Research - (2021) Volume 9, Issue 4

Development and Assessment of a New Bioactive Glass Fiber Post Part I: Flexural Strength and Fatigue Resistance

Akram Altamimi M* and Manhal Majeed A

*Correspondence: Akram Altamimi M, Department of Restorative and Esthetic Dentistry, College of Dentistry, Baghdad University, Iraq, Email:

Abstract

Objectives: This study was designed to develop and assess the mechanical properties of an experimental bioactive glass fiber post by the reinforcement of bioactive cement.

Study Design: An in vitro study.

Material and Methods: surface treated unidirectional E-glass fiber were impregnated and implanted with a triple cure, self-adhesive ACTIVA Bioactive resin cement to fabricate an experimental bioactive glass fiber post using hand lay-up molding technique and clear cylindrical split mold with a 2mm diameter. Each specimen ensures 3min for self-cure setting, then light-cured for the 40s. The cylindrical shape post specimens (n=8) were prepared at room temperature for one day before subjected to fatigue test, A custom made three-point bending machine, loading at 90° angle and a frequency of 2 Hz was utilized for fatigue test. The machine was set for two million cycles or until failure of the fiber post. The results were compared with the EXACTO post.

Statistical analysis used: Statistical analysis performed by independent variable t-test performed by using IBM-SPSS program version 22.

Results: Statistically increased flexural strength was recorded of experimental material compared to the virgin Active Bioactive. The flexural fatigue test revealed statistically significant differences between the two posts. The experimental post performed better than EXACTO post.

Conclusions: Reinforcement of the bioactive cement comprises rubberized ionic resin was enhanced flexural strength with a promising modulus of elasticity and exhibited a higher fatigue resistance, suggesting its possibility as new bioactive post material.

Keywords

Dental post, Bioactive, Fiber-reinforced composite, Fatigue resistance.

Introduction

Extensive coronal structure damage and endodontic treatment can frequently weaken the endodontic ally treated teeth [1]. Most of these teeth could not be retained without a little extra support, notably when the horizontal loss of the clinical crown was reported. If the minimum thickness of the ferrule is not adequate to accommodate the residual tooth structure, the post-core build-up following root canal care can be helpful in preserving and facilitating the final reconstruction of the tooth [2]. The demands for tooth-colored dental posts were rising in the last twenty years, so traditional metal posts are regularly being changed by a variety of aesthetic non-metallic posts, which are fabricated by reinforcement of the epoxy resin or methacrylate resin with carbon, quartz or glass fibers, other types include zirconia, ultrahigh molecular weight polyethylene (UHMWPE) or aramid (Kevlar) fiber-reinforced composite posts are differentiated [3,4]. While laboratory studies have shown favorable mechanical and physical properties of fiber posts, clinically, a wide range of failures mechanisms is reported in the literature. Longitudinal clinical studies stated a relatively high failure rate regarding the fiber post restorations [5,6], including multitude issues such as adhesive failure, secondary caries, root or post-fracture, and recurrence of endodontic lesions [7]. Previous glass fiber post studies showed a failure rate of 12.8% for two years [8], 14.1% after five years [5], 9.8% after seven years [9] and A high failure rate of 46% after ten years [6]. Barfeie et al. reported adhesive failure in 16 of the 19 clinical trials, making it the most frequent failure source [7]. They attributed these failures to the components from which the post-core system is fabricated especially the resin matrix, the difference in mechanical properties with dental tissue, inappropriate construction or restorative technique and differences in fiber and matrix properties produce stresses at the fiber-matrix interface, transiting through the fibers' surfaces while the fiber posts are in function [4]. Also, longitudinal research have indicated that the lower elastic module eliminates the root fracturing, but increases the risk of deboning with the subsequent bacterial micro leakage [5].Usually, factors such as volume fraction, proportion of the fibers impregnated in the matrix resin, the orientation of the fibers, the adhesive between the matrix and the fibers, the polymerization shrinkage of the resin, and the individual properties of the matrix and the fibers are contributing to the mechanical strength of the fiber posts. [10]. In fiber-reinforced composite posts, the matrix may be either thermoset (cross linked) or thermoplastic (linear). The most applied matrices in FRC posts are the cross-linked ones, including multifunctional or methacrylate resins such as epoxy resin and glycidyl methacrylate (BISGMA), and biphenyl A- urethane di-methacrylate (UDMA). Although thermosetting polymers with extremely cross linked networks are better than thermoplastics in mechanical properties, thermal stability, and chemical resistance demonstrate inadequate surface adhesive properties [4,11]. These polymers cannot be easily integrated with the resin matrix of the luting cement or core buildup materials. As a result, it is challenging to achieve enough bond with the thermosetting matrix of fiber-reinforced composite posts without surface treatment [4,11]. New restorative dental materials with the bioactive property have been introduced recently. These composites can chemically remineralize enamel and dentin lesions and attach to the living tissue by creating a hydroxyapatite coating at the tooth-material interface that increases the durability of the restoration and avoids bacterial invasion. [12]. The mechanical properties and bond strength can be strengthened by dental restorative materials with bioactive properties, depending on the dissolution of ions from its surface and its microstructure morphology, enhancing the toughening process, crack deflection and bridging [13]. Active Bioactive is a modern type of dental bioactive restorative, its available as base/liner, restorative, cement and fissure sealant. The material composed of a high molecular weight polyacrylic acid, Urethane dimethacrylate monomers, dimethacrylate phosphate (acids), Fluoro-alumino-silicate glass, silanated nonreactive fillers, water, initiators (chemical and light)[14-16].This formulation provided the ionic resilient resin matrix with energy-absorbing elastomeric components (Embrace) which improves its resistance to fracture, wear, and marginal chipping, making it more appropriate in higher stress-bearing areas that are contraindicated for GICs and RM-GIC, this formulation also produces bioactive and ions release-recharge properties [16-18]. Higher fracture toughness was found as compared to compomers and RMGIC [16].Replacing the epoxy or methacrylate resin that utilized in commercial fiber posts by the resilient resin of ACTIVA Bioactive (Embrace resin) and applied such post with the identical cement composition material could be advantageous for the adhesion to the post-cement-dentine system through improved chemical compatibility of post surface with the dental cement by forming a monoblock and enhance physical properties similar to that of tooth structure.

