Research - (2020) Volume 8, Issue 1

Assessment of Surface Roughness and Surface Wettability of Laser Structuring Commercial Pure Titanium

*Correspondence: Aseel Mohammed Al-Khafaji, Department of Prosthodontics, College of Dentistry, University of Baghdad, Iraq, Email:

Abstract

Aim: To evaluate the commercial pure titanium disks that structuring by laser in two design (dot and groove) each one with three different laser scan (5, 15 and 25) and comparing with titanium surface that not subjected to any surface structuring (control) through measuring the wettability test and surface roughness test.

Materials and methods: Structuring on the surface of the commercial pure titanium (CP Ti) disks was performed via using fiber laser CNC machine in two design (dot and groove) in three different laser scans (5, 15 and 25), then the structuring disks analyzed with the control group by atomic force microscope and water contact angle test.

Results: The results of this study showed that the surface roughness and the wettability of commercial pure titanium disks for the dot and groove structuring design increased with the increasing of the laser scans. The result also show that laser structuring with dot design for any laser scan showed higher wettability and roughness values when compared to the groove design for the same laser scans.

Conclusion: The surface roughness and the wettability of the CP Ti disks increased when dot and groove design laser surface structuring were applied to the CP Ti disks especially at 25 laser scans.

Keywords

Laser surface structuring, Commercial pure titanium, Surface roughness, Surface wettability

Introduction

In a category of biomedical applications titanium has been greatly used and the most preferable materials especially for dental implants due to the good biostability, high biocompatibility, absent of toxicity, high corrosion resistance, good mechanical performance and long-term durability. Several studies in vitro and in vivo shown that the titanium surface topography of the implants has been to be crucial in improving the performance of implant [1–5].

The biomechanical fixation of implants and the rate of osseointegration have been notice increased when rough surface increased [6]. Aggregate roughness was the key reasons to increase surface properties of titanium implants. The rough surfaces were beneficial as they heighten attachment to bone tissue. The values of torque removal straight connected to rough surface implant help in mechanical joining and increase the surface zone, the objective of this action was to increase the surface wettability that increases implant hydrophilicity which would enhance the osseointegration via direct implant and newly formed bone communication [7-9]. Numerous methods can be used for surface structuring of the implant such as chemical etching, grit-blasting, plasma-spray, laser treatment, electrochemical treatment, and the combinations of the above methods [10–25].

The laser surface treatment can modifies the wettability and the topography of the titanium surface with no changing in the chemistry and the purity of titanium surface as well as comparing with the other modification techniques laser was clean, very fast, precision, non-contact and can be considered as redo protocol [2]. The laser technique formed surface with standard roughness, increase in the hardness, increase in the corrosion resistance and form oxides layer that cause increase the titanium biocompatibility [13,18,26-28].

The objective of this study was to evaluate the effect of the fiber laser CNC machine structuring on the commercial pure titanium disks in two design (dot and groove) each design with three different laser scans [5,15 and 25] and comparing with titanium surface that not subjected to any surface structuring (control) through measuring the water contact angle (wettability) test and surface roughness test.

Materials and Methods

Sample preparation

Small circular discs of commercially pure titanium (CP Ti) grade (II) (Orotig S rl EU Company, Italy) with diameter about 7 mm and 2 mm thickness was cut with wire cut machine (Knuth Smart DEM-Germany), then the disks smoothened into uniform smooth mirror appearance by using rotation machine with Sic Papers progressed from 500 till 2400 grit (2 minutes for each one). Then smooth disks are putted for 15 min in the ultrasonic cleaning device that full with ethanol then for 10 minutes in distilled water in order to removed debris and the contamination, lastly the disks were dried for 15 minutes at room temperature [29].

