315 | 2.444 | 39.39 | 47.22 | |||

| 1 week | I | 61.75 | 2.058 | 57.5 | 65 | 31.308 | 0 |

| II | 58.805 | 3.055 | 55.26 | 64.1 | |||

| III | 56.325 | 3.821 | 51.35 | 61.54 | |||

| IV | 48.914 | 5.42 | 41.18 | 56.76 | |||

| V | 44.909 | 4.593 | 40.63 | 52.78 | |||

| 3 weeks | I | 65 | 2.635 | 60 | 67.5 | 25.422 | 0 |

| II | 62.196 | 2.299 | 58.33 | 66.67 | |||

| III | 62.856 | 3.48 | 56.76 | 67.5 | |||

| IV | 59.131 | 5.057 | 55.56 | 68.42 | |||

| V | 51.594 | 1.953 | 48.48 | 55.56 | |||

| 6 weeks | I | 73.75 | 1.768 | 70 | 75 | 6.692 | 0 |

| II | 71.051 | 3.391 | 65.79 | 74.36 | |||

| III | 70.183 | 4.079 | 64.86 | 75 | |||

| IV | 68.518 | 4.017 | 61.76 | 72.97 | |||

| V | 65.88 | 4.081 | 60.61 | 72.22 | |||

Table 2: Descriptive statistics and group difference of the percentage of force decay in Generation I Ormco elastics.

| Groups | One day | One week | 3 weeks | 6 weeks | |||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | p-value | Mean | p-value | Mean | p-value | Mean | p-value | ||

| Difference | Difference | Difference | Difference | ||||||

| I | II | 2.877 | 0.087 | 2.945 | 0.468 | 2.804 | 0.326 | 2.699 | 0.453 |

| III | 4.34 | 0.003 | 5.425 | 0.029 | 2.144 | 0.592 | 3.567 | 0.188 | |

| IV | 7.617 | 0 | 12.836 | 0 | 5.869 | 0.002 | 5.232 | 0.017 | |

| V | 13.435 | 0 | 16.841 | 0 | 13.406 | 0 | 7.87 | 0 | |

| II | III | 1.463 | 0.679 | 2.48 | 0.632 | -0.66 | 0.991 | 0.868 | 0.982 |

| IV | 4.74 | 0.001 | 9.891 | 0 | 3.065 | 0.242 | 2.533 | 0.516 | |

| V | 10.558 | 0 | 13.896 | 0 | 10.602 | 0 | 5.171 | 0.019 | |

| III | IV | 3.277 | 0.037 | 7.411 | 0.001 | 3.725 | 0.1 | 1.665 | 0.835 |

| V | 9.095 | 0 | 11.416 | 0 | 11.262 | 0 | 4.303 | 0.072 | |

| IV | V | 5.818 | 0 | 4.005 | 0.178 | 7.537 | 0 | 2.638 | 0.476 |

I: Control, II: 1 time 50% prestretching, III: 3 times 50% prestretching, IV: 1 time 75% prestretching, III: 3 times 75% prestretchin

Table 3: Tukey HSD test after ANOVA.