The purpose of this study was to develop a new bioactive glass fiber post using ACTIVA Bioactive cement as a resin reinforced with E-glass fiber and testing the flexural strength and fatigue of the experimental fiber post as compared with one of the commercially available dental post (EXACTO fiber post).

Materials and Methods

Fabrication of the experimental specimens. The fabrication procedure started with the surface treatment for the E-glass fiber (Mayitr Company, China). Unidirectional E-glass fibers bundles with 8-15μm filament diameter and 2,58 g/cm3 density which their chemical composition mention (Table1) was treated with 99.9% acetic acid (Chem-Lab NV, Belgium) for 2h at 55 °C, washed three times with purified water and dried in the incubator. (Sirocacrossline, China) for 8 h at 50°C. A portion of the glass fiber processed with acetic acid was further subjected to wet salination using 2% of 3-methacryloxyproyltrimethoxysilane silane coupling agent A-174 (Sigma-Aldrich, Germany) in a combination of ethanol and water (90/10 w/w) acidified to pH 3.8 and preserved at this level using glacial acetic acid. The glass fiber was preserved in this solution for 1 h and then dried at 110°C for 2 h before using treated glass fiber as in previous studies [3, 19, 20]. The fiber’s surface texture and morphology were examined by scanning electron microscopy (TESCAN VEGA III, TESCAN, Czech Republic) at 5KeV acceleration voltage and magnification (1Kx, 2Kx, and 5Kx). Untreated glass fiber was used as a reference. For the flexural strength test, bar-shaped specimens (n=8) were prepared by the incorporation of one bundle of treated glass fiber (25 mm in length) consisting of a subset of 1000 filaments with a constant amount of ACTIVA Bioactive cement (Pulp dent Corporation, Watertown, USA.) Using polytetrafluoroethylene (PTFE) mound with a bar-shaped (2 mm X 2 mm X 25 mm) designed according to ISO10477.The fiber amount in percentage volume was calculated using the formula. [3,19,21].

| Maerial | Manufacturer | Composition | Batch |

| E-glass fibre | Mayitr company, China | 55%SiO2, 11%Al2O3, 6%B2O3, 18%CaO, 5%MgO, 5%Other | 13723 |

| ACTIVA BioACTIVE Cement | Pulpdent Corporation, Watertown, MA USA | Blend of diurethane and other methacrylates with modified polyacrylic acid. 47 wt% Bioactive glass and sodium fluoride | 180129 |

| EXACTO fiber post | Angelus, Londrina, PR, Brazil | 80% glass fiber and epoxy resin (20%) | 9137 |

Table 1: Composition of the materials used in this study.

Vk(%)= (Ds-Dr)/(Df-Dr) x 100 (Equation 1).

Where ���� is the vol.% of the GF, ���� is the density of the FRC sample, ���� is the GF density (2,58 g/ cm3) and ���� is the density of resin matrix. The fibre content in percentage volume for each sample was 40%.The impregnation procedure of the fiber to resin cement base on hand layup moulding technique that fallow by previous studies [3,22], in which the PTFE mould fixed to a glass slide and Mylar strip, then the resin cement and the treated fiber added and painting layer by layer until the mold filling.