Laser surface structuring

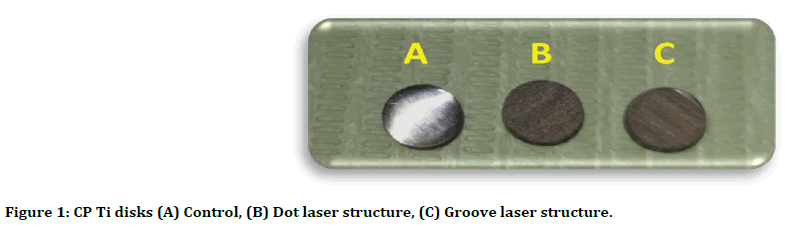

Roughening of the titanium surface has been build up by laser by means of prompting either dot surface structure or groove surface structure. The aim of this operation is to raise the bone titanium osseointegration via direct newly formed bone implant contact without any interpose layer of soft tissue. Structuring of the titanium surfaces were performed under normal atmosphere by utilizing fiber laser CNC machine (Jinan JinQiang 20W laser– China) with 1064 nm wavelength, 20 watt laser power and up to 7000 mm/sec scanning speed. Laser was structuring the dot design over the entire surface of the CP Ti disk, 0.01 mm was the space between each adjacent dots. For the groove design, also 0.01 mm was the space between each adjacent groove Figure 1. For the both design (the dot and the groove) 3 different laser scans [5,15,25] had been studied.

Figure 1. CP Ti disks (A) Control, (B) Dot laser structure, (C) Groove laser structure.

Corel Draw software Version X7 was utilized for drawing the dot and groove design profiles of the CP Ti disk surface. The disk was putted about 20 cm away from the laser source. When the system triggered on laser source starts shooting the sample with a continuous series of laser pulses in an ablation process to form the required structure. The laser system performed the desired profile on the titanium disk surface. After finishing the laser surface structuring, direct hand touched to the disk should not be done to prevent the contamination of dust and grease so sterile tweezers was used during movement of the specimens.

Sample grouping

The CP Ti disks were categorized into seven groups which are:

1. Control group without any laser structuring.

2. Dot laser structuring design with 5 laser scan (D-L 5).

3. Dot laser structuring design with 25 laser scan (D-L 15).

4. Dot laser structuring design with 25 laser scan (D-L 25).

5. Groove laser structuring design with 5 laser scan (G-L 5).

6. Groove laser structuring design with 15 laser scan (G-L 15).

7. Groove laser structuring design with 25 laser scan (G-L 25).

Surface roughness

Atomic force microscope (AA3000 Angstrom Advanced Inc., USA) was used to analyzed the surface roughness of the titanium disks that produced after laser surface structuring for the dot and groove designs for the different choose laser scans [5,15,25] as well as the control one. The Scanning probe of the atomic force microscope sees the average surface roughness for ten samples for each group.

Surface wettability test

Contact angle measuring device (Creating Nano Technologies Inc., Taiwan) was used to measure the surface wettability of the commercial pure titanium disks for the experiment and the control one (10 samples for each groups). Before the water contact angle measurements the disks were rinsed in acetone and then in isopropyl alcohol for 5 min for each solution then drying thoroughly. For prevent the transfer of other contaminants and oil from the skin to the samples it should be handle with forceps and gloved hands. The Contact angle measuring device was connected to computerized digital camera that capture an image after dropping of one single drop of distilled water (about 10 ul volume) on the surface of the examining disk by using of micro syringe. The time of capturing the images was 30 sec after placing the drop on the titanium surface; the measurements were performed at room temperature Figure 2.

Figure 2. Measurement of water titanium disk contact angle.

