Research - (2021) Volume 9, Issue 11

Comparative Evaluation of Effect of Resin Protective Coatings on the Surface Hardness and Shear Punch Strength of Different Glass Ionomer CementsâAn In Vitro Study

Niharika Mishra1*, Manish Agarwal2, Singh MP3, Khushboo Magwa2, Sonal Singh Thakur4 and Sonal Singh Arora4

*Correspondence: Niharika Mishra, Department of Conservative Dentistry and Endodontics, Mansarovar Dental College Hospital and Research Center, Bhopal, India, Email:

Abstract

Background: Glass Ionomer Cements (GIC) is not indicated in stress bearing posterior tooth regions due to their low fracture strength, toughness and wear. Resin coatings have been known to reduce such vulnerabilies. G-Coat Plus, a Nano-filled, self-adhesive light cured protective coating that strengthens, protects and enhances glass ionomer restorations. However, there is limited information on their influence on GIC. Hence the study was conducted to compare the effect of resin coating on surface hardness and Shear punch strength of newer modified GIC. Materials and Methods: 120 samples of Fuji IX Extra, Fuji IX Fast, Fuji II LC were prepared using specialized metal moulds. Some were coated with G-Coat plus and some left uncoated. They were then tested for surface hardness and shear punch strength. P < 0.05 was considered as significant. Results: The highest mean value on shear punch strength seen with Fuji IX Extra 46.36 ± 8.27 followed by Fuji II LC 46.26 ± 7.55 and the lowest value was seen with Fuji IX Fast 24.02 ± 3.42 with resin coating, while in surface hardness, Fuji IX extra was the highest with 75.80 ± 8.59 followed by Fuji IX Fast 64.80 ± 6.53 and Fuji II LC with resin coating 64.50 ± 5.66 (p<0.05). Conclusion: Resin coating the surfaces of GIC restoration enhances the strength and longevity of Glass ionomer restorations compared to the uncoated surfaces. Fuji IX Extra along with G-Coat plus is an ideal restorative material in posterior stress bearing areas.

Keywords

GIC, Shear strength, Surface hardness, Aesthetic, Restorative material, Nano-filler coating.HOW TO CITE THIS ARTICLENiharika Mishra, Manish Agarwal, Singh MP, Khushboo Magwa, Sonal Singh Thakur, Sonal Singh Arora,

Introduction

During the last decades, advancements in research have led to new restorative materials, most commonly resin composites and glass-ionomer cements (GICs) [1]. GIC was invented by Wilson and Kent in 1969 at the Laboratory of the Government Chemist in London, United Kingdom [2]. These materials are used extensively in restorative dentistry largely due to their adhesive, tooth-coloured, anti-cariogenic properties due to fluoride leaching ability and their usefulness in variety of clinical situations as restorative, lining, luting and sealing; no other restorative material has such wide applications [3].

The high sensitivity to water during initial setting of the cement results in lower strength of the surface subsequently low wear resistance, dimensional alteration, micro cracks, lack of adhesion and low flexural strength. This in turn limits the use of GIC in posterior stress bearing tooth regions [4]. To decrease the vulnerability of conventional GIC and its hybrid version to moisture, surface protectors are recommended, such products include varnishes, petroleum jelly (solid, liquid), nail varnishes and resin coatings [5]. G- Coat Plus (GC Corporation, Tokyo, Japan) is a nano-filled, self-adhesive light cured protective coating that strengthens, protects and enhances the longevity of GIC restorations [6-8]. There is paucity in the literature about the effect of nanofilled resin coatings on the newer generations of GIC such as Fuji IX Extra, Fuji IX Fast and Fuji II LC (GC Corporation, Tokyo, Japan). Hence, the aim of present study was to compare and evaluate the effect of nano-filled resin coating on the surface hardness and shear punch strength of newer modified GICs namely Fuji IX Extra, Fuji IX Fast and Fuji II LC.

Materials and Methods

The present study was approved by the institutional ethical board of People’s college of dental sciences and research institute (2014 CON02]. 120 samples (N=120) three GICs i.e. Fuji IX Extra (GC Corporation), Fuji IX Fast (GC Corporation), Fuji II LC (GC Corporation) (Figure 1) were prepared using customized metal moulds with dimensions (10 mm x 2mm) (Figure 2).

Figure 1:Armamentarium used in the study - (Fuji II LC, Fuji IX Fast, Fuji IX Extra, G- Coat Plus).

Figure 2:Stainless steel split moulds (Custom made).