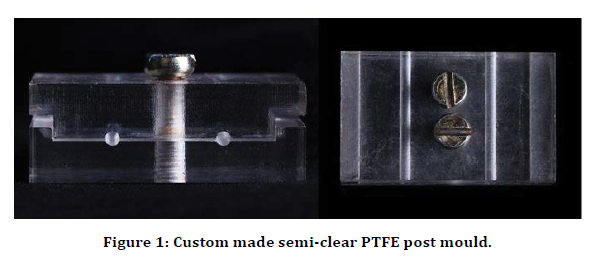

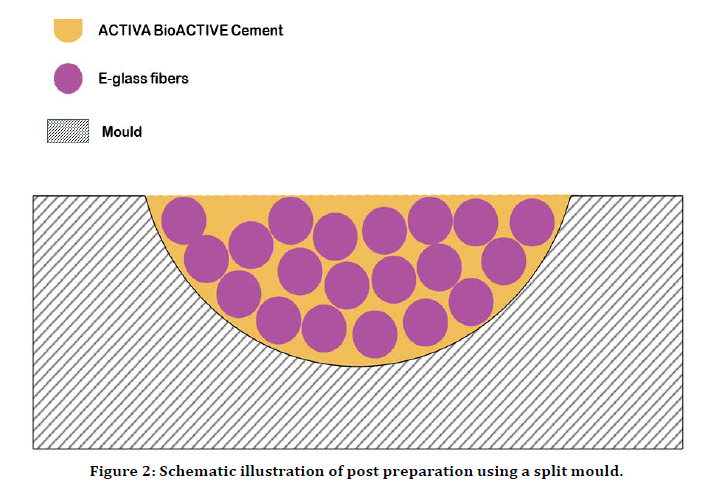

Later, another mylar strip and glass slide were positioned over the mould and pressed with (1 Kg) weight to level up the specimen surface to prevent the formation of bubbles and an oxygen-inhibited layer. Each specimen waiting for 3 minutes to ensure self-cure setting, then cured with visible light for the 40s from Each side of it with Paradigm™ DeepCure L.E.D. (3m, USA.) curing light according to manufacture instruction. Specimens were polished with a silicon carbide paper (grit 800 and 1200). The length, width and thickness of each specimen were then verified with a digital caliper. These specimens were then kept at room temperature for 24 hours prior to the three-point bending examination. [3, 19]. Eight specimens of virgin ACTIVA Bioactive without glass fiber were prepared as reference samples. For the flexural fatigue test, experimental posts with cylindrical parallel shape (n=8) were prepared following the same procedure and utilizing specially design custom made semi-clear PTFE with a cylindrical shape center hallow (20mm in length and 2mm in diameter) carried out according to ISO 10477 forming by two parts join tightly by two closing screws (Figure 1). Schematic illustration (Figure 2) demonstrated the preparation of experimental post using the split mould. EXACTO fiber post (Angelus, Londrina, Brazil) applied as a commercial reference.

Figure 1. Custom made semi-clear PTFE post mould.

Figure 2. Schematic illustration of post preparation using a split mould.

Flexural properties measurement

According to ISO 10477 specifications, a threepoint bending test was carried out at a crosshead pace of 1 mm/min using a 3 mm metal rod in diameter with a loading angle of 90 ° and a span length of 20 mm in a computer-controlled universal testing machine (Tinius Olsen, Model 25 ST).Using Eqs (2) and (3), flexural strength (σ) was measured in MPa and flexural modulus (E) in GPa., respectively.

Q=3FL/2bh2 (Equation 2).

E=L3/4bh3 x F/Y (Equation 3).

Where F =maximum strength, b=width of the specimen, L=distance between the rests, h = height of the specimen, and F/Y = The slope of the stress-strain curve's linear component [3,23,24].

Flexural Fatigue measurement

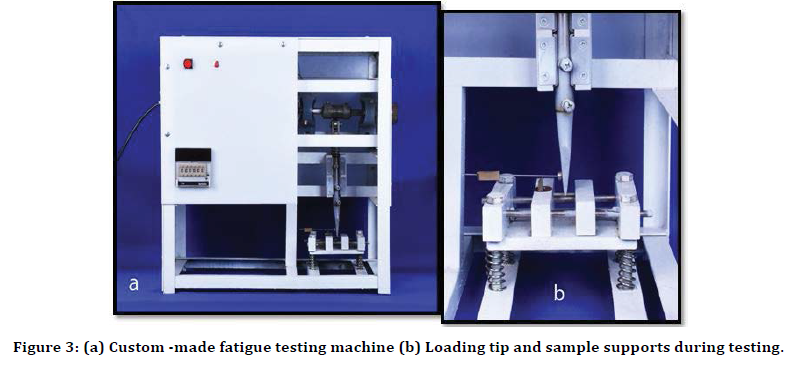

The flexural fatigue test was done using a custom -made fatigue testing machine. This machine was assembled and manufactured according to the design and calibration of a device manufactured by (Bose, ElectroForce® System, MN, USA). This device has a counter that calculates the number of cycles with default regulation for the number of loads cycles and stops when the specimen falls (Figure 3). The cross-sectional diameter of the loading tip was 3mm and extreme supports at 20 mm with adjustable control. A loading Angle of 90° with a frequency of 2 Hz was carried out at three points bending test until the sample failed or broken. The fatigue machine designed with pre-set load at approximately 50% of both posts' static flexural load, approximately 60N [3,25,26]. The span length was fixed at 10mm. The fatigue test was performed at a room temperature of almost 25 ° C. The machine was set to take out 2 x 106 cycle and the definite number of resisted cycles until failure was calculated by machine [3, 25-27]. The recorded data statistically analyzed with independent variable t-test performed at the level of significance of 0.05.