Results and Discussions

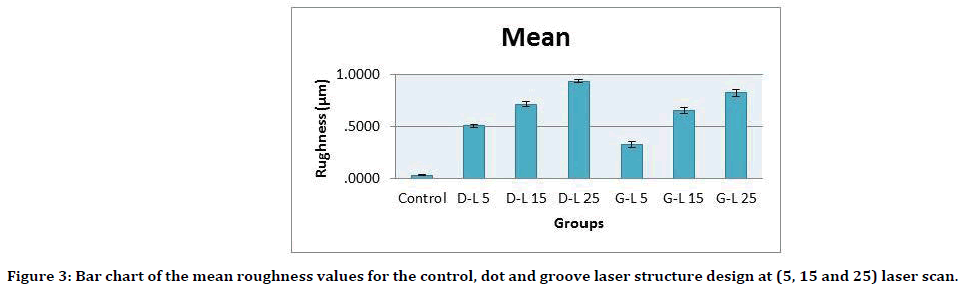

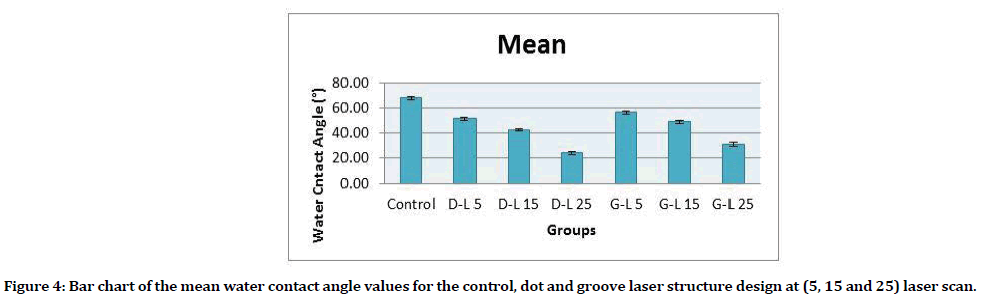

Atomic force microscope was used for analyzing the surface roughness. The mean roughness value for three different places of ten disks for all experimental and control groups are seen in Table 1 and Figure 3. While Table 2 and Figure 4 shows the means value of the water contact angle test for the experimental and control groups.

| Groups | Dot design | Groove design | |||||

|---|---|---|---|---|---|---|---|

| Control | D-L 5 | D-L 15 | D-L 25 | G-L 5 | G-L 15 | G-L 25 | |

| Mean | 0.027 | 0.502 | 0.71 | 0.933 | 0.322 | 0.651 | 0.821 |

| N | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Std. deviation | 0.0034 | 0.01383 | 0.02582 | 0.01767 | 0.02616 | 0.02601 | 0.03107 |

| Minimum | 0.02 | 0.48 | 0.67 | 0.91 | 0.27 | 0.61 | 0.78 |

| Maximum | 0.03 | 0.53 | 0.75 | 0.96 | 0.36 | 0.69 | 0.88 |

Table 1: Descriptive Statistics of the surface roughness (nm) values of the CP Ti disks of control and laser surface structuring disks.

| Groups | Dot design | Groove design | |||||

|---|---|---|---|---|---|---|---|

| Control | D-L 5 | D-L 15 | D-L 25 | G-L 5 | G-L 15 | G-L 25 | |

| Mean | 67.81 | 51.4 | 42.6 | 24.15 | 56.48 | 49 | 30.71 |

| N | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Std. Deviation | 0.9837 | 1.11952 | 1.21014 | 1.18063 | 1.17832 | 1.21106 | 1.73298 |

| Minimum | 66.2 | 49.9 | 40.7 | 22.7 | 54.8 | 47.2 | 28.2 |

| Maximum | 69.1 | 53.4 | 44.2 | 25.8 | 58.1 | 51.1 | 32.9 |

Table 2: Descriptive Statistics of the water contact angle (o) values of the CP Ti disks of the control and laser surface structuring disks.

Figure 3. Bar chart of the mean roughness values for the control, dot and groove laser structure design at (5, 15 and 25) laser scan.

Figure 4. Bar chart of the mean water contact angle values for the control, dot and groove laser structure design at (5, 15 and 25) laser scan.

The surface roughness for the polished control CP Ti samples show differences values from and laser structuring disks for the two designs of the 3 tested laser scans. The surface with highest roughness value was for the D-L 25 that showed the lowest water titanium contact angles follow by the G-L 25 then D-L 15, G-L 15, D-L 5, G-L 5 and lastly the control.