| Duration | Groups | Descriptive statistics | Comparison | ||||

|---|---|---|---|---|---|---|---|

| Mean | S.D. | Min. | Max. | F-test | p-value | ||

| 1 day | I | 34 | 2.687 | 30 | 37.5 | 127.05 | 0 |

| II | 27.521 | 5.468 | 17.14 | 33.33 | |||

| III | 22.892 | 2.222 | 18.18 | 25.71 | |||

| IV | 13.95 | 2.182 | 10 | 17.65 | |||

| V | 5.584 | 1.612 | 3.13 | 6.9 | |||

| 1 week | I | 47 | 3.496 | 45 | 55 | 75.303 | 0 |

| II | 39.941 | 4.437 | 34.29 | 48.72 | |||

| III | 35.899 | 3.195 | 30.3 | 41.67 | |||

| IV | 23.145 | 4.818 | 13.33 | 29.41 | |||

| V | 20.581 | 4.271 | 13.33 | 25.81 | |||

| 3 weeks | I | 54.5 | 1.972 | 50 | 57.5 | 35.651 | 0 |

| II | 49.407 | 3.551 | 43.24 | 55.56 | |||

| III | 43.294 | 5.042 | 34.29 | 48.65 | |||

| IV | 35.002 | 5.322 | 23.33 | 40.63 | |||

| V | 34.062 | 6.393 | 23.33 | 40 | |||

| 6 weeks | I | 59.5 | 3.073 | 55 | 62.5 | 34.044 | 0 |

| II | 55.542 | 3.86 | 50 | 61.54 | |||

| III | 52.915 | 2.387 | 48.48 | 56.76 | |||

| IV | 43.483 | 5.012 | 36.67 | 50 | |||

| V | 42.886 | 5.018 | 34.48 | 50 | |||

Table 4: Descriptive statistics and group difference of the percentage of force decay in Generation II Ormco power chain.

| Groups | One day | One week | 3 weeks | 6 weeks | |||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | p-value | Mean | p-value | Mean | p-value | Mean | p-value | ||

| Difference | Difference | Difference | Difference | ||||||

| I | II | 6.479 | 0 | 7.059 | 0.003 | 5.093 | 0.13 | 3.958 | 0.195 |

| III | 11.108 | 0 | 11.101 | 0 | 11.206 | 0 | 6.585 | 0.005 | |

| IV | 20.05 | 0 | 23.855 | 0 | 19.498 | 0 | 16.017 | 0 | |

| V | 28.416 | 0 | 26.419 | 0 | 20.438 | 0 | 16.614 | 0 | |

| II | III | 4.629 | 0.016 | 4.042 | 0.194 | 6.113 | 0.043 | 2.627 | 0.59 |

| IV | 13.571 | 0 | 16.796 | 0 | 14.405 | 0 | 12.059 | 0 | |

| V | 21.937 | 0 | 19.36 | 0 | 15.345 | 0 | 12.656 | 0 | |

| III | IV | 8.942 | 0 | 12.754 | 0 | 8.292 | 0.003 | 9.432 | 0 |

| V | 17.308 | 0 | 15.318 | 0 | 9.232 | 0.001 | 10.029 | 0 | |

| IV | V | 8.366 | 0 | 2.564 | 0.629 | 0.94 | 0.992 | 0.597 | 0.997 |

I: Control, II: 1 time 50% prestretching, III: 3 times 50% prestretching, IV: 1 time 75% prestretching, III: 3 times 75% prestretching

Table 5: Tukey HSD test after ANOVA.

The pattern of force degradation for both types of elastics was similar in all durations being higher in control group followed by 1 time 50% prestretching, 3 times 50% prestretching, 1 time 75% prestretching and lastly 3 times 75% prestretching group. The differences among different groups were statistically highly significant as indicated by ANOVA test.

Additionally, post hoc Tukey HSD test between groups of generation I elastics revealed some groups showed significant difference and the other not with no significant difference between 1 time 50% prestretching and 3 times 50% prestretching in all durations and between 1 time 75% prestretching and 3 times 75% prestretching groups in the first and sixth weeks as shown in Table 4.

Moreover, post hoc Tukey HSD test between groups of generation II elastics revealed some groups showed significant difference and the other not, but the most important finding was the non-significant difference between 1 time 50% prestretching and 3 times 50% prestretching in the first and sixth weeks and between 1 time 75% prestretching and 3 times 75% prestretching in the first, third and sixth weeks as shown in Table 5.