Figure 3. (a) Custom -made fatigue testing machine (b) Loading tip and sample supports during testing.

Results

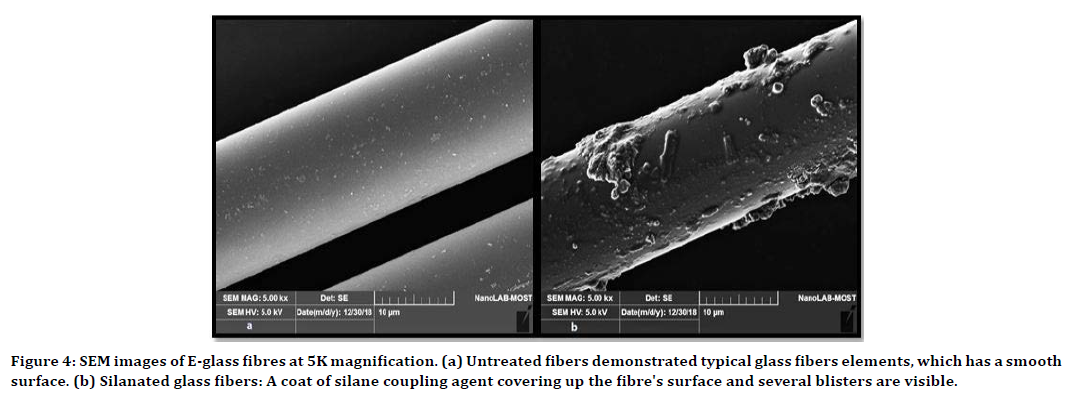

Glass fiber surface modification. The micrograph for the surface morphology of the E-glass fibres proved by scanning electron microscopy that the untreated fibers (Figure4A) had a smooth texture whereas the silanated fibres (Figure 4B) seemed to be etched with a rough surface and a clear salinization blisters.

Figure 4. SEM images of E-glass fibres at 5K magnification. (a) Untreated fibers demonstrated typical glass fibers elements, which has a smooth surface. (b) Silanated glass fibers: A coat of silane coupling agent covering up the fibre's surface and several blisters are visible.

Flexural properties

Statistically increased flexural strength was recorded in the experimental group (598.08 ± 20.72 MPa) compared to the virgin ACTIVA BioACTIVE group (86.39 ± .202 MPa). Regarding the flexural modulus, there is a higher significant increase in the experimental group (15.79± .584 GPa) as compared to the virgin material (2.42 ± .021GPa). Independent student’s t-test recorded a highly significant difference between the two groups regarding the flexural strength and the flexural modulus (Table.2).

| Property | Material | N | Minimum | Maximum | Mean | Std. Deviation | t-test | p-value |

|---|---|---|---|---|---|---|---|---|

| Flexural strength | Experimental | 8 | 576.4 | 633.5 | 598.08 | 20.72 | 69.83 | 0.001HS |

| Virgin ACTIVA | 8 | 86.11 | 86.74 | 86.39 | 0.202 | |||

| Flexural modulus | Experimental | 8 | 15.09 | 16.53 | 15.79 | 0.584 | 64.59 | 0.000HS |

| Virgin ACTIVA | 8 | 2.41 | 2.47 | 2.42 | 0.021 |

Table 2: Descriptive statistic and Student’s t-test for comparison of the flexural strength (MPa) and flexural modulus (GPa) of the experimental and virgin material.

Fatigue test

It is clear that the experimental post was documented the highest mean value of cycle before failure (1.9 x 105), whilst the EXACTO fiber post was recorded a mean value of about (1.3 x 105) preceding failure. The comparison of significance revealed a statistically significant effect on the type of post material on the flexural fatigue of the two different post samples (Table 3).

| Post type | N | Minimum | Maximum | Mean | SD | t.test | p.value |

|---|---|---|---|---|---|---|---|

| Experimental Post | 8 | 1970820 | 1990850 | 1980680 | 7523.34 | -85.94 | 0.000HS |

| EXACTO post | 8 | 1330240 | 1380840 | 1350572 | 19325.07 | ||

| Significantly different (P≤ 0.05) | |||||||

Table 3: Student’s t-test for comparing the significance of the flexural fatigue cycles mean of the two groups.