These specimens were prepared by compressing the GIC material between two glass slides (76mm x 26mm x 1mm), separated by the split metal mould. The upper surfaces of unset specimen were covered with thin Mylar strips (Rite Dent, India). Specimens of Fuji II LC were irradiated using Blue phase CB Polywave LED polymerization equipment at 1200 mW/ cm2 for 20 seconds. The polymerization of the specimen was carried out on each side top and bottom sides against the strip and glass slides and samples were polymerized for 20 seconds after removal from the mould. Then specimens of each group were divided into subgroups of 10 into which 10 were coated with G- Coat Plus resin coating and irradiated using Blue phase CB Polywave LED polymerization equipment at 1200m W/cm2 for 20 seconds.

Inclusion criteria

Samples free of any defects and scratches when observed under magnification.

Exclusion criteria

Samples with any uneven margins, any defects and scratches.

The Surface hardness specimens were removed from the mould and any flash of Material was trimmed away with sand paper.

Then all the specimens were kept in Saline at 37o C prior to testing for 2 weeks (Figure 3).

Figure 3:GIC samples without coat and with coat in saline.

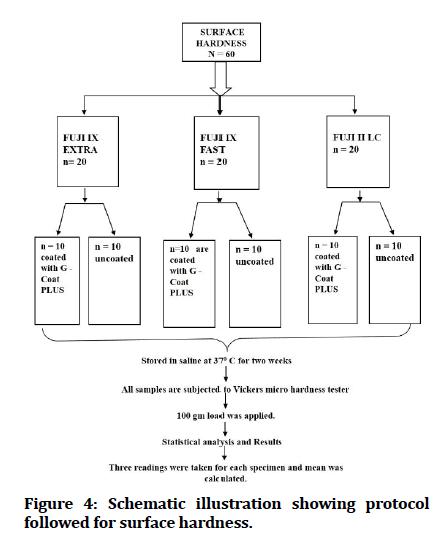

For Surface Hardness testing, prepared samples were tested and evaluated using the Vicker‘s micro hardness tester (Reichert Austria Make, Sr. No. 363798).

The Diamond Indentor is positioned on the sample surface. 100 g load applied for 20 seconds dwell time. Indentor is removed & Indentation measured.

Vicker Hardenss is noted from the Chart provided. The Shear punch strength specimens were removed from the mould and any flash of Material was trimmed away with sand paper.

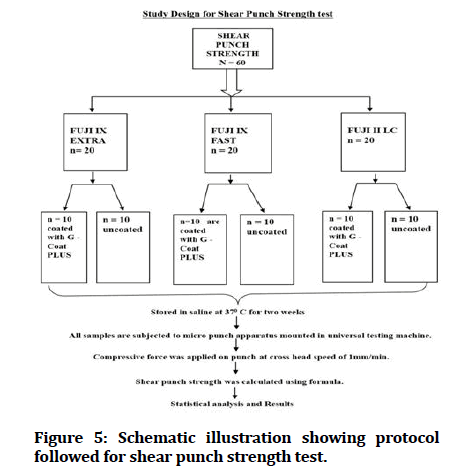

Then all the specimens were kept in distilled water at 37o C prior to testing for 2 weeks. The protocol followed for testing is illustrated in (Figures 4 and 5).

Figure 4:Schematic illustration showing protocol followed for surface hardness.

Figure 5:Schematic illustration showing protocol followed for shear punch strength test.

Specimen testing for shear punch strength

All the specimens were kept individually in the micro punch apparatus mounted on Universal testing machine (Star testing systems, India). The thickness of each specimen was measured with the digital micrometre (Mitutoyo, Japan) with an accuracy of 0.001 mm. The compressive force was applied on the punch at cross head speed of 1 mm/ min & maximum load was recorded.

Shear punch strength was calculated using formula:

Shear strength (MPa)=Force (N)/3.14 X Punch diameter (mm) X Thickness of Specimen (mm)

Data was entered in Microsoft excel. Mean and standard deviation (SD) of shear punch strength (MPa) in different glass ionomer/restorative materials with or without resin coat were calculated. Shapiro-Wilk test showed that shear punch strength (MPa) follow normal distribution. Hence parametric test, two way ANOVA (analysis of variance) followed by LSD post Hoc test was applied for comparison between different groups. P value <0.05 was considered statistically significant. All analyses were performed using version 21.0 of the Statistical Package for social sciences (IBM Corporation, Armonk, New York, U.S.A.).