Effect of elastomeric chains' type on the force degradation

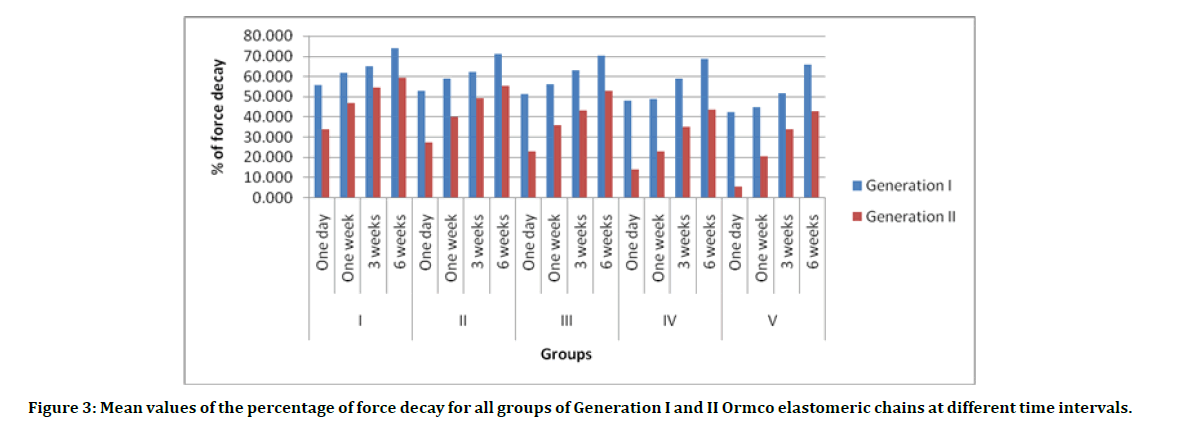

The mean values and standard deviation of the percent of force degradation with the comparison between the two types of Ormco elastomeric chains were presented in Table 6. The mean percentages were presented in Figure 3. Generation I type showed significantly more force degradation than generation II in all groups and time intervals as indicated by independent sample t-test with more force decayed in the sixth week.

Figure 3: Mean values of the percentage of force decay for all groups of Generation I and II Ormco elastomeric chains at different time intervals.