Discussion

The justification behind the usage of ACTIVA Bioactive as a resin matrix, That the material, create a mixture of diurethane and methacrylate monomers with enhanced polyacrylic acid and polybutadiene modified diurethane dimethacrylate (Embrace resin) referred to as synthetic rubberized resin [17, 28]. These introductions of monomers are alleged to convey durability to the substance that enhanced its tolerance to fracture, wear, and chipping. The deficiency of the chemical adhesion between the methacrylate-based composite resin matrix and the epoxy resin matrix of the fiber matrix is the major source of post-composite bond fragility. [29].The use of recently developed dual-cure or self-curing cement in fibre posts, cementation is advocated to achieve polymerization in deep regions [30]. The construction of the dental fiber post from the matching resin cement material may resolve the complications of adhesion [29] and offered a monoblock system that provides better stress distribution and retention of the final restoration [31] combined with a bioactive property which might decrease recurrent caries and micro leakage[32] and preserve the durability of the adhesion [33,34].Along with bioactivity and ion-releasing property of ACTIVA Bioactive, its contain urethane-dimethacrylate monomer (UDMA), which provided advantages of its easy preparation and adequate working time after light exposure [35]. Besides, the UDMA has a high viscosity and excellent mechanical properties as homopolymer, make it the only dimethacrylate that be able to be utilized alone in commercial composites such as Lava Ultimate® (3M ESP) [36]. ACTIVA Bioactive may be a suitable choice resin matrix for the fabrication of bioactive dental post. Literature and patent research were showed no report on fiber reinforced composite post with bioactive and ions release property, and we can consider our study as the first trailer for fabricated such post. The fibres' boosting ability varies with the quantity, orientation, fiber impregnation with resin matrix and adhesion of the fibers to the resin [37].Different fibers have high efficiency, but in dental applications, glass fibers tend to be the fibers of preference since silanated glass fibers have superior adhesion to methacrylates [38], adding to excellent esthetic properties. Several studies have confirmed the relationship concerning the quantity of fibers in the resin matrix and the development of the flexural and impact strength of fiber-reinforced composite prosthesis [39-41].The composites' flexural strength improved with the acetic acid-treated fibre, as the mechanical meshing induced by the surface micro-roughness of the etching fiber [42]. As a consequence, E-glass fibers used in reinforcement are basically pre-treated with a coupling agent, reacting with both organic polymer resin and inorganic oxide substrate. The most used coupling agents (Trialkoxysilanes) utilized in this study comprise organic groups corresponding with the polymer resin. This silane can reduce the stress of thermal cycling at the interface and improved the water-resistance of the reinforced composite [20, 43]. For hand lay-up moulding technique or manually adapted fibers for reinforcement were utilized in various studies with different specimen preparation techniques, fiber types, fiber wetting, and fiber loading in the mould [44, 45]. In this study, the fiber loading of 40% w was calculated by a formula that mentions by Abdulmajeed et al. which reported that “When the fiber matter in the resin composite increases, the strength and modulus of elasticity of this composite also increase” [21]. The results of the three-point bend test revealed a significantly greater fracturing load for the experimental material as compared to the virgin ACTIVA BioACTIVE material, besides, the flexural strength of the experimental material was comparable to the flexural strength of the commercially available glass fiber posts, as the flexural strength of the various commercially available fiber posts in the market were evaluated by different studies [3,23,46-48], which have been reported that flexural strength of the glass fiber post in the range of 453-936 MPa [4,10]. Different studies were reported that the addition of UDMA into copolymers caused a rise in both tensile and flexural strength. It confirmed that physical crosslinks are more important than their strength [49, 50]; this may explain the higher flexural strength of the experimental material. Adding to that, Unidirectional fibers used in this study may effectively reinforce ACTIVA resin when positioned in one direction, as the unidirectional glass fiber reinforced composite has comparative stiffness and strength to metal when loading in long axis to the fibers, but with much less weight device [21,48,51]. Regarding flexural modulus (Young's modulus) that recorded for the experimental group (15.79 ± 0.5) GPa can be considered too close to Young's modulus of the dentine (12.8-13.6) GPa [41,52- 54], Such modulus of elasticity has identical physical properties of the fiber post to those of natural dentin with relatively even form of stress distribution [55]. The resilient resin matrix with energy-absorbing elastomeric components (embrace resin) of ACTIVA could explain the high flexural modulus value after reinforcement with glass fiber [16,56]. The usual occlusal and chewing mechanism between natural and restored teeth is subject to cyclic loading on a regular basis, the present study compares the Experimental and EXACTO posts regarding the cycling fatigue failure as a clinically relevant testing method [25]. In this study, a constant load of 60 N was applied at a frequency of 2 Hz and the loading device was maintained in steady contact with the specimen. In fatigue studies, the force applied should not exceed 50 percent of the ultimate static load strength. To simulate approximately four years of regular occlusion and masticatory operation, the number of cycles was set at two million cycles. The teeth typically come in contact one a minute. All these setting was fallow with previous studies [25,48,57].The findings of the cyclic fatigue test differ with the L/D ratio (ratio between post span length and diameter) of the analysis set-up and should be clarified with notice. [24]. The L/d ratio utilized in this study was approximately 5, according to a span distance of 10 mm and a diameter of 2 mm in engineering material standard ASTMD 2344 for the short beam test, indicating an L/d ratio of no less 4 to evaluate the interlaminar shear strength of the material. [46]. Regarding fatigue failure, the experimental post recorded the higher mean value of cycles before failure compared to EXACTO post with a statistically significant difference. Such a result may be related to the differences in the chemical composition of both post type. EXACTO fiber post matrix is composed of the epoxy resin. In contrast, the experimental post was composed of methacrylate resin with intermediate degree of conversion and strongly crosslinked structure which may influence the mechanical properties of the experimental post [24, 57], this result agreed with previous studies by Grandini et al. which reported that the resin matrix could eventually play in important role in fatigue failure of the post and “The stress performs on the matrix mainly when a compressive force is applied on the post or once the forces are pointed obliquely to the longitudinal axis of the post” [25] Another study by Soares et al. reported that methacrylate matrix experiences more stress as a result of Its stiffer form than the epoxy matrix. [58].So if the resin matrix is less prone to tensile strain, plastic deformation of the resin micro cracking happens and fractured [4,59]. Zicari et al. reported that the “flexural strength of fiber post is not linked to the structural characteristics but may instead be influenced by the resin matrix's mechanical properties and the adhesion between fibers and matrix” [24].In addition, ACTIVA BioACTIVE cement includes a proprietary of resilient resin matrix with energyabsorbing elastomeric components (Embrace), such components may introduce a benefit by providing a resin matrix material more resilient against impact forces with high toughness, helps the resin absorb mastication load and other forces by providing adequate strength and durability to the dental prosthesis [16,17,60]. Another imperative factor that may affect the fatigue result is whether the glass fibers are silanated before implanting in the resin matrices or not. Good salination contributes to correct interfacial bonding, ensuring load transition across the matrix [25,61]. Owing to the variation between the fiber elasticity modulus and the matrix, high tension on the fiber/resin interface is responsible for continuous inelastic output arising from the detachment of the interface between the fibers and the matrix. [59,62]. The combination of the construction process with the fibre's salinization before embedding and subsequent chemical bonding with the resin matrix may explain the preference of the experimental post over the EXACTO. Much of this EXACTO data, however, is manufacturing secrets. This result corroborates previous findings, showing that flexural properties differ depending on post brand [24,41,61,63]. It is worth to mention that the recorded data of the flexural fatigue test are higher than what clinically may happen as cement failure may occur before post-failure [25].

