Research Article - (2022) Volume 10, Issue 9

Biomechanical and Histomorphometric Analysis of Maxphase (Ti2AlC) Alloy as an Implant

Luma M Ibrahim1*, Raghdaa K Jassim1 and Ahmed Al Gabban2

*Correspondence: Luma M Ibrahim, Department of Prosthodontics, College of Dentistry, University of Baghdad, Iraq, Email:

Abstract

Background: The type of implant material for bone ingrowth with appropriate biomechanical properties has long been sought as the ideal bone implant interface. This study aimed to assess the influence of max phase alloy (Ti2AlC) implant on the new bone in growth and biomechanical (push out bond strength test). And this was in comparison with Ti6Al7Nb and cpTi.

Materials and methods: A cylindrical implant was prepared from MaxphaseTi2AlC, Ti6Al7Nb and cpTi with these dimensions (8 × 3) mm height and diameter respectively. In this study, white, male New Zealand rabbits, weighing (2-2.5 kg), aged (10-12 months) were used for implantation of implant cylinder in femur. Then biomechanical (push out bond strength test) and Histomorphometric analysis was performed after 2 and 6weeks of post-surgical implantation. Statistical analysis was performed for data using SPSS version 24.

Results: In this research, Ti2AlC implants achieved the highest push out bond strength. and the recorded mean value for Ti2AlC (10.425+1.155) Mpa as compared with the Ti6Al7NB (7.7630+0.800) Mpa and cpTi implants (3.1440+0.779) Mpa after 2 week implantation in rabbit. Similarly, differences was observed after 6 week implantation. For the histomorphometric analysis, TI2AlC implant recorded a statistically highly significant diferancesis in the mean values of bone and bone implant contact as compared with TI6Al7NB and cpTi.

Conclusion: With in limitation of the present study it can be concluded that, the bone implant interface strength of max phase alloyTi2AlC implant was higher than that of Ti6Al7Nb and cpTi after 2 and 6 weeks implantation in femur of rabbit. And this was coincide with the higher amount of bone and bone implant contact associated with the same material.

Keywords: Bone healing, CPT, Ti6Al7Nb, Ti2AlC, Histomorphometric, Implant

Introduction

Osseo integration is defined as ‘a direct structural and functional connection between ordered, living bone and the surface of a load bearing implant’ [1]. The Osseo integration of dental implants is related to type of material, which can be determining factors for rapid and intimate bone implant contact. Commercial pure titanium is an excellent implant material because of its high corrosion resistance and outstanding biocompatibility. It is known for not causing allergic reactions and it is preferred when infection is a risk. Its low elastic modulus and flexibility are advantages in many applications. The mechanical properties can be modified in a certain range by choosing a suitable titanium grade and by work strengthening. Where a higher strength is required than offered by the commercial pure Titanium [2,3].

However, in the last few years, implants made of titanium alloys has been studied in detail as alternative biomaterials for replacement of missing teeth [4,5]. While titanium alloys such as Titanium 6-Aluminum 7-Nubium (Ti6Al7Nb) possess better mechanical properties than commercially pure grade 4 titanium, zirconia or compound ceramics have other advantages over titanium or titanium alloys. Surface modifications of these more recently introduced biomaterials were found also to influence the Osseo integration process [6-8].

For titanium and its alloys, physical and chemical properties appear suitable for dental implants and prostheses.For more than five decades, cpTi used in dentistry, but there still seems to be potential to improve this material and its processing techniques to avoid possible biomechanical or biological complications [9].

Max phase alloy (Ti2AlC) is studied as a potential alternative for dental implant. Ti2AlC belongs to a class of ternary carbides and nitrides that belongs to the MAX phase whose unique combination of metallic and ceramic-like properties has sparked great interest [10]. They possess unusual and even unique physical, chemical, mechanical and electrical properties with high corrosive resistance which could make them an excellent practical biocompatible strong dental implant. The significant demand for the applications of Ti2AlC applications is attributed to the low cost of raw materials, low density, and crack-healing capabilities [11].