Results

For Shear Punch Strength testing, the thickness of each specimen was measured with the digital micrometre (Mitutoyo, Japan) with an accuracy of 0.001 mm at cross head speed of 1 mm/ min & maximum load was recorded.

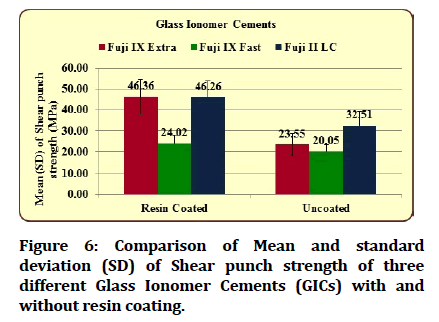

Table 1 and Figure 6 show the mean values for Shear punch strength of three different GICs with and without coating. The highest mean value was seen with Fuji IX Extra 46.36 ± 8.27 followed by Fuji II LC 46.26 ± 7.55 and the lowest value was seen with Fuji IX Fast 24.02 ± 3.42 with resin coating. Without resin coating mean and standard deviation value was highest for Fuji II LC 20.05 ± 3.40 followed by Fuji IX Extra and lowest for Fuji IX Fast. The result obtained was statistically significant (P< 0.001). The interaction between GICs and Resin coating was statistically significant on Shear punch Strength in coronal sections (F=11.929, p<0.001).

Figure 6:Comparison of Mean and standard deviation (SD) of Shear punch strength of three different Glass Ionomer Cements (GICs) with and without resin coating.

| GICs | Mean ± SD of shear punch strength (MPa) of resin coated and uncoated materials | p-Value | |

|---|---|---|---|

| Resin Coated | Uncoated | ||

| Fuji IX Extra | 46.36 ± 8.27 | 23.55 ± 5.21 | 0 |

| Fuji IX Fast | 24.02 ± 3.42 | 20.05 ± 3.40 | 0.001 |

| Fuji II LC | 46.26 ± 7.55 | 32.51 ± 6.91 | 0.001 |

Table 1: Mean and standard deviation (SD) of Shear punch Strength (MPa) of three different GICs (GICs) with and without resin coating.

| GICs | Mean ± SD of Surface hardness (VHN) of resin coated and uncoated materials | p-Value | |

|---|---|---|---|

| Resin Coated | Uncoated | ||

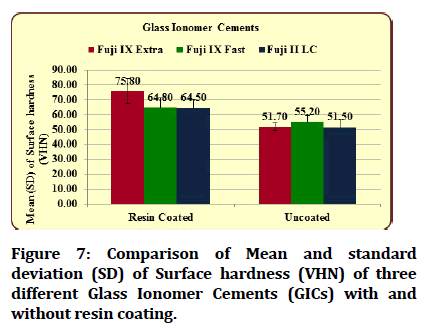

| Fuji IX Extra | 75.80 ± 8.59 | 51.70 ± 2.63 | 0.009 |

| Fuji IX Fast | 64.80 ± 6.53 | 55.20 ± 4.02 | 0 |

| Fuji II LC | 64.50 ± 5.66 | 51.50 ± 5.26 | 0.001 |

Table 2: Mean and standard deviation (SD) of Surface hardness (VHN) of three different GICs (GICs) with and without resin coating.

Table 2 and Figure 7 shows the mean values of Surface Hardness of three different GICs with and without coating. Within the cements, the highest mean value was seen with Fuji IX Extra 75.80 ± 8.59 followed by Fuji IX Fast 64.80 ± 6.53 and lowest for Fuji II LC with resin coating 64.50 ± 5.66. Without resin coating mean and standard value was highest for Fuji IX Extra followed by Fuji IX Fast and lowest for Fuji II LC. The mean Surface hardness differ significantly between different GICs (P< 0.001). When LSD post hoc test was applied it showed that mean Surface hardness in Fuji IX Extra was significantly higher than Fuji IX Fast and Fuji II LC. The interaction between GICs and Resin coating was statistically significant on Surface hardness (F=8.664, p<0.01). There was no significant difference between Fuji IX Extra, Fuji IX Fast and Fuji II LC for Surface hardness among the uncoated materials.

Figure 7:Comparison of Mean and standard deviation (SD) of Surface hardness (VHN) of three different Glass Ionomer Cements (GICs) with and without resin coating.