Conclusion

• The reinforcement of the ACTIVA Bioactive cement with E-glass fiber enhanced the flexural strength with promising flexural modulus.

• The experimental post exhibits higher fatigue resistance, suggesting its possibility as a new bioactive fiber post.

Acknowledgements

The authors deny any conflict of interests related to this study. The authors would like to thank Dr Ahmed Almaroof (Assistant Professor at Department of Restorative and Esthetic Dentistry, College of Dentistry, Baghdad University) for all his support and advice during the preparation period for this study.

References

- Shahrbaf S, Mirzakouchaki B, Oskoui SS, et al. The effect of marginal ridge thickness on the fracture resistance of endodontically-treated, composite restored maxillary premolars. Operative Dent 2007; 32:285-90.

- Mannocci F, Cowie J. Restoration of endodontically treated teeth. Br Dent J 2014; 216:341-346.

- Almaroof A, Ali A, Mannocci F, et al. Semi-interpenetrating network composites reinforced with Kevlar fibers for dental post fabrication. Dent Materials J 2019: 26:38:511-21.

- Lamichhane A, Xu C, Zhang FQ. Dental fiber-post resin base material: a review. J Adv Prosthodont 2014; 6:60.

- Parisi C, Valandro LF, Ciocca L, et al. Clinical outcomes and success rates of quartz fiber post restorations: a retrospective study. J Prosthetic Dent 2015; 114:367-372.

- Naumann M, Koelpin M, Beuer F, et al. 10-year survival evaluation for glass-fiber–supported postendodontic restoration: A prospective observational clinical study. J Endodont 2012; 38:432-435.

- Barfeie A, Thomas MB, Watts A, et al. Failure mechanisms of fibre posts: A literature review. Eur J Prosthodont Restorative Dent 2015; 23:115-27.

- Naumann M, Blankenstein F, Dietrich T. Survival of glass fibre reinforced composite post restorations after 2 years: An observational clinical study. J Dent 2005; 33:305-312.

- Cloet E, Debels E, Naert I. Controlled clinical trial on the outcome of glass fiber composite cores versus wrought posts and cast cores for the restoration of endodontically treated teeth: A 5-year follow-up study. Int J Prosthodont 2017; 1:30.

- Drummond JL, Bapna MS. Static and cyclic loading of fiber-reinforced dental resin. Dent Materials 2003; 19:226-231.

- Yan L, Chouw N, Jayaraman K. Flax fibre and its composites–A review. Composites Part B: Engineering 2014; 56:296-317.

