Research - (2021) Volume 9, Issue 1

Comparison of First order Loads Deflection Forces of Super-Elastic Nickel Titanium Arch Wires (An In Vitro Study)

Afnan Jamaluddin*, Rasha Y Al-Darzi and Aseel Fadhil Yassin

*Correspondence: Afnan Jamaluddin, Department of Pedodontics, Orthodontics and Preventive Dentistry. College of Dentistry, University of Mosul, Iraq, Email:

Abstract

Aims: to compare the load-deflection ratios between three groups of super elastics nickel-titanium orthodontic wires from three different manufacturers super elastic 0.012-inch wires.

Materials and Methods: the sample examined were 150 nickel-titanium alloy orthodontic wires commercially available from three different manufacturers (IOS, A-star and DENXY super elastics nickel-titanium 0.012 inch wires ) were tested for load deflections rate, the records were taken with the aid of digital Universal testing machine(compression tension machine), simulating an extrusive force at the right canine (TYPODONT model) , in-activations of 0 to 3 mm, with readings of the force released by deflection in unloading of 0.5mm, starting from 2.5mm, 2mm,1.5mm,1mm, 0.5mm consequently.

Results: statistically significant differences were found among the three wire manufactures concerning the load deflections behaviors illustrate that the least mean of wire deflections recorded for the (A star) wire type then followed by (IOS) wire type and the greatest mean was for the (DENXY) wire (A-star<IOS<DENXY) at unloaded distances in a consequence of 0.5mm.

Conclusion: the comparison of mean load-deflection ratios revealed that (A star) wire has the lowest mean load-deflection ratios while (DENXY) wire has the greatest mean value.

Keywords

First order bend, Nickel-titanium wires, Deflection rate, Super elastic nickel-titanium wire, Nickel-titanium arch wire

Introduction

The golden concept and interesting benefits that nickel-titanium alloys have been widely used in comprehensive orthodontic treatment over the past ten years because of their superelasticity and shape memory effects which are favorable mechanical properties [1,2-5]. Nickeltitanium arch wires can be transformed to the austenitic phase from the martensitic crystalline phase by heating, on cooling the reverse process occurs [6-9]. The modulus of elasticity of each orthodontic metal alloy does not change, stainless steel alloys have a high modulus of elasticity which considered to be more rigid in comparison to nickel-titanium alloy, otherwise multiple bends can be applied on stainless steel weirs during different phases of orthodontic treatment to avoid excessive force levels by passing rigidity of the alloy [10]. So, the greater is the modulus of elasticity of a wire, the higher will be the load-deflection ratio and its rigidity [11]. The super elastic exhibit hysteresis (i.e., the activation and deactivation plateaus have different stress magnitudes). as a result, the wire does not deliver the same force as that applied to activate it, The mechanical hysteresis is related to the difference between the loading and unloading stress plateaus where energy is dissipated or absorbed [12]. However, precise bending of these arch wires is difficult and can lead to changes within the crystal structure of the alloy, thus changing the mechanical properties unpredictably [13]. The wire force depends on wire deformation (such as on tooth deviation and (angulation of the tooth) and the wire crosssection and material [14].

The evaluation of load deflection of orthodontic wires has a great importance in all phases of orthodontic treatment and the variance of load deflection of super elastic wires is of practical importance concerning the first stage of treatment. the aim of this study was to investigate the variation of load deflection of super elastic 0.012-inch wires that were commercially available from three different manufacturers (IOS company, DENXY company, A-star company).