| Groups | Duration | Generation I | Generation II | Comparison | p-value | |||

|---|---|---|---|---|---|---|---|---|

| Mean | S.D. | Mean | S.D. | Mean difference | t-test | |||

| I | One day | 55.75 | 2.058 | 34 | 2.687 | 21.75 | 20.319 | 0 |

| One week | 61.75 | 2.058 | 47 | 3.496 | 14.75 | 11.497 | 0 | |

| 3 weeks | 65 | 2.635 | 54.5 | 1.972 | 10.5 | 10.088 | 0 | |

| 6 weeks | 73.75 | 1.768 | 59.5 | 3.073 | 14.25 | 12.71 | 0 | |

| II | One day | 52.873 | 1.84 | 27.521 | 5.468 | 25.352 | 13.896 | 0 |

| One week | 58.805 | 3.055 | 39.941 | 4.437 | 18.864 | 11.073 | 0 | |

| 3 weeks | 62.196 | 2.299 | 49.407 | 3.551 | 12.789 | 9.56 | 0 | |

| 6 weeks | 71.051 | 3.391 | 55.542 | 3.86 | 15.509 | 9.546 | 0 | |

| III | One day | 51.41 | 2.973 | 22.892 | 2.222 | 28.518 | 24.297 | 0 |

| One week | 56.325 | 3.821 | 35.899 | 3.195 | 20.426 | 12.969 | 0 | |

| 3 weeks | 62.856 | 3.48 | 43.294 | 5.042 | 19.562 | 10.097 | 0 | |

| 6 weeks | 70.183 | 4.079 | 52.915 | 2.387 | 17.268 | 11.554 | 0 | |

| IV | One day | 48.133 | 2.857 | 13.95 | 2.182 | 34.183 | 30.074 | 0 |

| One week | 48.914 | 5.42 | 23.145 | 4.818 | 25.769 | 11.236 | 0 | |

| 3 weeks | 59.131 | 5.057 | 35.002 | 5.322 | 24.129 | 10.393 | 0 | |

| 6 weeks | 68.518 | 4.017 | 43.483 | 5.012 | 25.035 | 12.325 | 0 | |

| V | One day | 42.315 | 2.444 | 5.584 | 1.612 | 36.731 | 39.675 | 0 |

| One week | 44.909 | 4.593 | 20.581 | 4.271 | 24.328 | 12.267 | 0 | |

| 3 weeks | 51.594 | 1.953 | 34.062 | 6.393 | 17.532 | 8.294 | 0 | |

| 6 weeks | 65.88 | 4.081 | 42.886 | 5.018 | 22.994 | 11.242 | 0 | |

Table 6: Descriptive statistics and brand difference of the percentage of force decay in Ormco power chain.

Discussion

This study was carried out to find out the effect of prestretching of different elastomeric chains as an attempt to reduce the abrupt force decay in the first hours.

The overall behavior of the force decay for all groups showed that the force decay was increased over time. Examination of Table 6 reveals that generation I type showed significantly more force degradation than the generation II in all the groups and time intervals with more force decayed in the sixth week. Concerning Ormco generation I elastics, most of the force loss was with in the first day with a range of 42.315% - 55.750% followed by a steady decline. While for Ormco generation II elastics, force loss with in the first day ranges from 5.584% - 34% and the force decay curve shows a gradual force loss over the entire testing periods. This is related to the alterations in the viscosity of the elastic material of each type leading to different force/ relaxation ratios. This range of force loss come in agreement with the outcomes of Howard et al. [16]; Lu et al. [17]; Russel et al. [18]; Santos et al. [19]; Balhoff et al. [20], Mohammed et al. [21], Abdullah et al. [22] while it disagrees with Andreasen and Bishara [4] who found different range with 75% of force decay after the first day.

About the effect of prestretching, results revealed that there was significant difference in mean percent of force decay between control group and prestretching groups in most of the testing period for both types of elastomeric chains. Pre-stretching of the elastomeric chains alleviated the large initial load relaxation, result in a more constant force delivered and improve a constancy of the percent of the force loss. This effect of pre-stretching could be explained based on abrupt plastic deformation, which was obtained before use that improved constancy of force delivery and lessen force degradation after placement but not cancel it. In addition, prestretching in air also enhances the chemical process of aging in the presence of oxygen and light because the stretched bonds react more readily to these factors than do the unstretched and this agrees with others.

Regarding the extent of prestretching, there was significant difference in mean percent of force decay between 50% and 75% prestretching groups for almost all testing periods and in all types of elastomeric chains with 75% prestretching groups showing least percent of force decay. This may be due to differences in the spatial rearrangement of molecules within the polymer structure with different extensions that lead to changes in the rate and pattern of load/ relaxation so that the greater the stretch, the more force decay initially but then it continues with a lower rate of load/relaxation ending in less force loss.

Regarding the times of prestretching, there was no significant difference in mean percent of force decay between 1 time 50% prestretching and 3 times 50% prestretching and between 1 time 75% prestretching and 3 times 75% prestretching in most of the testing periods and for both types of elastomeric chains. This may be explained that the abrupt force decay occurred from the first time of prestretching and permanent deformation starts with the original stretch. Therefore, repeating the process would be of questionable clinical benefit.

Conclusion

Pre-stretching of elastomeric chains improved their initial rapid force decay behavior, resulting in less force loss at the end of the testing period, prestretching for 75% of the elastomeric chains' initial length showing the least percent of force decay compared to 50% prestretching. Regardig the company products, generation II Ormco power chains showed the least force loss over the entire testing periods compared to generation I Ormco power chains.

References

- De Genova DC, Ledoux PM, Weinberg R, et al. Force degradation of orthodontic elastomeric chains: a product comparison study. Am J Orthod 1985; 87:377-384.

- Young J, Sandrik JL. The influence of preloading on stress relaxation of orthodontic elastic polymers. Angle Orthod 1979; 49:104-109.