Barsoum et al. synthesized a relatively pure sample of these materials incorporating metallic and ceramic properties at the same time,these materials which are produced so far in various forms: powder, bulk material, coating, a thin layer (film), and metallic (foam) demonstrate a combination of ceramic properties and metallic properties at the same time[12].

Ibrahim et al. in manufacture and characterize Ti2AlC alloy in cylinder form with adequate properties like compression strength test and surface feature characterization [13].

The design of this study to evaluate the biomechanical push out bond strength and histomorphometric parameters of cylinder implant made from Ti2AlC and compares with cpTi and TiAl7Nb after 2 and 6 weeks implantation in the tibia of rabbits.

Materials and Methods

The design of this study was to evaluate the strength of bone/implant contact using of biomechanical push out bond strength test and histomorphometric analysis after 2 and 6 weeks post-surgical implantation of cylinder in rabbit. The procedure started with the following: Cylindrical implants preparation: cylinders were prepared from the following materials.

- Max phase alloy Ti2AlC which was prepared according to [13]

- Ti6AL7Nb

- CpTi

The dimensions of cylinder were (8 × 3) mm height and diameter respectively. Then each cylinder was put inside an airtight plastic package and sterilized at 1340°C for 4 min at class B cycle [14].

In vivo experiment

The animal study was approved by the Animal Ethics Committee in the college of dentistry, Baghdad University; all experiments were performed following the institutional guidelines and regulations of the Iraqi Veterinary Medical Syndicate in Iraq.

Adult, white males New Zealand rabbits about 10-12 months age and (2-2.5) Kg were used as experimental animals.

Experimental rabbits were divided into two main groups according to the healing interval into 2 and 6 weeks. Further sub-division related to push out bond strength test and histomorphometric analysis, three implants were implanted in the proximal third of the lateral aspect of the femoral bone. The Ti2AlC and Ti6Al7Nb screw were implanted in the right femur while the cpTi cylinder was implanted in the left femur. In both femurs, the implantation process is done from the mesial bone side to the distal one.

Surgical procedure for placement implant as follow: Intramuscular injection of Ketamine hydrochloride 50 mg (1 ml/kg B.W) and xylocaine 2% (1 ml/kg B.W) was used to anesthetize the rabbits [15].

When an adequate state of anesthesia was achieved, an eye drops were placed on each rabbit’s eye to prevent its dryness. Buprenorphine (0.05 mg/kg) was also administered intramuscularly to control postoperative pain. Intravenous fluids (5-10 ml lactated ringers’ solution) were administered via subcutaneous injection. The animal’s body temperature and oxygen saturation were monitored continuously during surgery [15-17].

The site of operation (lateral part of the both femoral bone) prepared by hair shaving (by using shaving spray and machine) and the skin cleaning by tap water and surgical soap then disinfect the area with 70% alcohol, surgical towels were placed around the shaved cleaned femurs operation site, then cleaned by iodine-ethanol mixture followed by five minutes scrubbed the skin with alcohol damped piece of cotton [15].

The lateral side of the femur exposure by an incision about 3 cm in length to the skin, fascia and periosteum of the lateral side of the rabbit’s femur with a sharp blade Figure 1, then the fascia flap and skin was reflected as shown in Figure 1 [14-16].

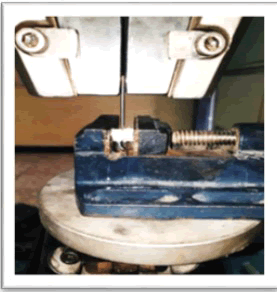

Figure 1: Instron universal testing Machine with bone/implant block.

The femoral bone carefully exposed, and then bone penetration was performed with pointed starter guide drill, and then with surgical drill to make two holes with 1 cm distance between them this done in one femur, and in the other one hole was done.