As the laser scans number increase the surface roughness increase and decrease in the water contact angle (increase the wettability) of the CP Ti disks. The water contact angle decrease when the laser scans increase this is may be due to the increasing in the titanium crevice process as the laser scans increase which cause increasing in surface roughness for the two experimental designs. Previous studies show that when the titanium surface was more wetting the adherence and proliferate of osteoblasts on titanium surface also increased [30,31] Because the hydrophilic surfaces formed best environments for cell adhesion comparing with the hydrophobic surfaces [32,33]. In the present study a close relationship is noticed between CP Ti disks roughness and wettability (hydrophilicity). So the laser surface structuring proved to be an efficient method for CP Ti surface modification in terms of increased roughness and increased hydrophilicity.

Hence it is necessary for the implant surface to be hydrophilic to induces rapid osseointegration [34,35]. The surface topography of laser structuring disks showed micropits which can be immediately influence the contact angles to decrease and changing the surface into an extremely hydrophilic surface, this increased the implant osseointegration of the laser structuring surfaces.

Conclusion

Laser surface structuring of the CP Ti were consider a successful method for surface topography modification of CP Ti. There is improvement in wettability of the CP Ti disk with increasing in the surface roughness after laser surface structuring in dot and groove design. Although the dot design shown best results than the groove design for the same laser scan the 25 laser scan showed more promising results than (15 and 5) laser scan.

Declaration of Interest

The authors declare no conflict of interest.

References

- Brunette DM, Tengvall P, Textor M, et al. Titanium in medicine: Material science, surface science, engineering, biological responses and Medical Applications, Springer, 2001.

- Sykaras N, Iacopino AM, Marker VA, et al. Implant materials, designs, and surface topographies: their effect on osseointegration. A literature review. Int J Oral Maxillofac Implants 2000; 15:675–690.

- Stanford CM. Surface modifications of dental implants. Aust Dent J 2008; 53:26-33.

- GÖkmenoglu C, Özmeric C, Akal G, et al. Coating of titanium implants with boron nitride by RF-magnetron sputtering. Bull Mater Sci 2016; 39:1363– 1370.

- Flemming RG, Murphy CJ, Abrams GA, et al. Effects of synthetic micro- and nano-structured surfaces on cell behavior. Biomaterials 1999; 20:573-588.

- Patil PS, Bhongade ML. Dental implant surface modifications: A review. J Dental Medi Sci 2016; 15:132-141.

- Eom TG, Jeon GR, Jeong CM, et al. Experimental study of bone response to hydroxyapatite coating implants: bone-implant contact and removal torque test. Oral Surg Oral Med Oral Pathol Oral Radiol 2012; 114:411–418.

- Rong M, Zhou L, Gou Z, et al. The early osseointegration of the laser-treated and acid-etched dental implants surface: An experimental study in rabbits. J Mater Sci Mater Med 2009; 20:1721–1728.

- Chung SH, Kim HK, Shon WJ, et al. Peri-implant bone formations around (Ti, Zr)O (2) -coated zirconia implants with different surface roughness. J Clin Periodontol 2013; 40:404–411.

- Cordioli G, Majzoub Z, Piatelli A, et al. Removal torque and histomorphometric investigation of 4 different titanium surfaces: An experimental study in the rabbit tibia. Int J Oral Maxillofac Implants 2000; 15:668-674.

- Bathomarco RV, Solorzano G, Elias CN, et al. Atomic force microscopy analysis of different surface treatments of Ti dental implant surfaces. Appl Surf Sci 2004; 233:29-34.

- Vanzillotta PS, Sader MS, Bastos IN, et al. Improvement in titanium bioactivity by three different surface treatments. Dent Mater 2006; 22:275.

- Gaggl A, Schultes G, Müller WD, et al. Scanning electron microscopical analysis of laser-treated titanium implant surfaces: A comparative study. Biomaterials 2000; 21:1067-1073.

- Ricci JL, Alexander H. Laser microtexturing of implant surfaces for enhanced tissue integration. Key Eng Mater 2001; 199:179–202.

- Stangl R, Rinne B, Kastl S, Hendrich C. The influence of pore geometry in cp Ti-implants—A cell culture investigation. Eur Cells Mater 2001; 2:1–9.

- Joób-Fancsaly A, Divinyi T, Fazekas A, et al. Pulsed laser-induced micro-and nanosized morphology and composition of titanium dental implants. Smart Mater Struct 2002; 11:819.