Materials and Methods

The sample examined was 150 nickel-titanium alloy orthodontic wires commercially available from three different manufactures IOS, A-star and DENXY super elastic nickel-titanium 0.012-inch wires. the wires tested are mainly available as preformed arches, these were tested for load deflection rate in dry conditions [15], the records were taken with the aid of digital Universal testing machine (Figure 1) (compression tension machine) at department of mechanical engineering)/college of engineering /University of Mosul. For the testing methods, a TYPODONT model (Dentarum, Germany) firmly fixed to the underlying bench with metal screw, full arch attachment bracket set (22 Roth brackets, Dentarum, Germany) attached to teeth of TYPODONT model, except for the maxillary right canine attachment bracket that was fixed to the rod of test machine after removal of canine from the model simulating an extrusive force at the right canine starting from maximum of 3mm loaded position, when the records of loaddeflection were taken at each 0.5mm unloading test, starting from 2.5m, 2mm, 1.5mm, 1mm, 0.5mm consequently (Table 1).

Figure 1. Digital weighing indicator.

| Materials |

| Brackets Roth edgewise conventional stainless-steel brackets (Dentarum, Germany) |

| Bondable buccal tubes (lancer orthodontics, California) |

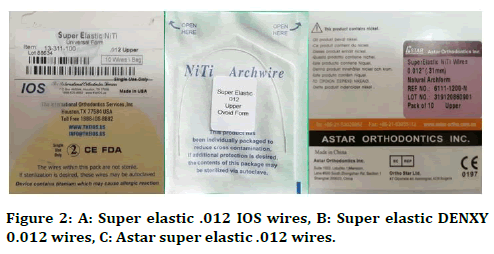

| Arches wires (0.012 inch round preformed arch- super elastic nickel-titanium wires from three different manufactures IOS, A star, DENXY) (Figure 2) |

| Elastic ligatures (Dentaurum, Germany) |

| Universal testing machine (Compression tension machine) |

Table 1: Materials.

Figure 2. A: Super elastic .012 IOS wires, B: Super elastic DENXY 0.012 wires, C: Astar super elastic .012 wires.

Measurement Procedures

The Universal testing machine (compression tension machine) the machine was designed by the department of mechanical engineering / college of engineering /University of Mosul. It consists of electronic compact scale SF-400A for measuring force in gram figure 1. The sensor of the scale was placed out horizontal and vertical rods were attached, metallic base support for vertical measurement stabilized and fixed on the compact scale used for supporting the standard model of teeth that to be tested. Dial gauge for measuring the distance of wire deflection. Dentaurum maxillary orthodontic study model was prepared by removing the right maxillary canine to allow deflection of the wire vertically.

After completing the fixation of brackets and tubes then the model was fixed to the base support at its constant position, inserting a wire in the molar tubes and engage it to the slots of brackets on stabilizing model and to the bracket of missing canine that bonded on the deflecting rod tying the wire to all bracket with ligatures. After completing ligation, the engaged wire was deflected to 3mm vertically at right canine site, the unloading force was recorded at every 0.5mm interval.

The three groups of super elastics nickel titanium orthodontic wires from three different manufactures IOS, A-star and DENXY super elastics nickel titanium 0.012 inch wires were tested for load deflections rate from maximum of 3mm loaded position when the records of load deflection were taken at each 0.5mm unloading test, starting from 2.5mm, 2mm,1.5mm,1mm,0.5mm consequently, the records of the three groups were tabulated and statistically analyzed with the aid of software package SPSS 18,then the mean and standard deviation were calculated, and the analysis of variance (ANOVA at p<0.001) was accomplished to investigate the level of significance among the three wire manufactures concerning the load deflections behaviors weighing the mean for groups using Duncan multiple range test post hock as shown in table 2.

| Distance | Wire brand | No. | Mean | F-value | p-value* | Duncan’s grouping† |

|---|---|---|---|---|---|---|

| 0.5 mm | IOS | 10 | 61.9 | 7.314 | 0.003 | A |

| A-star | 10 | 54.2 | B | |||

| DENXY | 10 | 50 | C | |||

| 1 mm | IOS | 10 | 61.2 | 33.255 | 0 | B |

| A-star | 10 | 48.4 | A | |||

| DENXY | 10 | 71.6 | C | |||

| 1.5mm | IOS | 10 | 50.5 | 105.074 | 0 | B |

| A-star | 10 | 34.1 | A | |||

| DENXY | 10 | 69 | C | |||

| 2 mm | IOS | 10 | 43.1 | 106.184 | 0 | B |

| A-star | 10 | 22 | A | |||

| DENXY | 10 | 63 | C | |||

| 2.5 mm | IOS | 10 | 39.2 | 107.464 | 0 | A |

| A-star | 10 | 18 | A | |||

| DENXY | 10 | 63.8 | B |

Table 2: Descriptive statistics and ANOVA at p<0.001 for the three groups of wires at five distances of unloaded position test.