The drilling was made by using the implant surgical engine the drilling was done with intermittent pressure and continuous cooling with normal saline at a rotary speed of 1200 rpm. After that the implant bed was cleaned from the drilling debris with normal saline, the implant specimens were removed from the plastic sheet and placed in holes with slight tapping pressure with surgical hammer until 3 mm was the muscles and the skin were sutured with absorbable (3/0) catgut suture and (3/0) non-absorbable silk suture respectively figure. The operation site was cleaned with iodine and sprayed with local antibiotic (oxytetracycline spray) then covered with sterilized gauze that replaced daily with injection of systemic antibiotic (oxytetracycline 20%, 0.5 ml/kg B.W) once daily for (5) days [15].

After surgery the health of rabbits beside the site of operation checked daily for any infections and complication. The animals were under superintendence for 2 weeks and 6 weeks.

Biomechanical (Push out bond strength Test): according to the design of study the rabbits were sacrificed after 2 and 6 weeks’ time intervals. Right and left femurs with implant specimens were dissected and all flesh was removed. On the same day as euthanasia, push out bond failure was done by using an Instron universal testing machine [18].

The clearance hole was made below the implant specimen at least 3.5 mm in diameter to record the pure force required for the implant/bone bond breakage, the femur was fixed in a clamp for support the bone, and the clamp was fixed in the universal testing machine as shown in (Figure 1). The specimen was loaded at a rate of 1 mm/min, load was applied to the implant specimen through a specially designed plunger, with cylindrical working head 3 mm in diameter, connected to the crosshead of the universal testing machine, The maximum load of failure was recorded in Newton (N), the apparent shear stress was obtained from dividing the maximum load on the contact area which was the periphery of cylindrical implant specimen [19].

Histomorphometric analysis

It include calculating the areas of the thickness of the bone trabeculae tissue around the implant bar and bone implant contact BIC for all the groups. Rabbits were scarified for each healing period (2 and 6) weeks for histomorphometric examination by overdose anesthetic solution [16].

Bone implant block was prepared by cutting the femur bone about 5 mm away from the implant and then they stored immediately in 10% newly freshly prepared buffered formalin for fixation [15,16].

Preparation of the specimens. This step include the following

- Fixation: The specimens were immediately fixed in 10% freshly prepared neutral buffered formalin for 3 days.

- Decalcification: The specimens were left in formic acid-sodium citrate solution which was prepared freshly from 2 solutions:

Solution A: 125 cc formic acid 90%, 125 cc distilled water.

Solution B: 50 mg sodium citrate, 250 cc distilled water.

After that the two solutions were mixed and the specimens put in it, to have decalcification of the bone the solutions were changed every 3 days.

Decalcification of the bone was checked using a narrow needle. The bone was considered to be decalcified when the needle could penetrate to the deepest part of the bone in the sockets blocks. Washing the specimens with tap water.

Dehydration: The specimens were dehydrated by passing them through a series of increasing of alcohol concentration (40%, 60%, 80%, 95%, and absolute alcohol).

Then the specimens were passed through two jars of xylene, each jar for half an hour.

Embedding: The specimens were placed in a dish of melted embedding paraffin and the dish was put into a constant temperature oven regulated about 53-60°C.

During the course of several hours, the specimen was changed to two successive dishes of paraffin so that all of the xylene in the tissue was replaced by paraffin (each dish for one hour).The specimen was placed in the centre of block paraffin Sectioning. Five µm thick semi serial cross sections of the implant site were mounted on clean glass slides for routine haematoxylin and eosin staining (H and E).

Hematoxylin and eosin stain

The obtained sections were de-waxed with xylene and dehydrate in descending alcohol concentration.

- Stained with Mayer's hemotoxylin stain for 7-10 min.

- Washed in tap water 1-5 min to remove the excess stain

- Stained with eosin for 1-2 min.

- Dehydrated in absolute alcohol for 2-3 min and clear with xylene.

- Cover slips were fixed on stained tissues using D.P.X.

Examined under the light microscope for histomorphometric. Histomorphometric findings were estimated by means of three characteristics in six quadrangular sections measuring 200 x 200 micrometres around the implant site.

BTT: the thickness of the bone trabeculae tissue around the implant bar; BTT was measured by means of linear measurements perpendicular to bone determined on every aspect of the implant bed sites [20].