Discussion

In recent years, there have been considerable modifications made in the formulations to improve thier handling properties. In spite of these advantages, conventional glass ionomers suffer from short working times and long setting times, brittleness, low fracture toughness, poor resistance to wear, susceptible to moisture contamination or dehydration during the early stages of the setting reaction [9]. They are not the preferred restorative of choice in the posterior regions where the masticatory load is high. This makes them susceptible to fracture due to their low strength. Over the past years, several modifications have been done to enhance the physical and mechanical properties of GIC.

Surface protectors are usually recommended during their initial set in order to protect them from moisture. Today several commercial products are available such as coca butter, petroleum jelly), waterproof varnishes (based on nitrocellulose) and resins (methyl methacrylate, amide and preferably filled, light-cured, bonding resins) varnishes [10,11]. Studies have shown sealing of the cement prior to initial set produces optimal compressive strength [12,13]. G-Coat Plus, a nano-filled self-adhesive light cured protective coating that strengthens, protects and enhances the longevity of glass ionomer restorations, composite resin and temporary restorations.

Kato et al studied the influence of the various coating materials for the conventional restorative GIC, Fuji IXGP EXTRA (F9E) on its properties and concluded that F9E coated with G-COAT PLUS showed the highest flexural strength. Tensile bond strength of G-COAT PLUS is significantly higher than other products [14]. The strength of auto-cured cements has been shown to increase over a 1-year period. A recent study found that the strength of a high strength auto-cured glass ionomer reached a maximum within 1 to 2 weeks for resin-coated and uncoated specimens, respectively [14].

The effect of coating on two commercial glass-ionomer cements by either petroleum jelly or wax was studied by Samantha E. Booth et al [15]. Coating with wax had increased the surface hardness significantly compared with the uncoated control, whereas coating the specimens in petroleum jelly led to only a slight increase in surface hardness. This study thus confirmed the idea that immature glass-ionomers be protected from early exposure to moisture, and that the protection offered by petroleum jelly is only modest. There are studies which contradict early contact of GIC with water, decrease the strength of GICs. The findings in our study was in agreement with Bagheri et al who determined the effect of G- Coat Plus on the mechanical properties of GICs and they concluded that the mechanical properties of the restorative materials were affected by applying G-Coat Plus and distilled water immersion over time [16].

In our study, we evaluated and compared the effect of resin coating on two important properties- Surface hardness and Shear punch strength of newer modified GICs coated with a resin protective agent. The thickness of each specimen was measured with a digital micrometre with an accuracy of 0.01-mm prior to placement in the shear punch apparatus. The mean Shear punch Strength differed significantly from the resin coated and uncoated materials. In Resin coated materials, mean Shear punch Strength in Fuji IX Extra and Fuji II LC was significantly higher than Fuji IX Fast. There was no significant difference between Fuji IX Extra and Fuji II LC. In Uncoated materials, mean Shear punch Strength in Fuji II LC was significantly higher than Fuji IX Extra and Fuji IX Fast with no significant difference between Fuji IX Extra and Fuji IX Fast. The higher strength of the resinmodified (Fuji II LC), when compared to its conventional auto-cured counterpart (Fuji II), was in agreement with previous studies [17].

Bala et al in evaluated the amount of micro leakage at the interface of different restorative materials and tooth surface in class II restoration. They concluded that reduction in micro leakage was seen with protective coating compared to samples without coating [18]. Within the types of restorations, Resin modified GIC showed least micro leakage followed by Polyacid modified resin composites and Resin composite.

Second important property which influences the longevity of restoration is hardness of restorative material. It is defined as the resistance to surface indentation. According to Zhang YR et al the Vickers Hardness test is a method used for brittle materials, in which a pyramidal indentation is made using a specified load and application time, the resultant hardness number being independent of the applied load [19]. For present study the dimensions of the specimens were 10mm x 2mm which is analogus to the method described by Bala et al [18]. The specimens coated with G–Coat Plus were harder than those left uncoated. The mean Surface hardness in Resin coated materials was significantly higher than uncoated materials.

Xie et al [19]determined the flexural strength (FS), compressive strength (CS), diametral tensile strength (DTS), Knoop hardness (KHN) and wear resistance of ten commercial glass-ionomer cements (GICs). They found that larger glass particle sizes and a more integrated microstructure contributed to a higher wear resistance. The mechanical property of GICs were closely related to their microstructures. Factors such as the integrity of the interface between the glass particles and the polymer matrix, the particle size, and the number and size of voids have important roles in determining the mechanical properties.