Result

The descriptive analysis for each group of the three manufacturers illustrate that the least mean of wire deflections recorded for the A-star wire type then followed by the IOS wire type and the greats mean was for the DENXY wire (A-star<IOS<DENXY) at unloaded distances in a consequence of 0.5mm as shown in table 2.

Discussion

The results of the current study were explaining the differences of super elastic wires from different manufacturers in deflection rate recorded on the deactivation force [16]. The super elastic wires have been widely used when large deflections and relatively constant force are required during active stages of tooth movements is needed, the unloading force is of main importance for orthodontic treatment at different phases [8]. These types of wires exhibit magnificent clinical advantages through the application of relatively low and stable force levels for the first phase of treatment with fixed orthodontic appliances [8]. During the initial phase of treatment which include alignment and leveling nickel-titanium is the best wire for releasing constant and light forces that improve the efficiency and efficacy at this stage of treatment [1,17]. Nickel-titanium wires have been developed with greater spring back and a larger recoverable energy than stainless steel or beta- titanium wires when activated by the same amount of bending or torqueing [18]. This agrees with the results of the current study.

The results of this study agree with the study of Segner et al. [19], and Nakano H et al. [16] who observed great variation in force values with different nickel-titanium wires of the same diameter indicating that the wires are intrinsically different and therefore can be differentiated according to their characteristics. Lombardo et al. [1] stated that mechanical properties of nickel-titanium alloy wires are greatly influenced by different technological parameters such as chemical composition, heat treatment and degree of working which are beyond the manufacturer classification. This agrees with the current study that shows a great variance between the deflection rate in response to unloading force effect, the A-star wire had the lowest deflection record, followed by IOS wire, whereas the DENXY wires had the greater deflection value. An important issue considering that minor differences in the production process of super elastic wires can lead to sizeable thermomechanical variations in the behavior of the arch wires [20].

Pratten et al. [21] and Fruge et al. [22] disagree with the results of the current study who stated that the types of ligatures and design of brackets had significantly influenced on the actual amount of deactivation force than wires manufacture that both affect the frictional force. Kazuo et al. [23] stated that the nonlinearity deflection of orthodontic wires was affected more by the cross-sectional shape than by mechanical properties, this also disagrees with this study.

Conclusion

In the present study the comparisons of mean load-deflection values of super elastics nickel titanium orthodontic wires from three different manufactures IOS, A star and DENXY revealed that the least mean of wire deflections recorded for the A-star wire which may exhibit superior elastic properties in comparison with the other manufacturers included in the current study, the IOS wire type load deflection results exhibit greater load deflection rate whereas the greatest mean was for the DENXY wire type.

References

- Lombardo L, Marafioti M, Stefanoni F, et al. Load deflection characteristics and force level of nickel titanium initial archwires. Angle Orthodont 2012; 82:507-21.

- Pandis N, Eliades T, Partowi S, et al. Forces exerted by conventional and self-ligating brackets during simulated first- and second-order corrections. Am J Orthod Dentofacial Orthop 2008; 133:738-742.

- Shenai A. Load deflection ratios of various initial Ni-Ti wires. Int J Physics Applications 2018; 10:1-2.

- Poon RW, Yeung KW, Liu XY, et al. Plasma immersion ion implantation of nickel titanium shape memory alloy. Biomaterials 2005; 26:2265-2272.