- Khan AS, Ahmed Z, Edirisinghe MJ, et al. Preparation and characterization of a novel bioactive restorative composite based on covalently coupled polyurethane–nanohydroxyapatite fibres. Acta Biomater 2008; 4:1275-1287.

- Schumacher GE, Antonucci JM, O'Donnell JN, et al. The use of amorphous calcium phosphate composites as bioactive basing materials: Their effect on the strength of the composite/adhesive/dentin bond. J Am Dent Assoc 2007; 138:1476-1484.

- Francois P, Fouquet V, Attal JP, et al. Commercially available fluoride-releasing restorative materials: A review and a proposal for classification. Materials 2020; 13:2313.

- Huang CT, Blatz MB, Arce C, et al. Inhibition of root dentin demineralization by ion releasing cements. J Esthetic Restorative Dent 2020; 32:791-796.

- Garoushi S, Vallittu PK, Lassila L. Characterization of fluoride releasing restorative dental materials. Dent Mater J 2018; 30:2017-161.

- Pameijer CH, Garcia-Godoy F, Morrow BR, et al. Flexural strength and flexural fatigue properties of resin-modified glass ionomers. J Clin Dent 2015; 26:23-27.

- van Dijken JW, Pallesen U, Benetti A. A randomized controlled evaluation of posterior resin restorations of an altered resin modified glass-ionomer cement with claimed bioactivity. Dent Mater 2019; 35:335-343.

- Furtos G, Baldea B, Silaghi-Dumitrescu L. Development of new radiopaque glass fiber posts. Materials Sci Eng 2016; 59:855-862.

- Matisons JG. Silanes and siloxanes as coupling agents to glass: a perspective. InSilicone Surface Science 2012; 281-298.

- Abdulmajeed AA, Närhi TO, Vallittu PK, et al. The effect of high fiber fraction on some mechanical properties of unidirectional glass fiber-reinforced composite. Dent Mater 2011; 1;27:313-21.

- Park SJ, Seo MK. Element and processing. InInterface science and technology 2011; 431-499.

- de la Peña VA, Darriba IL, Valea MC, et al. Mechanical properties related to the microstructure of seven different fiber reinforced composite posts. J Adv Prosthodont 2016; 8:433.

- Zicari F, Coutinho E, Scotti R, et al. Mechanical properties and micro-morphology of fiber posts. Dent Mater 2013; 29:e45-52.

- Grandini S, Goracci C, Monticelli F, et al. Fatigue resistance and structural characteristics of fiber posts: three-point bending test and SEM evaluation. Dent Mater 2005; 21:75-82.

- Matheus TC, Kauffman CM, Braz AK, et al. Fracture process characterization of fiber-reinforced dental composites evaluated by optical coherence tomography, SEM and optical microscopy. Br Dent J 2010; 21:420-427.

- Rosentritt M, Behr M, Preis V. A critical evaluation of fatigue studies for restorative materials in dentistry. Current Oral Health Reports 2016; 3:221-228.

- Bansal R, Burgess J, Lawson NC. Wear of an enhanced resin-modified glass-ionomer restorative material. Am J Dent 2016; 29:171-1744.

- Monticelli F, Osorio R, Sadek FT, et al. Surface treatments for improving bond strength to prefabricated fiber posts: A literature review. Operative Dent 2008; 33:346-355.

- Mainardi MD, Giorgi MC, Lima DA, et al. Effect of energy density and delay time on the degree of conversion and Knoop microhardness of a dual resin cement. J Investig Clin Dent 2015; 6:53-58.

- Tay FR, Pashley DH. Monoblocks in root canals: A hypothetical or a tangible goal. J Endod 2007; 33:391-398.

- Kaushik M, Yadav M. Marginal microleakage properties of activa bioactive restorative and nanohybrid composite resin using two different adhesives in non-carious cervical lesions-an in vitro study. J West African College Surgeons 2017; 7:1.

- Jefferies SR, Pameijer CH, Appleby D, et al. One year clinical performance and post-operative sensitivity of a bioactive dental luting cement. Swed Dent J 2009; 33:193-9.

- Sauro S, Makeeva I, Faus-Matoses V, et al. Effects of ions-releasing restorative materials on the dentine bonding longevity of modern universal adhesives after load-cycle and prolonged artificial saliva aging. Materials 2019; 12:722.

- Singh AV, Ansari MH, Laux P, et al. Micro-nanorobots: Important considerations when developing novel drug delivery platforms. Expert Opinion Drug Delivery 2019; 16:1259-1275.

- El-Banna A, Sherief D, Fawzy AS. Resin-based dental composites for tooth filling. Adv Dent Biomater 2019; 1:127-173.

- Vallittu PK. Glass fiber reinforcement in repaired acrylic resin removable dentures: Preliminary results of a clinical study. Quintessence Int 1997; 1:28.

- Vallittu PK. Curing of a silane coupling agent and its effect on the transverse strength of autopolymerizing polymethylmethacrylate—glass fibre composite. J Oral Rehab 1997; 24124-24130.