It is important to state that there are many factors in the oral cavity which influence the functioning and longevity of restoration i.e. micro leakage, cyclic changes of occlusal load. This present study has some limitations as it could not completely replicate the complex oral environment. The role of artificial saliva, thermo cycler was not taken into consideration. Such a lack of these conditions in vitro studies may limit the possibility of extrapolating these findings to in vivo situation. Further in vitro and in vivo studies are recommended to correlate with the results of the present study. So, it is suggested that, in future clinical studies it is also necessary to compare the advantages of different protective agents over conventional GIC and its hybrid combinations.

Conclusion

Fuji IX Extra accompanied with Nano filler resin coating exhibits superior shear punch strength and hardness and represent an ideal posterior restorative material. They can be incorporated into daily clinical practice to enhance the strength and longevity of GICs.

Acknowledgement

The authors would like to thank and acknowledge the assistance of Centre for Scientific Research and Development, People's College of Dental Sciences and Research Centre, Bhopal for equipping us with the stereomicroscope.

References

- Lohbauer U. Dental glass ionomer cements as permanent filling materials?–properties, limitations and future trends. Materials 2010; 3:76-96.

- https://patents.google.com/patent/GB1316129A/en

- Sidhu SK. Glassâ?ionomer cement restorative materials: a sticky subject?. Aust Dent J 201; 56:23-30.

- van Duinen RN, Kleverlaan CJ, de Gee AJ, et al. Early and long-term wear of ‘Fast-set’conventional glass–ionomer cements. Dent Mater 2005; 21:716-20.

- Saleh LA, Khalil MF. The effect of different protective coatings on the surface hardness of glass ionomer cements. Saudi Dent J 1994; 6.

- Wilder AD, Swift EJ, May KN, et al. Effect of finishing technique on the microleakage and surface texture of resin-modified glass ionomer restorative materials. J Dent 2000; 28:367-73.

- Nagaraja Upadhya P, Kishore G. Glass ionomer cement: The different generations. Trends Biomater Artif Organs 2005; 18:158-65.

- Williams JA, Billington RW, Pearson GJ. Effect of moisture protective coatings on the strength of a modern metalâ?reinforced glass–ionomer cement. J Oral Rehabil 1998; 25:535-40.

- Hattab FN, Amin WM. Fluoride release from glass ionomer restorative materials and the effects of surface coating. Biomaterials 2001; 22:1449-58.

- Mount GJ. Glass-ion omer restorative cements: Clinical-implications of the setting reaction. Oper Dent 1982; 7:134-41.

- Causton BE. The physico-mechanical consequences of exposing glass ionomer cements to water during setting. Biomaterials 1981; 2:112-115.

- Kato K, Yarimizu H, Nakaseko H, et al. Influence of coating materials on conventional glass-ionomer cement. J Dent Res 2008; 87:487.

- Booth SE, Deacon AD, Coleman NJ. Properties of glass-ionomer cements sealed with petroleum jelly or wax. Int J Mater Metall Eng 2012; 6:1133-6.

- Bagheri R, Azar MR, Tyas MJ, et al. The effect of aging on the fracture toughness of esthetic restorative materials. Am J Dent 2010; 23:142.

- Sidhu SK, Watson TF. Resin-modified glass ionomer materials. A status report for the American journal of dentistry. Am J Dent 1995; 8:59-67.

- Mishra N, Agarwal M, Singh MP, et al. Comparative Evaluation of effect of resin protective coatings on the surface hardness and shear punch strength of different GlCs-An InVitro Study. Endod Today 2021; 19:160-5.

- Zhang YR, Du W, Zhou XD, et al. Review of research on the mechanical properties of the human tooth. Int J Oral Sci 2014; 6:61-69.

- Bala O, Arisu DH, Yikilgan I, et al. Evaluation of surface roughness and hardness of different glass ionomer cements. Eur J Dent 2012; 6:79-86.

- Xie D, Brantley WA, Culbertson BM, et al. Mechanical properties and microstructures of glass-ionomer cements. Dent Mater 2000; 16:129-38.

Author Info

Niharika Mishra1*, Manish Agarwal2, Singh MP3, Khushboo Magwa2, Sonal Singh Thakur4 and Sonal Singh Arora4

1Department of Conservative Dentistry and Endodontics, Mansarovar Dental College Hospital and Research Center, Bhopal, India2Department of Conservative Dentistry and Endodontics, People's College of Dental Sciences and Research Centre, Bhopal, India

3Department of Dentistry, Chirayu Medical College and Hospital, Bhopal, India

4Department of Conservative Dentistry and Endodontics, Sri Aurobindo College of Dentistry, Indore, India

Received: 20-Sep-2021 Accepted: 10-Nov-2021