BIC: Bone to implant contact (%) was assessed by manually measuring the relative length of bone tissue in direct contact with the implant. The measurements from both sides of the implant in three different sections were averaged and used for statistical analysis [21].

Statistical Analysis

The appropriate statistical method was followed to analyse the results by using Statistical Package for Social Sciences (SPSS) version 24.

Results

Biomechanical push out bond strength test

The results of push out bond strength test in Table 1 recorded that max phase alloy had the highest mean values at both 2 weeks and 6 weeks than both Ti6Al7Nb and cpTi. The difference was statistically significant with p-value <0.001 for both weeks.

| Time | Material | Mean | ANOVA test | |

|---|---|---|---|---|

| F | Sig. | |||

| Two Weeks | Max | 10.425 | 157.612 | 0 |

| TiAl7nb | 7.763 | |||

| CPTI | 3.144 | |||

| Six Weeks | Max | 18.172 | 127.641 | 0 |

| TiAl7nb | 9.42 | |||

| CPTI | 11.784 | |||

Table 1: Push out test for cpTi, Ti6Al7Nb and Ti2AlC at both 2 weeks and 6 weeks.

In Table 2 pairwise analysis using Bonferroni showed that there was a high statistically significant difference for max phase alloy with Ti6Al7Nb and cpTi, respectively also for both weeks. Likewise, Ti6Al7Nb had higher mean value than cpTi with P-value of 0.001 at both 2 weeks and 6 weeks.

| Time | (I) Material | (J) Material | Mean Difference (I-J) | Sig. |

|---|---|---|---|---|

| Two Weeks | Max | TiAl7nb | 2.6620* | 2.15E-06 |

| CPTI | 7.2810* | 8.22E-16 | ||

| TiAl7nb | CPTI | 4.6190* | 4.08E-11 | |

| Six Weeks | Max | TiAl7nb | 8.7520* | 1.91E-14 |

| CPTI | 6.3880* | 3.08E-11 | ||

| TiAl7nb | CPTI | -2.3640* | 0.001 |

Table 2: Bonferroni pairwise analysis between each two material at 2 and 6 weeks’ time interval.

Similarly, there was a higher mean values for the pushout test at 6 weeks than 2 weeks for cpTi, Ti6Al7Nb and Ti2AlC as shown in Table 3. Also for the differences between 2 and 6 weeks. There was a high statistically significant difference for all of them with p-value<0.001.

| Material | Time | Mean | Std. | F | Sig. |

|---|---|---|---|---|---|

| Max | 2 weeks | 10.425 | 1.1551 | 283.243 | 1.85E-12 |

| 6 weeks | 18.172 | 0.8858 | |||

| TiAl7nb | 2 weeks | 7.763 | 0.80089 | 25.43 | 8.46E-05 |

| 6 weeks | 9.42 | 0.66202 | |||

| CPTI | 2 weeks | 3.144 | 0.77956 | 177.622 | 9.16E-11 |

| 6 weeks | 11.784 | 1.89605 |

Table 3: Push out bond strength test at both 2 weeks vs. 6 weeks for cpTi, Ti6Al7Nb and Ti2AlC.

Histomorphometric analysis

Table 4 showed higher Mean values of TB (New bone) of Ti2AlC in all experimental groups after 2 and 6 weeks implantation in rabbit. A statistical analysis for the comparison among mean values of all experimental group, there was a high statistically significance difference among them with p-value<0.001. Pairwise analysis showed a high statistically significant association between Ti2AlC with both cpTi and Ti6Al7Nb with p-value <0.001. There was also a high statistically significant difference between cpTi and Ti6Al7Nb with p-value<0.001.