- Novais VR, Versluis A, Correr‐Sobrinho L, et al. Three‐point bending testing of fibre posts: Critical analysis by finite element analysis. Int Endod J 2011; 44:519-524.

- Asmussen E, Peutzfeldt A, Heitmann T. Stiffness, elastic limit, and strength of newer types of endodontic posts. J Dent 1999; 27:275-278.

- Lassila LV, Tanner J, Le Bell AM, et al. Flexural properties of fiber reinforced root canal posts. Dent Mater 2004; 20:29-36.

- Almaroof AG. Polymer composites for restoration of endodontically treated teeth. Doctoral dissertation, King's College London.

- Brook MA. Silicon in organic, organometallic, and polymer chemistry. 2000; 704.

- Behr M, Rosentritt M, Lang R, et al. Flexural properties of fiber reinforced composite using a vacuum/pressure or a manual adaptation manufacturing process. J Dent 2000; 28:509-514.

- Lassila LV, Nohrström T, Vallittu PK. The influence of short-term water storage on the flexural properties of unidirectional glass fiber-reinforced composites. Biomaterials 2002; 23:2221-2229.

- Novais VR, Rodrigues RB, Simamoto PC, et al. Correlation between the mechanical properties and structural characteristics of different fiber posts systems. Brazilian Dent J 2016; 27:46-51.

- Zicari F, Coutinho E, Scotti R, et al. Mechanical properties and micro-morphology of fiber posts. Dent Mater 2013; 29:e45-52.

- Hattori M, Takemoto S, Yoshinari M, et al. Durability of fiber-post and resin core build-up systems. Dent Mater J 2010; 29:224-228.

- Pfeifer CS, Silva LR, Kawano Y, et al. Bis-GMA co-polymerizations: Influence on conversion, flexural properties, fracture toughness and susceptibility to ethanol degradation of experimental composites. Dent Mater 2009; 25:1136-1141.

- Barszczewska-Rybarek IM. Structure–property relationships in dimethacrylate networks based on Bis-GMA, UDMA and TEGDMA. Dent Mater 2009; 25:1082-1089.

- Dyer SR, Lassila LV, Jokinen M, et al. Effect of fiber position and orientation on fracture load of fiber-reinforced composite. Dent Mater 2004; 20:947-955.

- Kinney JH, Marshall SJ, Marshall GW. The mechanical properties of human dentin: a critical review and re-evaluation of the dental literature. Crit Rev Oral Biol Med 2003; 14:13-29.

- Bateman G, Ricketts DN, Saunders WP. Fibre-based post systems: A review. Br Dent J 2003; 195:43-48.

- Novais VR, Quagliatto PS, Della Bona A, et al. Flexural modulus, flexural strength, and stiffness of fiber-reinforced posts. Indian J Dent Res 2009; 20:277.

- Goracci C, Ferrari M. Current perspectives on post systems: A literature review. Australian Dent J 2011; 56:77-83.

- Abdulla HA, Majeed MA. Assessment of bioactive resin-modified glass ionomer restorative as a new CAD/CAM material part II: Fracture strength study. J Res Med Dent Sci 2019; 7:74-79.

- Ferrari M. A retrospective study of fiber-reinforced epoxy resin posts vs. cast posts and cores: A four year recall. Am J Dent 2000; 13:B9-14.

- Soares CJ, Santana FR, Pereira JC, et al. Influence of airborne-particle abrasion on mechanical properties and bond strength of carbon/epoxy and glass/bis-GMA fiber-reinforced resin posts. J Prosthet Dent 2008; 99:444-454.

- Grandini S, Balleri P, Ferrari M. Scanning electron microscopic investigation of the surface of fiber posts after cutting. J Endod 2002; 28:610-612.

- Abdulla HA, Majeed MA. Assessment of bioactive resin-modified glass ionomer restorative as a new CAD/CAM material part II: Fracture strength study. J Res Med Dent Sci 2019; 7:74-79.

- Seefeld F, Wenz HJ, Ludwig K, et al. Resistance to fracture and structural characteristics of different fiber reinforced post systems. Dent Mater 2007; 23:265-271.

- Eick JD, Smith RE, Pinzino CS, et al. Photopolymerization of developmental monomers for dental cationically initiated matrix resins. Dent Mater 2005; 21:384-390.

- Lassila LV, Vallittu PK. The effect of fiber position and polymerization condition on the flexural properties of fiber-reinforced composite. J Contemp Dent Pract 2004; 5:14-26.

Author Info

Akram Altamimi M* and Manhal Majeed A

Department of Restorative and Esthetic Dentistry, College of Dentistry, Baghdad University, IraqCitation: Akram Altamimi M, Development and Assessment of A New Bioactive Glass Fiber Post. Part I: Flexural Strength and Fatigue Resistance, J Res Med Dent Sci, 2021, 9 (4):16-24.

Received: 09-Feb-2021 Accepted: 29-Mar-2021