- Brantley WA, Eliades T. Orthodontic materials: scientific and clinical aspects. Am J Orthodont Dent Orthop 2001; 119:672-673.

- Birnie D. Excellence in orthodontics. 2005; 132-182.

- Biesiekierski A, Wang J, Gepreel M, et al. A new look at biomedical Ti-based shape memory alloys. Acta Biomaterial 2012; 8:1661-1669.

- Bartzela TN, Senn C, Wichelhaus A. Load-deflection characteristics of superelastic nickel-titanium wires. Angle Orthodont 2007; 77:991-998.

- Haixia G, Hongli S, John W, et al. The effect of orthodontic clinical use on the mechanical characteristics of nickel-titanium closed-coil springs. J Int Med Res 2019; 47:803-814.

- Agwarwal A, Agarwal DK, Bhattacharya P. Newer orthodontic wires: A revolution in orthodontics. Orthodont J 2011; 06:332.

- Schemann-Miguel F, Cotrim-Ferreira F, Streva AM, et al. Comparative analysis of load/deflection ratios of conventional and heat-activated rectangular NiTi wires. Dent Press J Orthodont 2012; 17:e1-6.

- Heinen R, Miro S. Micromechanical modeling of NiTi shape memory alloys including austenite, R-phase, and martensite. Computational Methods Applied Mathematics 2012; 229:44-55.

- Fernandes DJ, Elias CN, Vidal R, et al. Mechanical performance of Nickel-Titanium archwires. Materials Res 2015; 18:1264-1277.

- Muraviev SE, Ospanova GB, Shlyakhova MY. Estimation of force produced by nickel-titanium superelastic archwires at large deflections. Am J Orthod Dentofacial Orthop 2001; 119:604-609.

- Higa RH, Semenara NT, Henriques JFC, et al. Evaluation of force released by deflection of orthodontic wires in conventional and self-ligating brackets. Dent Press J Orthod 2016; 21:91-97.

- Nakano H, Satoh K, Norris R. Mechanical properties of several nickel - titanium alloy wires in three -point bending tests. Am J Orthod Dentofacial Orthop 1999; 115:390-395.

- Nucera R, Gatto E, Borsellino C, et al. Influence of bracket-slot design on the forces released by superelastic nickel-titanium alignment wires in different deflection configuration. Angle Orthod 2013; 1-7.

- Lin L, Currier GF, Kadioglu O, et al. Flexural properties of rectangular nickel-titanium orthodontic wires when used as ribbon arch wires. Angle Orthodont 2019; 89:54-63.

- Segner D, Ibe D. Properties of superelastic wires and their relevance to orthodontic treatment. Eur J Orthod 1995; 17:395-402.

- Gurgel JA, Kerr S, Powers JM, et al. Force deflection properties of superelastic nickel titanium arch wires. Am J Orthod Dentofacial Orthop 2001; 120:378-382.

- Pratten DH, Popli K, Germane N, et al. Frictional resistance of ceramic and stainless-steel orthodontic brackets. Am J Orthod Dentofacial Orthop 1990; 98:398-403.

- Fruge BJ. Forces from super elastic Cu-NiTi orthodontic leveling self-ligated bracket sets. Thesis, Saint Lous University 2008.

- Hayashi K, Araki Y, Mizoguchi I. Nonlinear large -deflection analysis of orthodontic wires. Angle Orthod 2008; 74:112-117.

Author Info

Afnan Jamaluddin*, Rasha Y Al-Darzi and Aseel Fadhil Yassin

Department of Pedodontics, Orthodontics and Preventive Dentistry. College of Dentistry, University of Mosul, IraqCitation: Afnan Jamaluddin, Rasha Y Al-Darzi, Aseel Fadhil Yassin, Comparison of First order Loads Deflection Forces of Super-Elastic Nickel Titanium Arch Wires (An In Vitro Study), J Res Med Dent Sci, 2021, 9 (1): 166-169.

Received: 28-Oct-2020 Accepted: 17-Dec-2020