| Time | CPTi | Ti 6Al7Nb | Ti2AlC | |||||

|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | F-statistic | P-value | |

| 2 weeks | 16.06 | 1.052 | 17.86 | 0.78294 | 23.6 | 0.96177 | 87.906 | 6.80E-08 |

| 6 weeks | 27.5 | 1 | 36.4 | 0.89443 | 41.6 | 2.3021 | 107.415 | 2.19E-08 |

| Experimental group | Bonferroni P-value BTT after 2 and 6 weeks | |||||||

| 2 weeks | 6 weeks | |||||||

| cpTi and Ti6Al7Nb | 0.031 | 2.79E-06 | ||||||

| cpTi and Ti2AlC | 7.73E-08 | 1.73E-08 | ||||||

| Ti6Al7Nb and Ti2AlC | 1.55E-06 | 0.001 | ||||||

Table 4: Bone Tissue (TB) in all experimental groups after 2 and 6 weeks implantation in rabbit.

Table 5 showed the statistical analysis of data which is represented by the mean values of (BIC) bone implant contact, bone tissue surrounding implants after two and six weeks implantation. ANOVA test showed a high statistically significance among all experimental group after 2 and 6 weeks' implantation. Further statistical analysis by using Bonferroni, in the same table P value appear a statistically highly significant differences between all pairs of the materials.

| Time | cpTi | Ti6Al7Nb | Ti2AlC | ANOVA | ||||

|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | F-statistic | P-value | |

| 2 weeks | 3.4 | 1.14 | 4.4 | 1.1401 | 6 | 2 | 3.909 | 0.049 |

| 6 weeks | 21.44 | 1.006 | 33.56 | 0.72319 | 38.72 | 0.89833 | 503.754 | 2.66E-12 |

| Experimental group | Bonferroni P-value BIC after 2 and 6 weeks | |||||||

| 2 weeks | 6 weeks | |||||||

| cpTi and Ti6Al7Nb | 0.922 | 1.63E-10 | ||||||

| cpTi and Ti2AlC | 0.051 | 2.47E-12 | ||||||

| Ti6Al7Nb and Ti2AlC | 0.341 | 2.53E-06 | ||||||

Table 5: Bone/implant contact BIC for all experimental groups after 2 and 6 weeks implantation in rabbit.

Discussion

Despite the wide clinical utilization of Titanium implants, there are still potential risks because of the inherent bio inert and easily oxidizable characteristics. For example, the oxide layer of the surface of Titanium often leads to thrombosis between the surface and surrounding tissue, which creates an oral cavity that, promotes microbial reproduction [15]. Moreover, during the operation, inflammation around the surgical sites may occur due to external heat or pressure. This hinders the normal growth of new bone around the surgical sites and results in weak bonding between the bone and implant [16]. MAX phases are a somewhat uncertain kind of material with both metallic and ceramic properties; their classification is still unclear. These carbides possess unusual and even unique physical, chemical, mechanical and electrical properties. They are electrically and thermally conductive, machinable, and not susceptible to thermal shock, plastic at high temperatures and exceptionally damage tolerant [18-20].

Push out bond strength test had been used to assess the bond strength between implant and bone. Also it is based on shear stress at the interface between implant and bone.

Assessment of Bone implant interfacestrength using the push out test showed a high statistically significant difference between the material used with higher mean values for the strength of the bone-implant interfaceof the Max phase alloy than both cpTi and Ti6Al7Nb at both, 2 weeks and 6 weeks.

The presence of carbon in max phase alloy which appears to stimulate strong cell recruitment during the extensive bone formation which helps in faster healing time, carbon may also cause condensation reactions which provide strong covalent bonds through cell membrane lipid fatty acids/phosphate/amino-acid end groups, bone phosphate and some organic portions of the bone matrix [21,22].

Osseointegration assessment using the histomorphometric test revealed a high statistically significant difference between the material used with higher mean values for the strength of Osseointegration of the Max phase alloy than both CpTi and Ti6Al7Nb at both, 2 weeks and 6 weeks. This could be due to many factors:

Ti2AlC are exceptionally oxidation resistant which could be because they form a stable and adherent protective Alâ??Oâ?? scale which acts as protective alumina scale [24]. To see how bonding could determine the protective scale formed.