- Petõ G, Karacs A, Paszti Z, et al. Surface treatment of screw shaped titanium dental implants by high intensity laser pulses. Appl Surf Sci 2002; 186:7-13.

- Bereznai M, Pelsoczi I, Toth Z, et al. Surface modifications induced by ns and sub-ps excimer laser pulses on titanium implant material. Biomaterials 2003; 24:4197- 4203.

- Karacs A, Joob-Fancsaly A, Divinyi T, et al. Morphological and animal study of titanium dental implant surface induced by blasting and high intensity pulsed Nd-glass laser. Mater Sci Eng 2003; 23:431-435.

- Hallgren C, Reimers H, Chakarov HD, et al. An in vivo study of bone response to implants topographically modified by laser micromachining. Biomaterials 2003; 24:701-710.

- Cho SA, Jung SK. A removal torque of the laser: Treated titanium implants in rabbit tibia. Biomaterials 2003; 24:4859-4863.

- Trtica M, Gakovic B, Batani D, et al. Surface modification of a titanium implant by a picosecond Nd:YAG laser operating at 1046 and 523 nm. Appl Surf Sci 2006; 253:2551.

- Ronold HJ, Lyngstadaas SP, Ellingsen JE. Analysing the optimal value for titanium implant roughness in bone attachment using a tensile test. Biomaterials 2003; 24:4559-4556.

- Chauvy PF, Hoffman P, Landolt D. Applications of laser lithography on oxide film to titanium micromachining. Appl Surf Sci 2003; 209:165-170.

- Jaeggi C, Kern P, Michler J, et al. Anodic thin films on titanium used as masks for surface micropatterning of biomedical devices. Surf Coat Technol 2005; 200:1913-1919.

- Paz MD, Álava JI, Goikoetxea L, et al. Biological response of laser macrostructured and oxidized titanium alloy: an in vitro and in vivo study. J Appl Biomater Biomech 2011; 9:214–222.

- Dahotre NB, Paital SR, Samant AN, et al. Wetting behavior of laser synthetic surface microtextures on ti-6al-4v for bioapplication. Phil Trans R Soc 2010; 368:1863-1889.

- Kurella NB, Dahotre A. Review paper: Surface modification for bioimplants: The role of laser surface engineering. J Biomater Appl 2005; 20:5–50.

- Safi IN. Physiological dental implant prepared by stem cells with β-TCP coated titanium and zirconia implants. PhD thesis, College of Dentistry, University of Baghdad, 2019.

- Lampin M, Warocquier Clerout R, Legris C, et al. Correlation between substratum roughness and wettability, cell adhesion and cell migration. J Biomed Mater Res 1997; 36:99-108.

- Ponsonnet L, Reybier K, Jaffrezic N, et al. Relationship between surface properties (roughness, wettability) of titanium and titanium alloys and cell behavior. Mater Sci Eng 2003; 23:551-560.

- Nanci A, Zalzal S, Gotoh Y, et al. Ultrastructural characterization and immunolocalization of osteopontin in rat calvarial osteoblast primary cultures. Microsc Res Tech 1996; 33:214-231.

- Charles PD, Anandapandian PA, Samuel S. Osteogenic potential of laser modified and conditioned titanium zirconium surfaces. J Indian Prosthodon 2016; 16:1-7.

- Zhao G, Schwartz Z, Wieland M, et al. High surface energy enhances cell response to titanium substrate microstructure. J Biomed Mater Res 2005; 74:49-58.

- Rupp F, Scheideler L, Olshanska N, et al. Enhancing surface free energy and hydrophilicity through chemical modification of microstructuredti tanium implant surfaces. J Biomed Mater Res 2006; 76:323-331.

Author Info

Department of Prosthodontics, College of Dentistry, University of Baghdad, IraqCitation: Aseel Mohammed Al-Khafaji, Thekra Ismael Hamad, Assessment of Surface Roughness and Surface Wettability of Laser Structuring Commercial Pure Titanium, J Res Med Dent Sci, 2020 8(1):81-85.

Received: 28-Dec-2019 Accepted: 20-Jan-2020