- Arruda PC, Matta ENR, Silva SC. Influence of the degree of activation in plastic deformation of orthodontic elastic chains. Pesq Bras Odontoped Clin Integr 2011; 11:85-90.

- Andreasen GF, Bishara SE. Comparison of alastik chains with elastics involved with intra-arch molar to molar forces. Angle Orthod 1970; 40:151-158.

- Eliades T, Eliades G, Silikas N, et al. Tensile properties of orthodontic elastomeric chains. Eur J Orthod 2004; 26:157-162.

- Taloumis LJ, Smith TM, Hondrum SO, et al. Force decay and deformation of orthodontic elastomeric ligatures. Am J Orthod 1997; 111:1-11.

- Wong AK. Orthodontic elastic materials. Angle Orthod 1976; 46:196-205.

- Baty DL, Storie DJ, Fraunhofer JA. Synthetic elastomeric chains: a literature review. Am J Orthod Dentofac Orthop 1994; 10:536-542.

- Young J, Sandrik JL. The influence of preloading on stress relaxation of orthodontic elastic polymers. Angle Orthod 1979; 49:104-109.

- Chang HF. Effects of instantaneous prestretching on force degradation characteristics of orthodontic plastic modules. Proc Natl Sci Counc Repub China 1987; 11:45-53.

- Brooks DG, Hershey HG. Effects of heat and time on stretched plastic orthodontic modules [abstract]. J Dent Res 1976; 55:363.

- Brantley WA, Salander S, Myers CL, Winders RV. Effects of prestretching on force degradation characteristics of plastic modules. Angle Orthod 1979; 49:37-43.

- de Aguiar, Adelson Mota, et al. The prestretching effect on the force decay of orthodontic elastic chain. J Contemporary Dent Practice 2014; 15:456-460.

- Kulshrestha, Rohit S, Tandon R, et al. Canine retraction: A systematic review of different methods used. J Orthodont Sci 2015; 4:1.

- Gioka C, Zinelis S, Eliades T, et al. Orthodontic latex elastic: A force relaxation study. Angle Orthod 2006; 76:475-479.

- Howard Robert S, Robert J Nikolai. On the relaxation of orthodontic elastic threads. Angle Orthodont 1979; 49:167-172.

- Lu, Tz Chau, et al. Force decay of elastomeric chain-A serial study. Part II. Am J Orthodont Dent Orthop 1993; 104:373-377.

- Russell KA, Milne AD, Khanna RA, et al. In vitro assessment of the mechanical properties of latex and non-latex orthodontic elastics. Am J Orthodont Dentofac Orthop 2001; 120:36-44.

- Santos AC, Tortamano A, Naccarato SR, et al. An in vitro comparison of the force decay generated by different commercially available elastomeric chains and NiTi closed coil springs. Br Oral Res 2007; 21:51-57.

- Balhoff DA, Shuldberg M, Hagan JL, et al. Force decay of elastomeric chains–A mechanical design and product comparison study. J Orthodont 2011; 38:40-47.

- Mohammed, Nibras J, Mushriq F Al-Janabi. Force decay of orthodontic elastomeric chains by using three different mechanisms simulating canine retraction. J Baghdad College Dent 2013; 25:159-163.

- Abdullah NN, Ghaib NH. An evaluation the effect of alcohol presence in mouth washes on force degradation of different configurations of elastomeric chains. J Baghdad College Dent 2016; 28:134-138.

Author Info

Safa Munir Abdulsattar* and Iman I Al-Sheakhli

Department of Orthodontics, College of Dentistry, University of Baghdad, Baghdad, IraqCitation: Safa Munir Abdulsattar, Iman I Al-Sheakhli, Effect of Different Prestretchings on Force Decay of Synthetic Orthodontic Elastomeric Modules at Different Time Intervals (An In vitro Study), J Res Med Dent Sci, 2020, 8 (7): 400-406.

Received: 21-Oct-2020 Accepted: 10-Nov-2020 Published: 17-Nov-2020