Conclusion

The conclusion of Zhou and Sun was that as the bonding created between Ti-C is strongly covalent and the one for Ti-Al is weak. The strength of the covalent bond would decrease the activity of Ti, therefore increasing the activity of Al, which is high enough then to be preferentially oxidized. These two factors mentioned; the low Al content to form a protective scale and the bonding, make the formation of a continuous Al2O3 layer on Ti2AlC favourable. Studies carried out by Meier et al. [25]. Done in Ti-Al alloy showed that they do not create a protective alumina scale but rather a scale composed of TiO2 and Al2O3. Biocompatibility could be mainly due to the excellent corrosion behaviour of the alloy in the physiological environment by a tenacious layer of protective alumina scale or the layer of scale TiO2 and Al2O3 that appear on the implant’s surface immediately after exposure to oxygen [18].

In comparison CpTi has high affinity for oxygen which allows the spontaneous formation, on the Ti surface, of a layer of Ti oxides, mainly TiO2. Those oxides represent a non-metallic layer on the Ti surface that, in the harsh conditions of biological fluids, have a tendency to grow up, constituting a brittle interface between the implant and the bone [25,26].

Ti surface is spontaneously passivated by a layer of oxides, mainly TiO2, which confer to the surface its high biocompatibility as suggested by many researchers [27,28]. TiO2 layer is a non-metallic film interposed between the implant and the bone. It is also very brittle, may be easily fractured, exposing the bulk Ti of the implant to the attack of the harsh conditions of biological environment, with a consequent production of Ti particles. These last might be toxic and induce an inflammatory reaction [29].

References

- Listgarten M, NP L, Schroeder H, et al. Periodontal tissues and their counterparts around endosseous implants. Clin Oral Implants Res 1991; 2:1-19.

- Wang R, Fenton A. Titanium for prosthodontics applications: A review of the literature. Quintessence Int 1996; 27:401–408.

- Zechner W, Ulm C, Tangl S, et al. Histologic and histomorphometric analysis of three types of dental implants following 18 months of occlusal loading: a preliminary study in baboons. Clin Oral Impl Res 2005; 16:408-416.

- Altuna P, Lucas-Taule E, Gargallo-Albiol J, et al. Clinical evidence on titanium-zirconium dental implants: a systematic review and meta-analysis. Int J Oral Maxillofac Surg 2018; 45:842-850.

- Ozcan M, Hammerle C. Titanium as a Reconstruction and Implant Material in Dentistry: Advantages and Pitfalls. Material 2012; 5:1528-1545.

- Oliviera V, Chaves R, Bertazzoli R, et al. Preparation and characterization of Ti-Al-Nb alloys for orthopedic impants. Braz J Chem Eng 1998; 15.

- Aridome K, Yamazaki M, Baba K, et al. Bending properties of strengthened Ti-6Al-7Nb alloy major connectors compared to Co-Cr alloy major connectors. J Prosthet Dent 2005; 93:267-273.

- Depprich R, Naujoks C, Ommerborn M, et al. Current findings regarding zirconia implants. Clin Implant Dent Relat Res 2014; 16:124-137.

- Lautenschlager E, Monaghan P. Titanium and titanium alloys as dental materials. Int Dent J 1993; 43:245-253.

- Barsoum NTM. Synthesis and Characterization of Ti3AlC2. J Am Ceram Soc 2000; 83:825-832.

- Zhang Hu C, H Huang Li F, et al Y. New phasesâ?? discovery in MAX family. IJRMHM 2013; 36:300-312.

- Barsoum M. The M N+1 AX N phases: a new class of solids: thermodynamically stable nanolaminates. Prog Solid State Ch 2000; 28:201-281.

- Ibrahim LM, Jassim RK, Gabban AA. Manufacturing and characterization of TIAlC maxphas alloy in comparison with cpti andT6Al7Nb as ann dental implant material 2021.

- GA Abbood, RK Jasim. Evaluation of biocompatibility of Commercial Pure Titanium/Bioactive Glass Ceramic Functionally Graded Material as Dental Implant Material In-Vivo study. Mustansiria Dent J 2019.

- Azzawi ZGM, Hamad TI, Kadhim SA, et al. "Osseointegration evaluation of laser-deposited titanium dioxide nanoparticles on commercially pure titanium dental implants." J Mater Sci Mater Med 2018; 29:96-106.

- Mohammed AA. "Evaluation of Niobium as an alternative to (coated and uncoated) commercial pure titanium dental implant: mechanical and histomorphometric study." A PhD thesis, College of Dentistry, University of Baghdad. 2018.

- Kadhim DR. "Studying the use of egg shell derived calcium carbonate as bone graft around nano calcium sulfate coated dental Implant." Master thesis, College of Dentistry, University of Baghdad. 2019.

- Wook-Jin Seong, Shahrzad Grami, Soo Cheol Jeong, et al. Comparison of push-in versus pull-out tests on bone implant interfaces of rabbit tibia dental implant healing model. Clin Implant dent relat res 2011; 12: 259-265.

- Chua AWC, Khoo YC, Tan BK, et al. Skin tissue engineering advances in severe burns: review and therapeutic applications. Burns Trauma 2006; 4.

- Togni F, Baras F, Ribas M, et al. "Histomorphometric analysis of bone tissue repair in rabbits after insertion of titanium screws under different torque." Acta Cirurgica Brasileira 2011; 26:261–266.

- Chawla K. Chapter 2 Reinforcements, 8 Carbon Fiber Composites, 10.2 Micromechanics-Mechanical Properties. In Composite Materials. 2nd ed. New York: Springer; 1998; 252–262.

- Sun ZM, Zhou YC. Electronic structure and bonding properties of layered machinable Ti2AlC and Ti2AlN ceramics. Physical Review B. 2000; 61:12570.

- Callister W. Chapters 17 Composites, 19 Electrical Properties and Appendix C Properties of Selected Materials. In Materials Science and Engineering. 4th ed. New York: John Wiley and Sons. 1997; 593–624.

- X Liu, PK Chu, C Ding, et al. Surface modification of titanium, titanium alloys and related materials for biomedical applications. Mater Sci Eng R Rep 2004; 47:49–121.

- Meier GH, Appalonia D, Perkins RA, et al. Oxidation of Ti-base alloys, in oxidation of High Temperature intermetallics. Oxidation of high temperature intermetallics 1989;185-193.

- HJ Rack, JI Qazi. Titanium alloys for biomedical applications. Mater Sci Eng C 2006; 26:1269–1277.

- P Santiago-Medina, PA Sundaram, N Diffoot-Carlo. Titanium oxide: a bioactive factor in osteoblast differentiation. Int J Dent 2015; 357653.

- W Wu, X Sun, Y Yu, et al. TiO2 nanoparticles promote beta-amyloid fibrillation in vitro. Biochem Biophys Res Commun 2008; 373:315–318.

- G Marquez-Ramirez, L Delaga-Buenrostro, I Chirino, et al. Titanium dioxide nanoparticles inhibit proliferation and induce morphological change and apoptosis in glial cells. Toxicol 2012; 302:146–156.

Author Info

Luma M Ibrahim1*, Raghdaa K Jassim1 and Ahmed Al Gabban2

1Department of Prosthodontics, College of Dentistry, University of Baghdad, Iraq2Department of Material Engineering, College of Dentistry, University of Baghdad, Iraq

Citation: Luma M Ibrahim, Raghdaa K Jassim, Ahmed Al Gabban,Biomechanical and Histomorphometric Analysis of Maxphase (Ti2AlC) Alloy as an Implant, J Res Med Dent Sci, 2022, 10 (8): 000-000.

Received: 11-Jul-2022, Manuscript No. JRMDS-22-66246; , Pre QC No. JRMDS-22-66246; Editor assigned: 13-Jul-2022, Pre QC No. JRMDS-22-66246; Reviewed: 27-Jul-2022, QC No. JRMDS-22-66246; Revised: 12-Sep-2022, Manuscript No. JRMDS-22-66246; Published: 20-Sep-2022